Air-cooled absorption type refrigerating plant

An absorption refrigeration and air cooling technology, which is applied in adsorption machines, boiler absorbers, absorbents/adsorbents, etc., can solve the problems of ensuring the maintenance space, the difficulty of ensuring the suction space of the air intake port, and the large-scale device body. Achieve the effect of ensuring the heat release area, reducing the air resistance, and reducing the installation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, the best embodiment of the invention of the present application will be described with reference to the attached drawings.

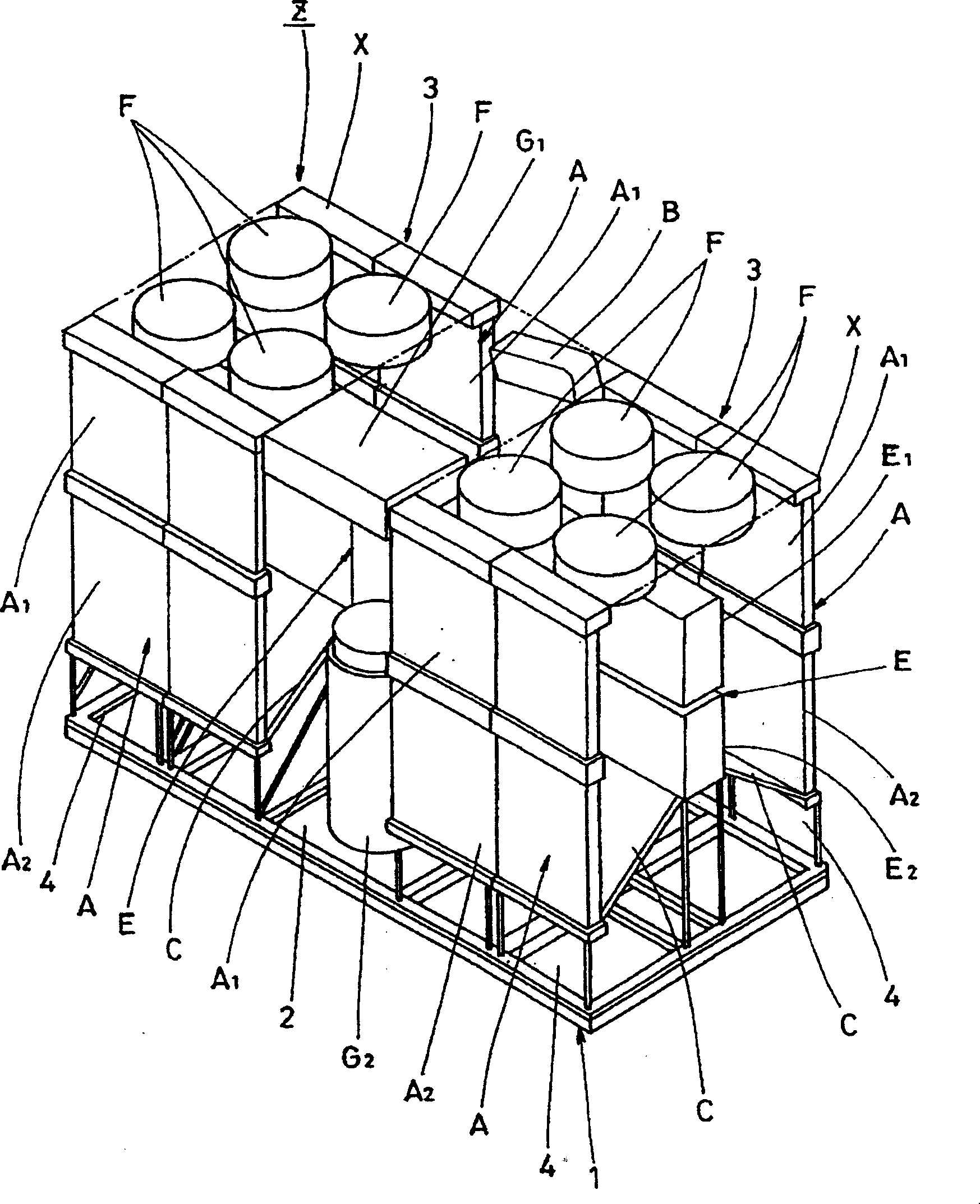

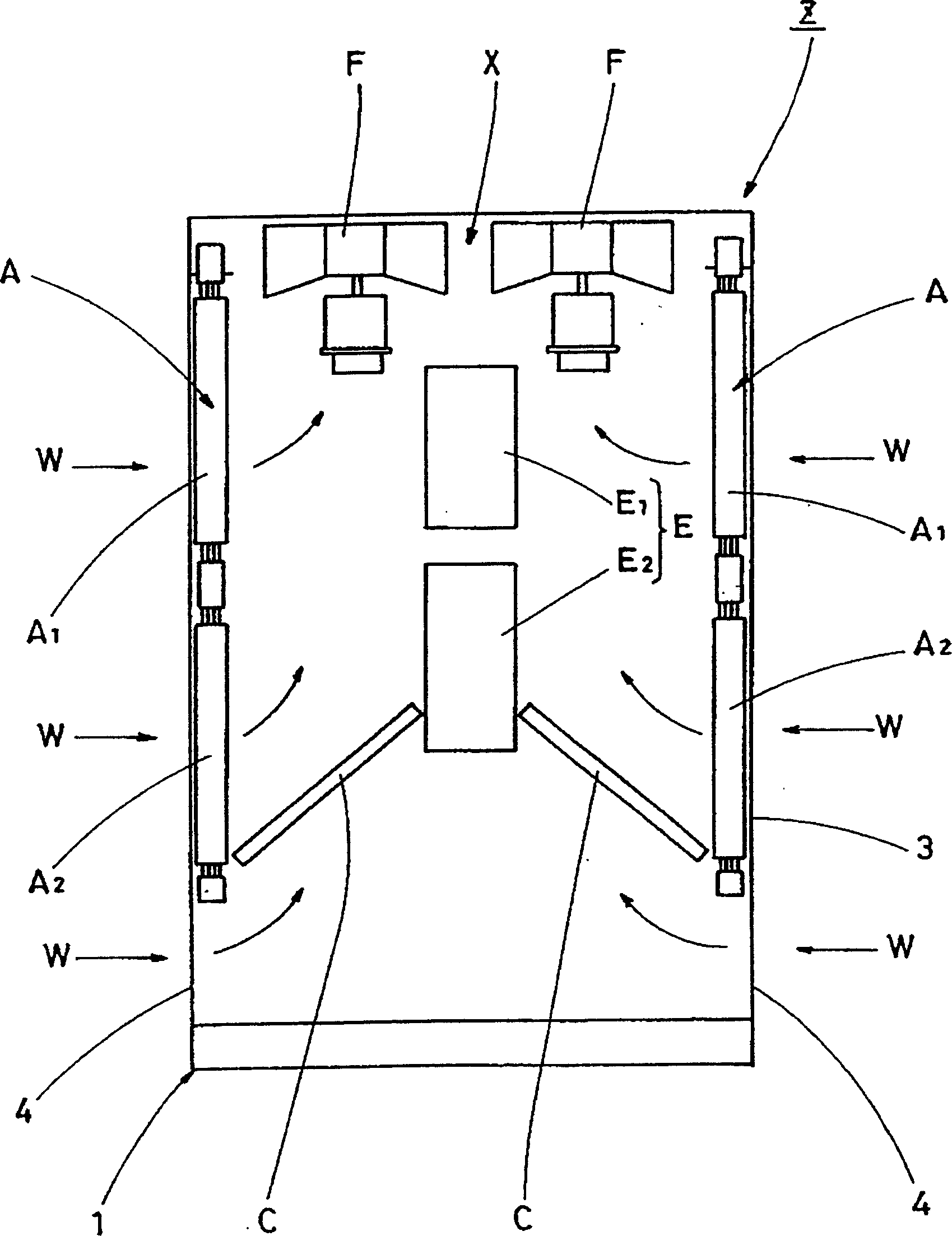

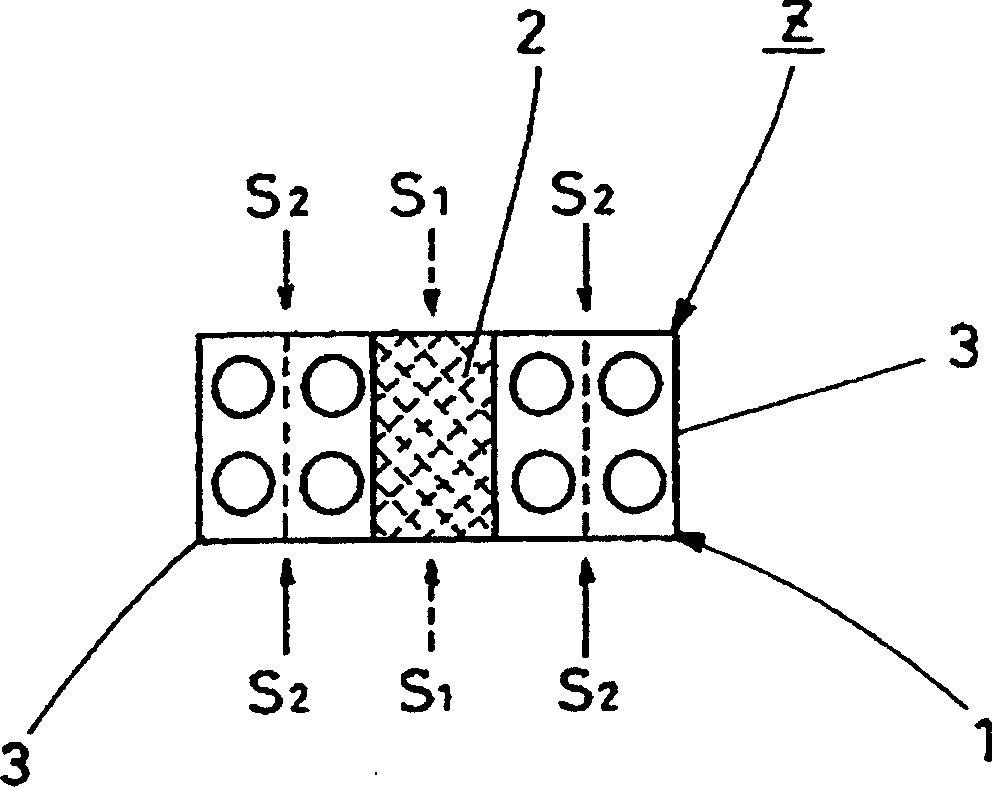

[0035] This air-cooled absorption freezer, such as figure 1 and figure 2 As shown, it includes: a machine room 2 located in the center of the longitudinal direction of the approximately cuboid device body 1 and air cooling and heat exchange parts 3 and 3 arranged on both sides of the machine room 2 in the longitudinal direction.

[0036] In the above-mentioned machine room 2, there are disposed: a high-temperature regenerator G2 located at the lower stage on one side of the device body 1, a low-temperature regenerator G1 located at the upper stage, and a heating chamber located at the upper stage on the other side of the device body 1. heat exchanger B. And, between this machine room 2 and the air cooling and heat exchanging parts 3, 3, although not shown in the figure, a partition wall is provided. This facilitates maintenance of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com