Patents

Literature

50results about How to "Realize fully automated testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

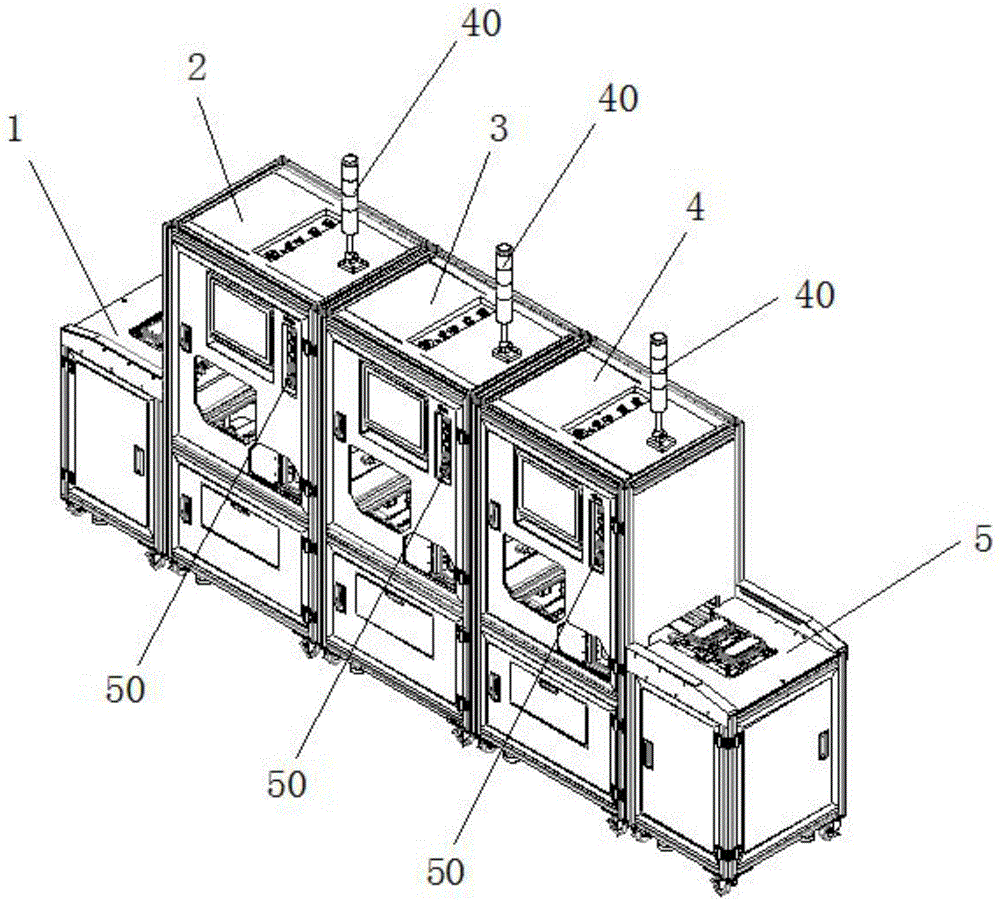

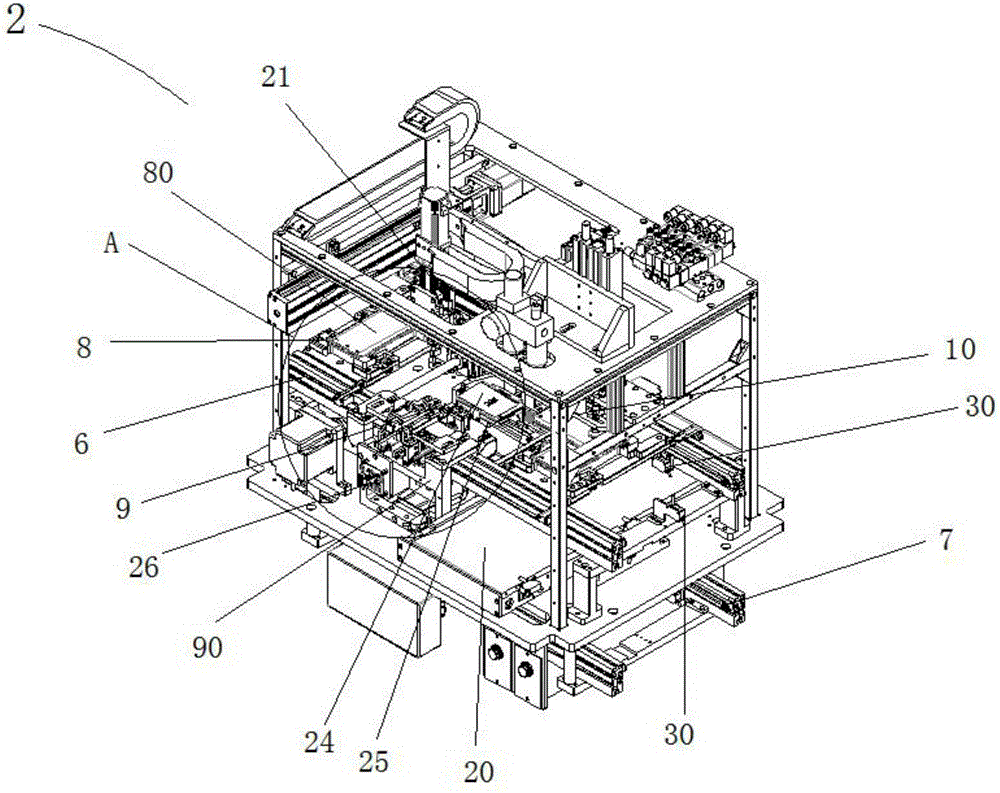

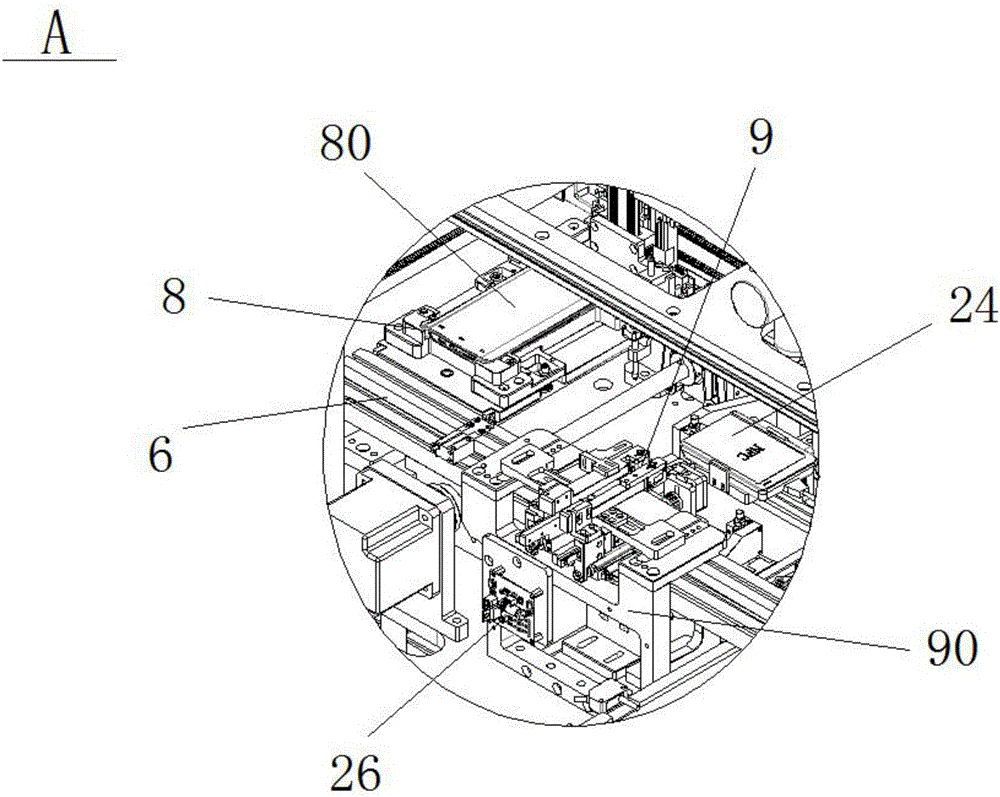

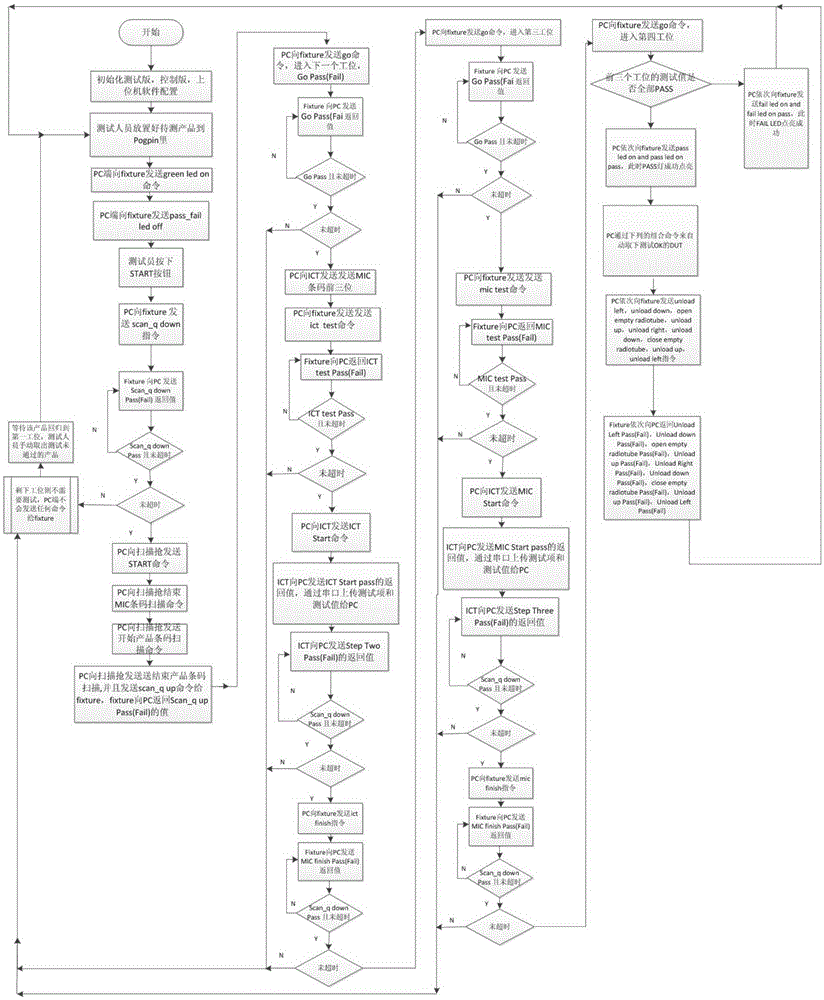

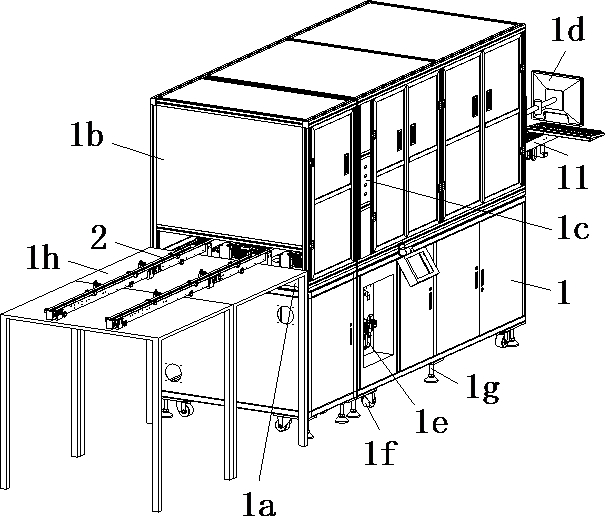

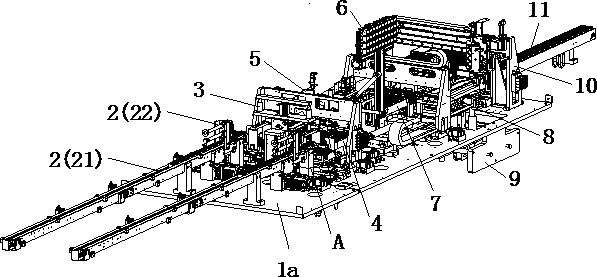

Automatic assembly line type cellphone online testing method and system

ActiveCN106092210AAccurate transmissionImprove accuracyMeasurement devicesSubstation equipmentTest efficiencyTestware

The invention discloses an automatic assembly line type cellphone online testing method, and the method comprises the following steps: (1), implanting testing software in a plurality of to-be-tested cellphones; (2), preparing an automatic assembly line type cellphone online testing system; (3), enabling the to-be-tested cellphones to be placed on a testing carrier, wherein the to-be-tested cellphones is driven by the upper conveying rail to move to a testing machine bench along with the testing carrier; (4), enabling a PC to transmit an AT instruction to built-in testing software in the to-be-tested cellphones through a testing communication model, enabling a PLC to drive the testing machine bench to carry out one operation for the to-be-tested cellphones according to the content of the AT instruction, and enabling the testing software to test the functions of the to-be-tested cellphones; (6), taking out the to-be-tested cellphones after the detection is finished, enabling the testing carrier to move to the lower end of a feeding bench along with a lower conveying rail, and enabling a front end lifting platform to lift the testing carrier back to the feeding bench. The method is quick and accurate in testing instruction transmission, improves the testing efficiency, is quick and precise in testing, and reduces the testing time.

