Fully automated test system for hot plugging of external devices

A technology of fully automated testing and external equipment, applied in faulty hardware testing methods, error detection/correction, faulty computer hardware detection, etc., can solve long test time, fatigue of testers, inaccurate records of hot plug times, etc. problem, to achieve accurate judgment and liberate human effect

Inactive Publication Date: 2018-07-13

HUIZHOU DESAY SV AUTOMOTIVE

View PDF4 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Manual operation is more convenient and quick, but the disadvantages are exposed - it takes a long time to test, and the long-term hot-swapping operation makes the testers fatigue, the time of the hot-swapping and unplugging process cannot be accurately controlled, and the hot-swapping Inaccurate recording of plugging times, etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

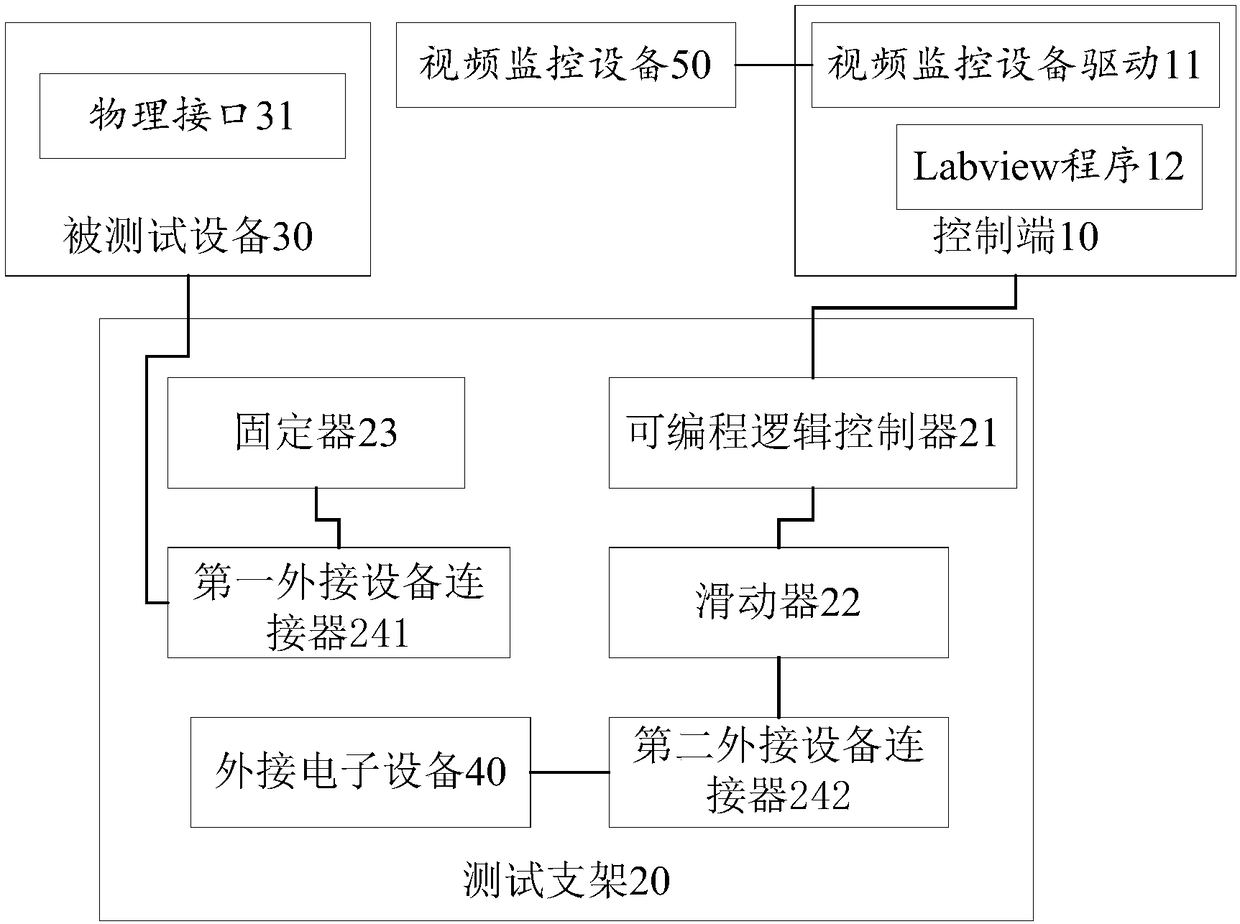

[0022] This embodiment provides a fully automated test system for hot plugging of external devices, such as figure 1 As shown, it includes a video monitoring device 50, a control terminal 10, a test bracket 20, and a device under test 30 connected in sequence, wherein,