Owner:广东每通测控科技股份有限公司

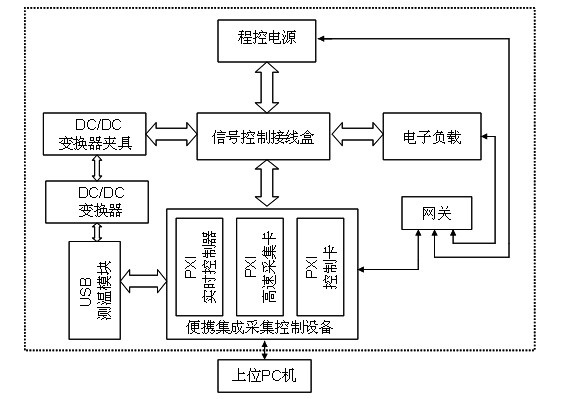

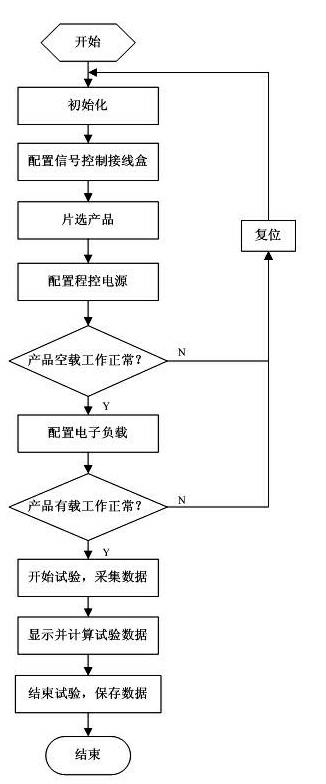

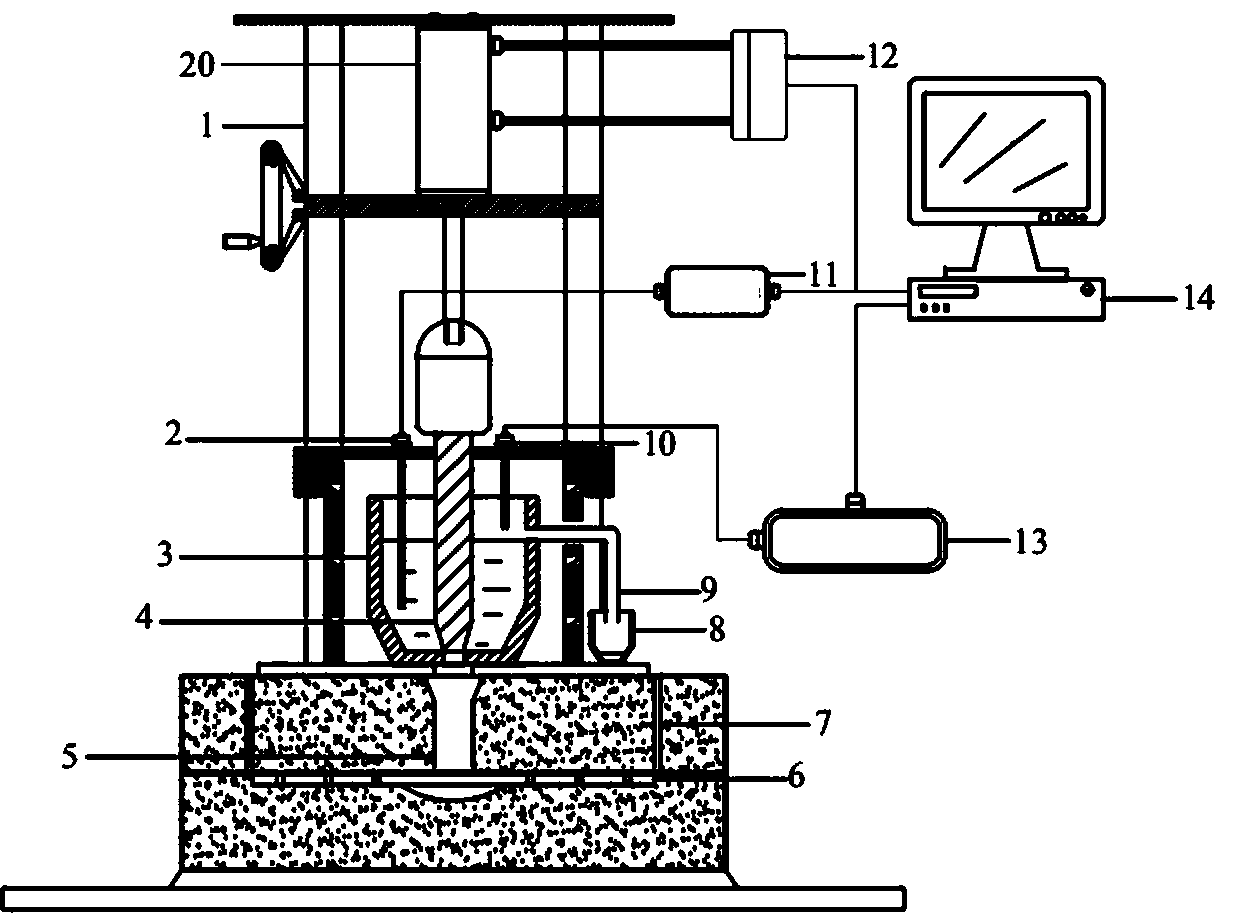

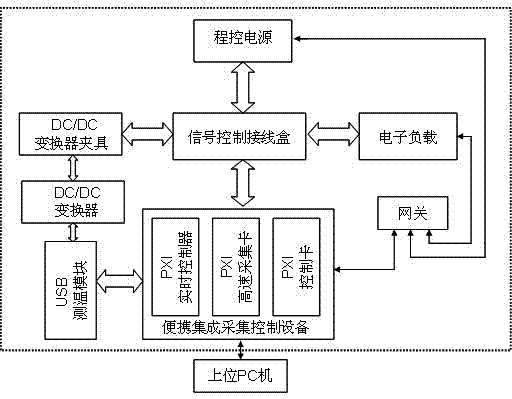

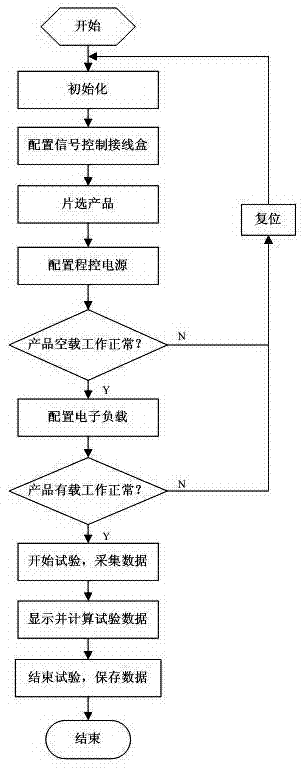

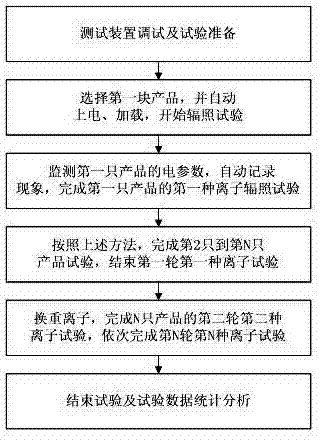

Automatic test system for single event effect test of DC/DC (direct current/direct current) converter and test method

ActiveCN102539982AImprove test efficiencyRealize fully automated testingElectrical testingTestwareDc converter

The invention discloses an automatic test system for a single event effect test of a DC / DC (direct current / direct current) converter. The automatic test system comprises a programmable power supply, a PXI integrated sampling control unit which is connected with an electrical parameter signal control terminal box, an upper PC (personal computer) which is connected with the PXI integrated sampling control unit, and a LabVIEW test software for monitoring an electrical parameter signal and analyzing and processing the electrical parameter signal. The invention also discloses a test method for the automatic test system. By the automatic test system and the test method, the single event effect test data of the DC / DC converter can be tested fully automatically, automatic high-speed data acquisition, automatic product selection, automatic product loading, automatic power setting, test parameter setting, real-time acquired data display and data replay are integrated, the single event effect test efficiency of the DC / DC converter is greatly improved, and the damage to the body of a tester who enters a radiation room repeatedly during the test can be avoided.