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

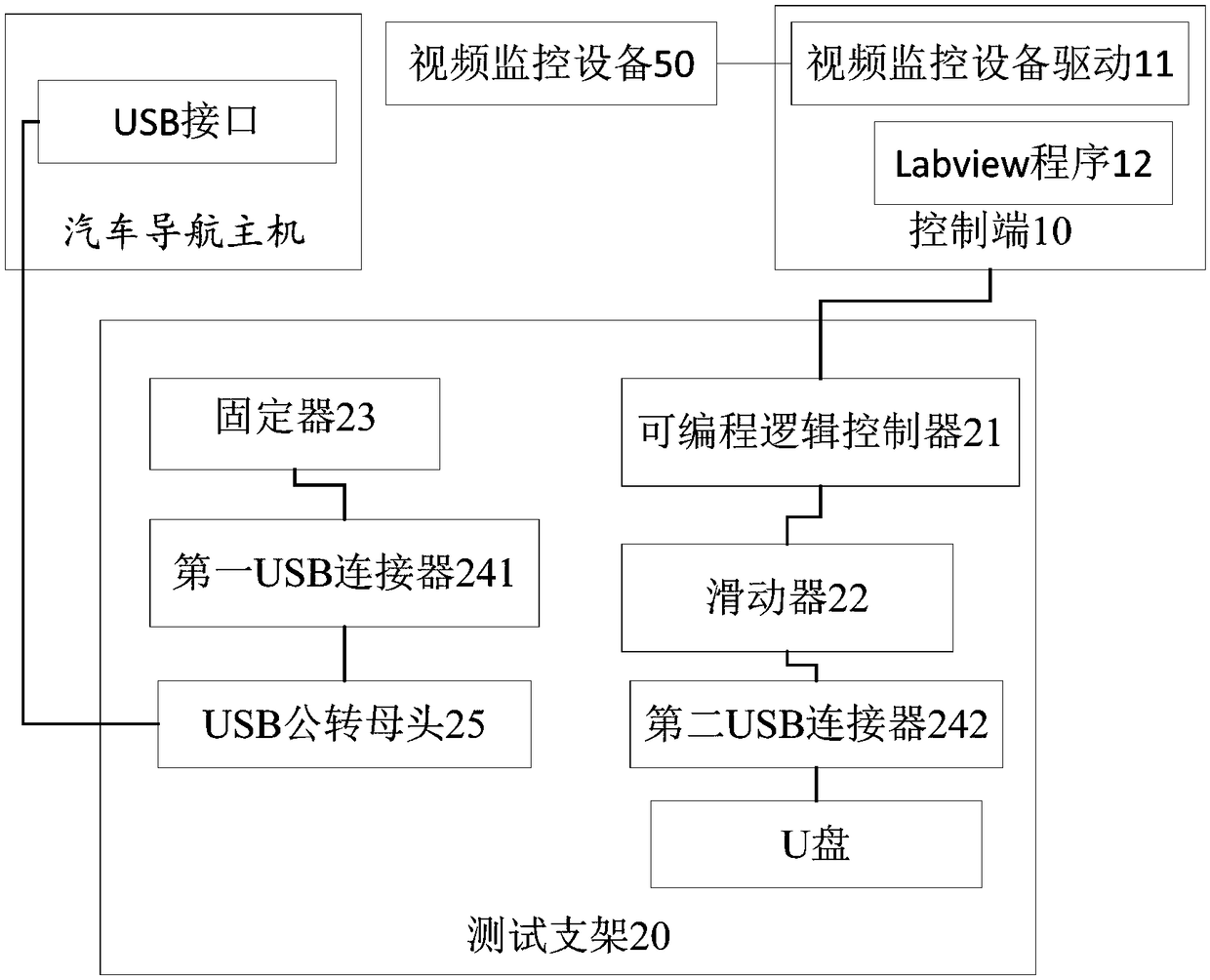

The invention relates to the field of automated testing, and discloses a fully automated test system for hot plugging of external devices. The system comprises a video monitoring device, a control end, a testing supporting frame and a to-be-tested device which are sequentially connected, wherein the to-be-tested device is provided with a display interface for displaying the inserting and pulling states of the to-be-tested device when the to-be-tested device is connected with the external electronic devices; the video monitoring device is used for monitoring the display interface of the to-be-tested device in real time; a video monitoring device drive is installed on the control end, and video recording parameters of the video monitoring device are adjusted and a photographing state is controlled through the control end to perform replaying of recorded videos and photographed images; the external electronic devices are fixed on the testing supporting frame, and the testing supporting frame is used for simulating the hot plugging between the external electronic devices and the to-be-tested device; the control end is used for transmitting testing parameters and operational instructions to the testing supporting frame and displaying testing results. By means of the system, the testing efficiency and accuracy are improved, and the cost is reduced.

Description

technical field [0001] The invention relates to the field of automatic testing, in particular to a fully automatic testing system for hot plugging of external equipment. Background technique [0002] In the electronic devices we use daily, due to the limitations of the electronic devices themselves or for the convenience of users to carry and use, external devices are often required for capacity expansion and sound listening, such as U disk, earphones, etc. [0003] And testers usually can only do manual operation when testing the hot plug of external devices. For example, for the USB function of car navigation, the U disk needs to be connected externally. Since the U disk is purchased and used separately by the user, we need to simulate the actual use of the user for testing, and perform hot-swapping operations on the external U disk to detect the identification of the device. Manual operation is more convenient and quick, but the disadvantages are exposed - it takes a lon...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G06F11/22G06F13/40

CPCG06F11/221G06F11/2273G06F13/4081

Inventor 张玉玲包丹马芬妮施翠玲

Owner HUIZHOU DESAY SV AUTOMOTIVE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com