Owner:NO 43 INST OF CHINA ELECTRONICS TECH GRP CETC

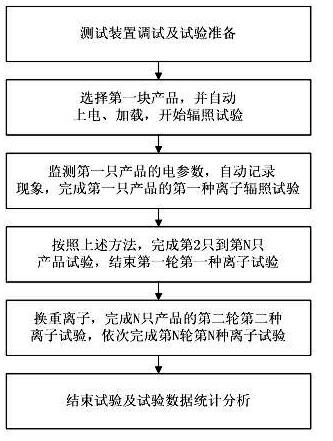

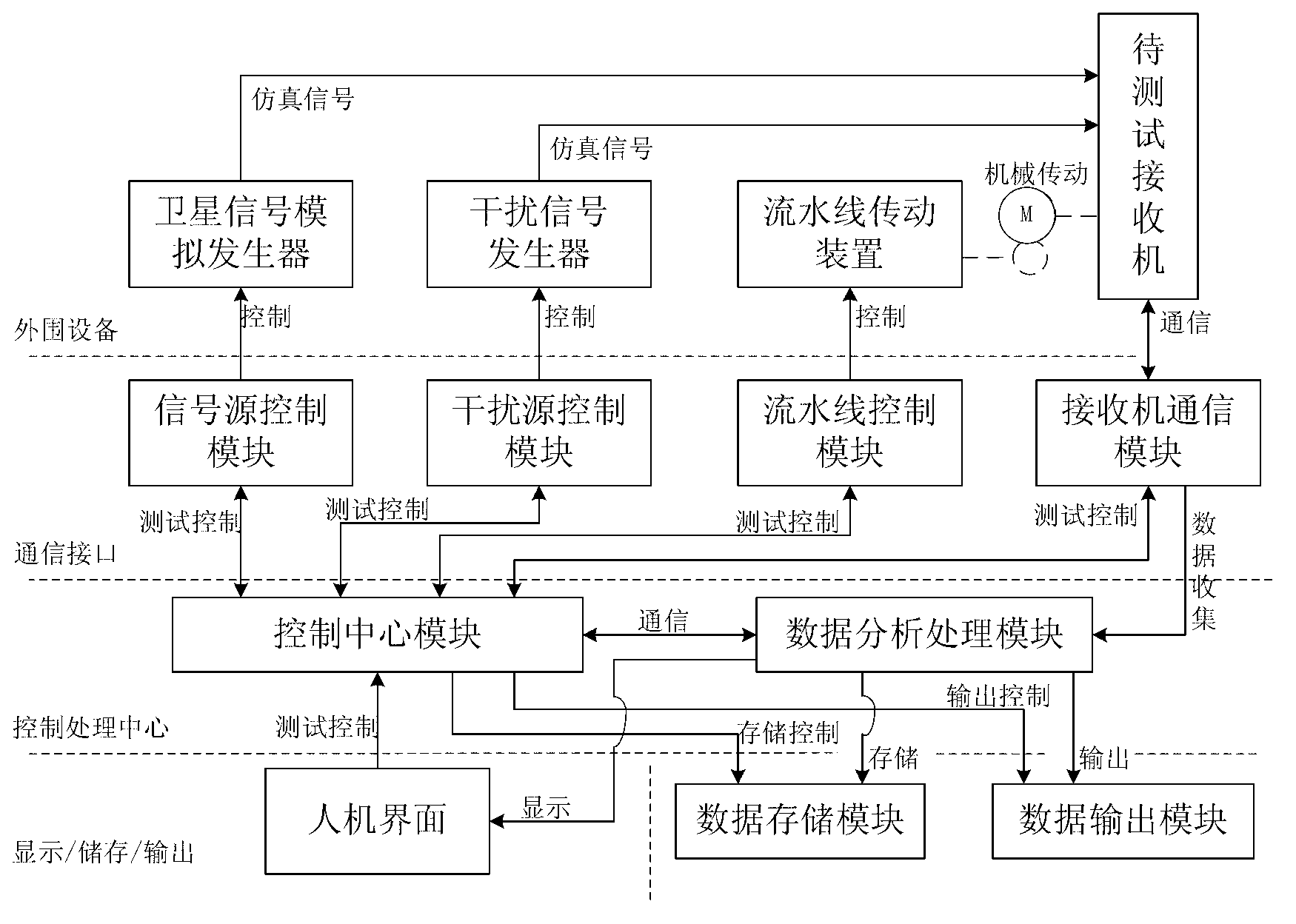

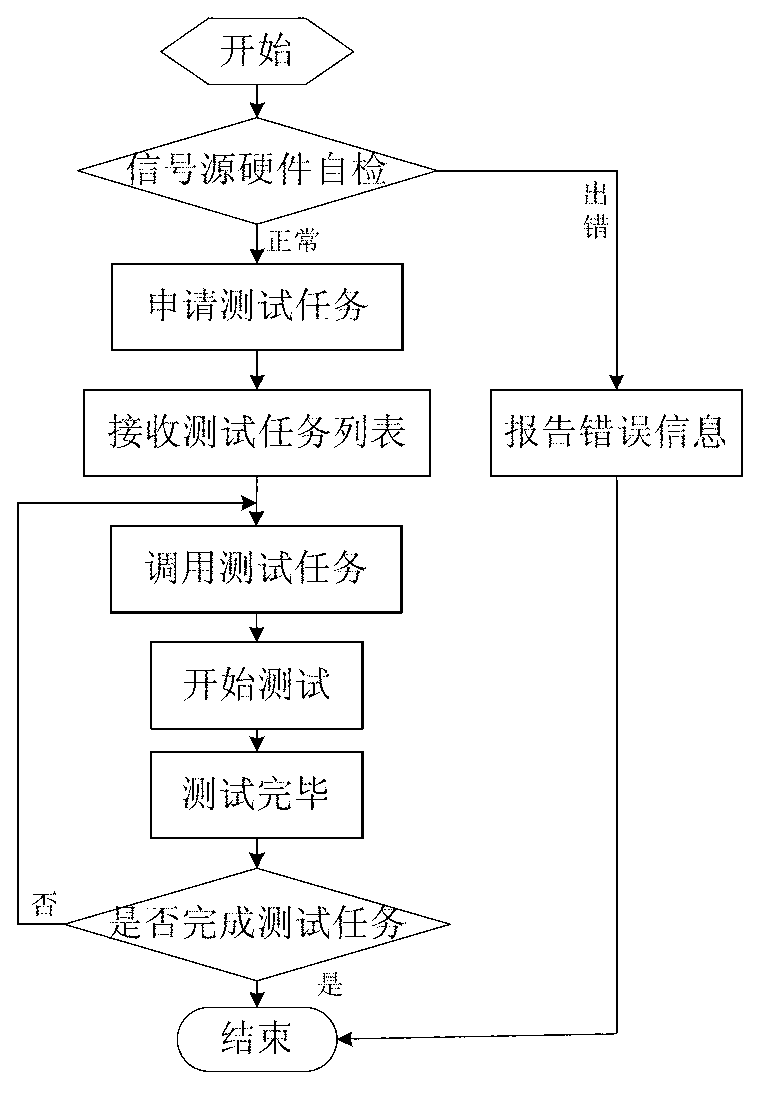

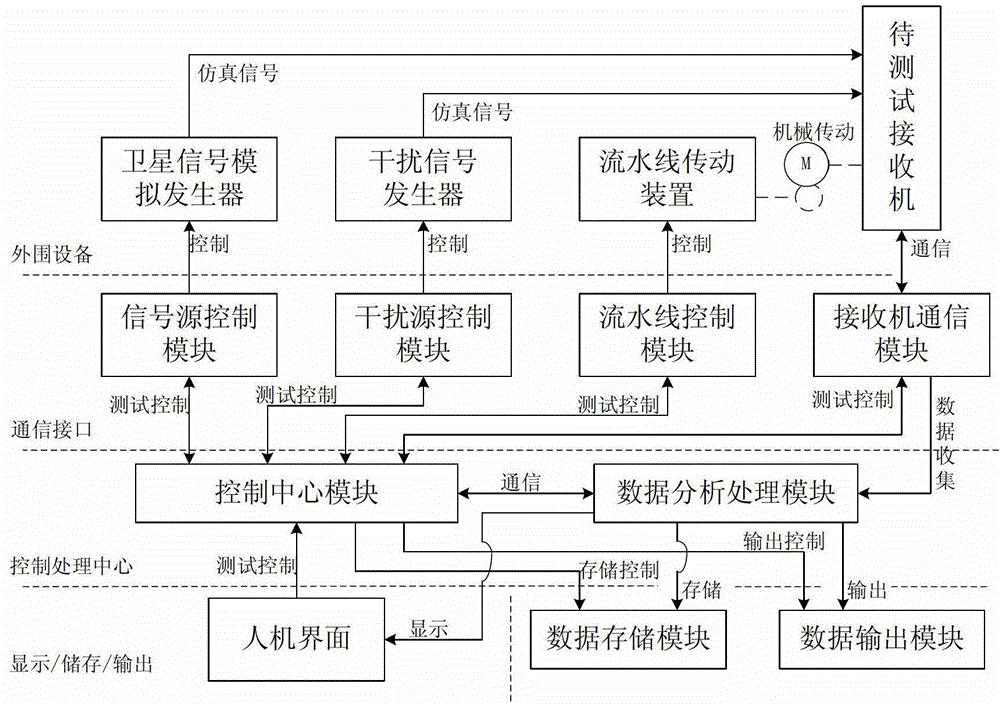

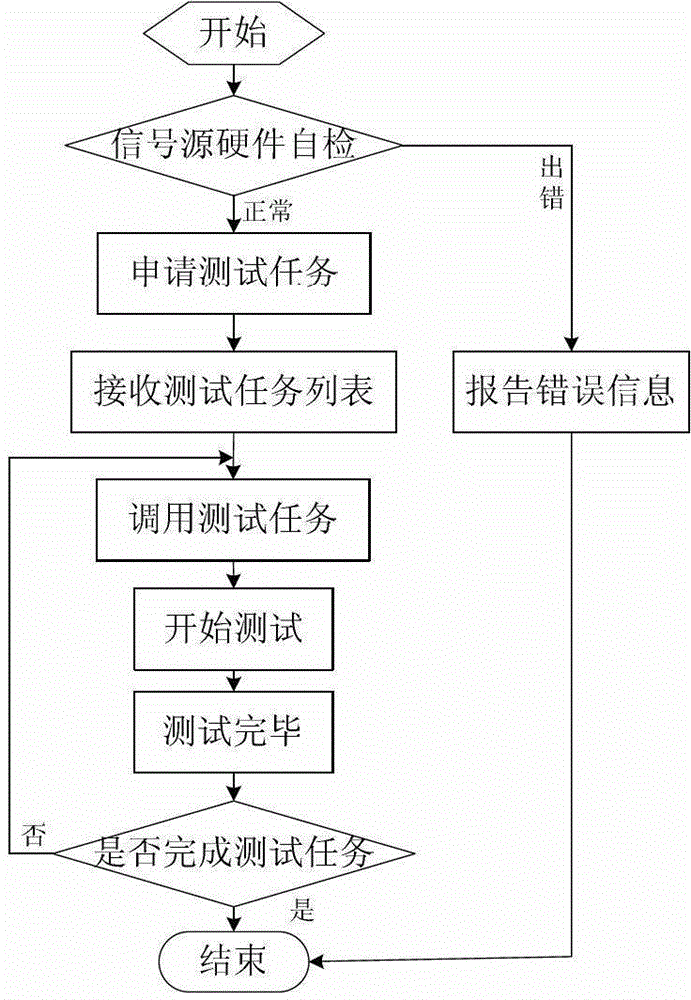

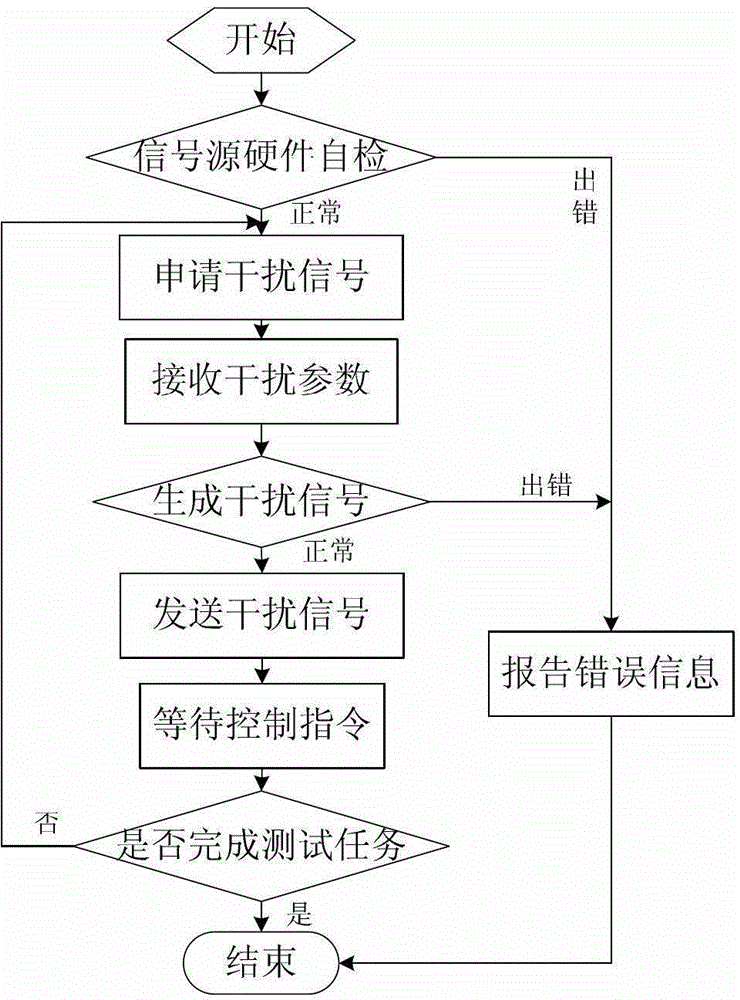

Batch automated testing method for navigation terminal receiver

ActiveCN103293536AShort working hoursOperational impactSatellite radio beaconingComputer terminalAssembly line

The invention relates to a batch automated testing method for a navigation terminal receiver. The batch automated testing method mainly aims at batch navigation receiver testing tasks and quick batch test for batch production of the navigation terminal receiver. Without involvement of an operator or many operators, the batch automated testing method has the advantages of high accuracy, consistency, efficiency and low cost and the like and is mainly applied to analog simulation generation technique of satellite navigation signals, bussing technique, assembly line based testing technique, sampling technique and database storage technique and automatic generation technique of test result report forms.

Owner:BEIHANG UNIV

Terminal test equipment and method

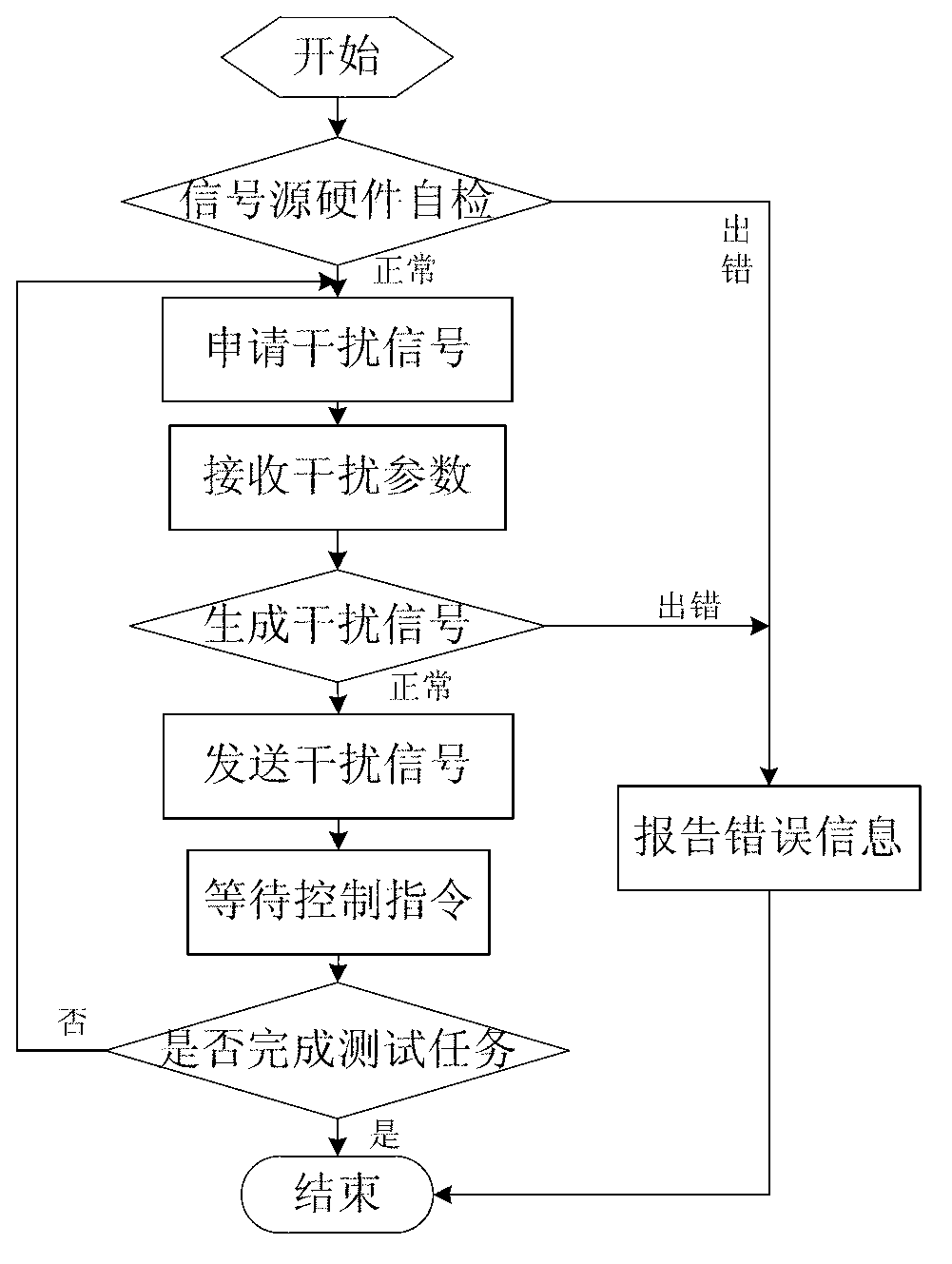

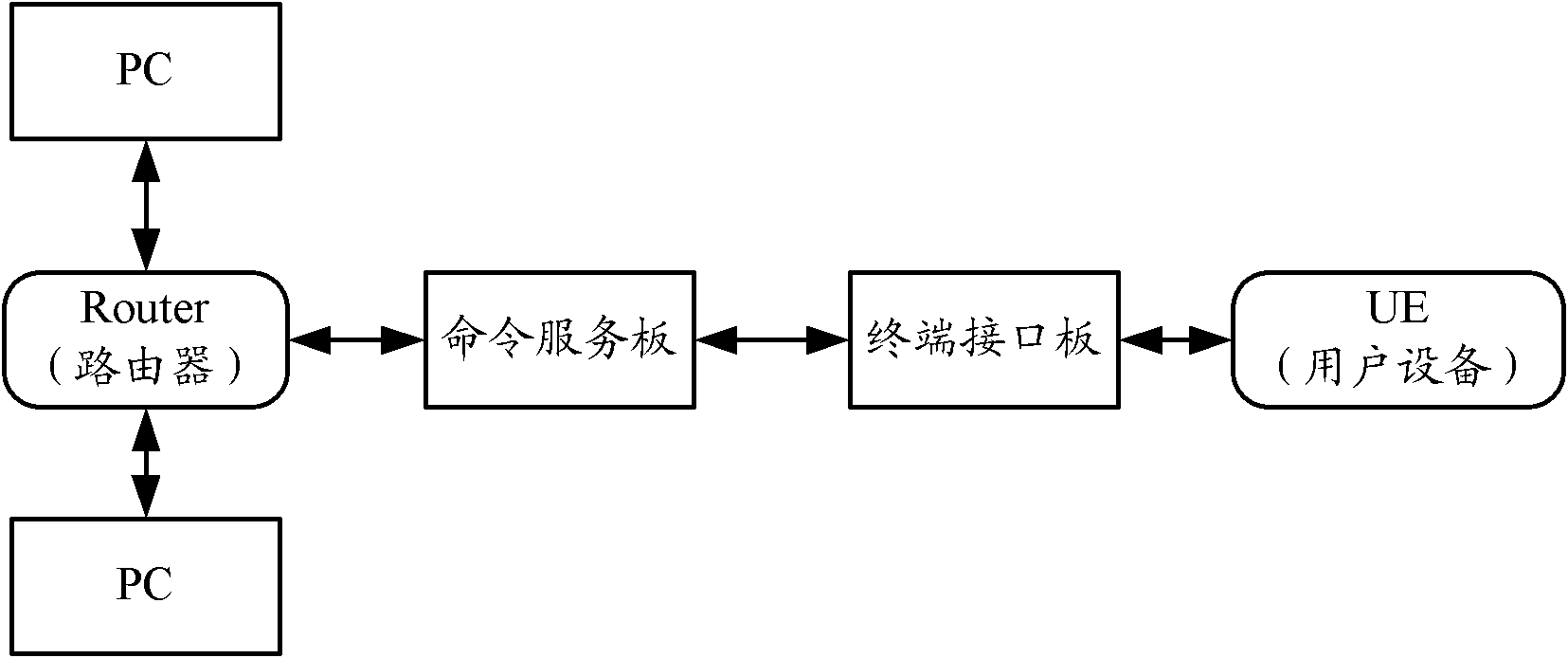

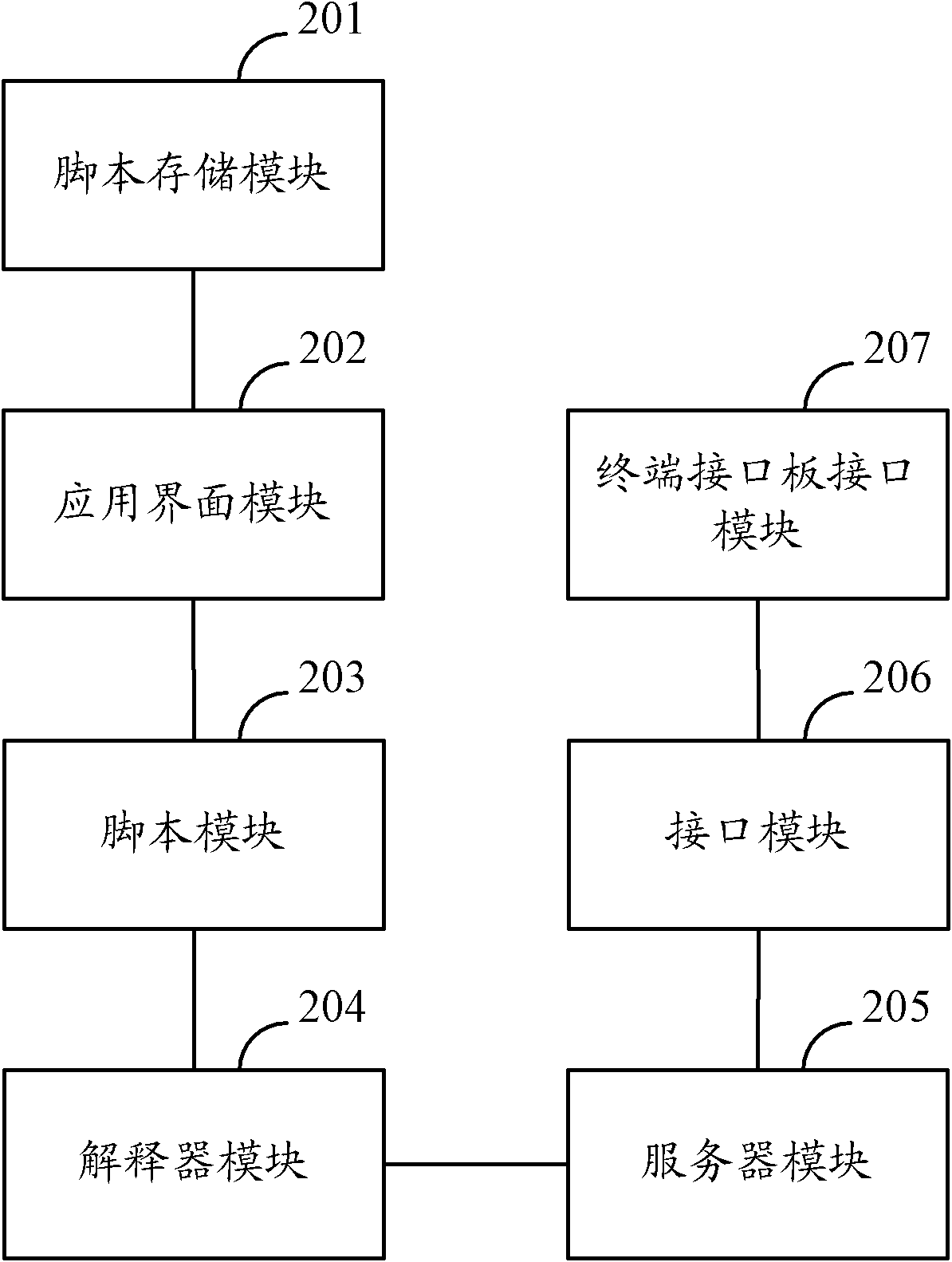

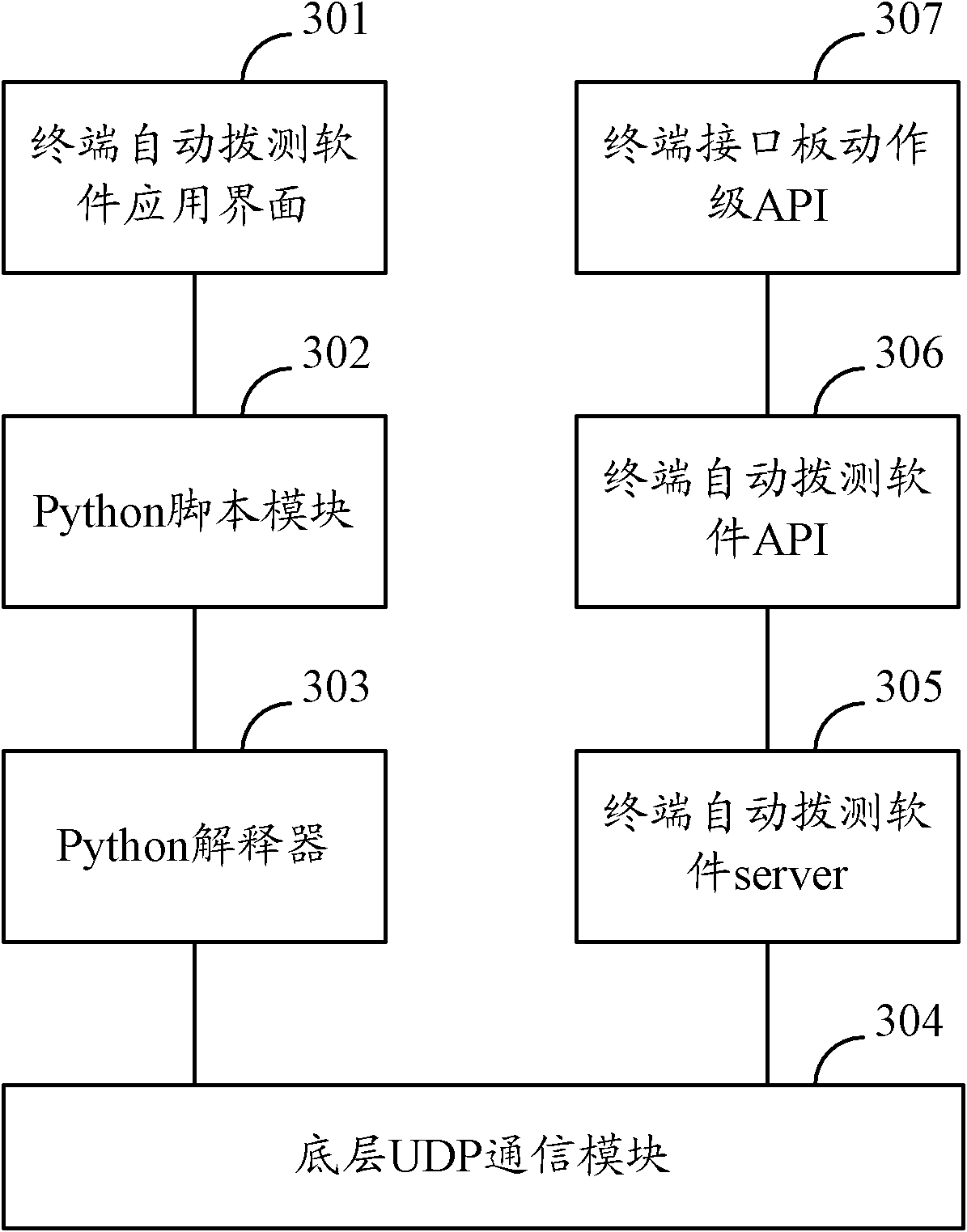

ActiveCN102468993ARich automated testing functionsRealize fully automated testingData switching networksTestwareUser Datagram Protocol

The invention discloses a terminal test equipment and method. The terminal test method comprises the following steps: executing a script selected by a user, encapsulating a command generated in the process of executing the script into a UDP (user datagram protocol) packet; converting the UDP packet into which the script is encapsulated into a recognizable command; calling a defined terminal action function according to the command; encapsulating the command to be executed by a terminal into TCP or UDP message in the form of a character string which can be recognized by the terminal according to the calling, and sending to the terminal; and presenting the script execution result to the user. According to the terminal test equipment and method, the fully automatic terminal test is realized without adopting manual operation, and the automatic test with combination of various number terminals, services and operations is realized. The terminal test equipment can be combined with other automatic test software, thus the automatic test function can be expanded and enriched.

Owner:DATANG MOBILE COMM EQUIP CO LTD

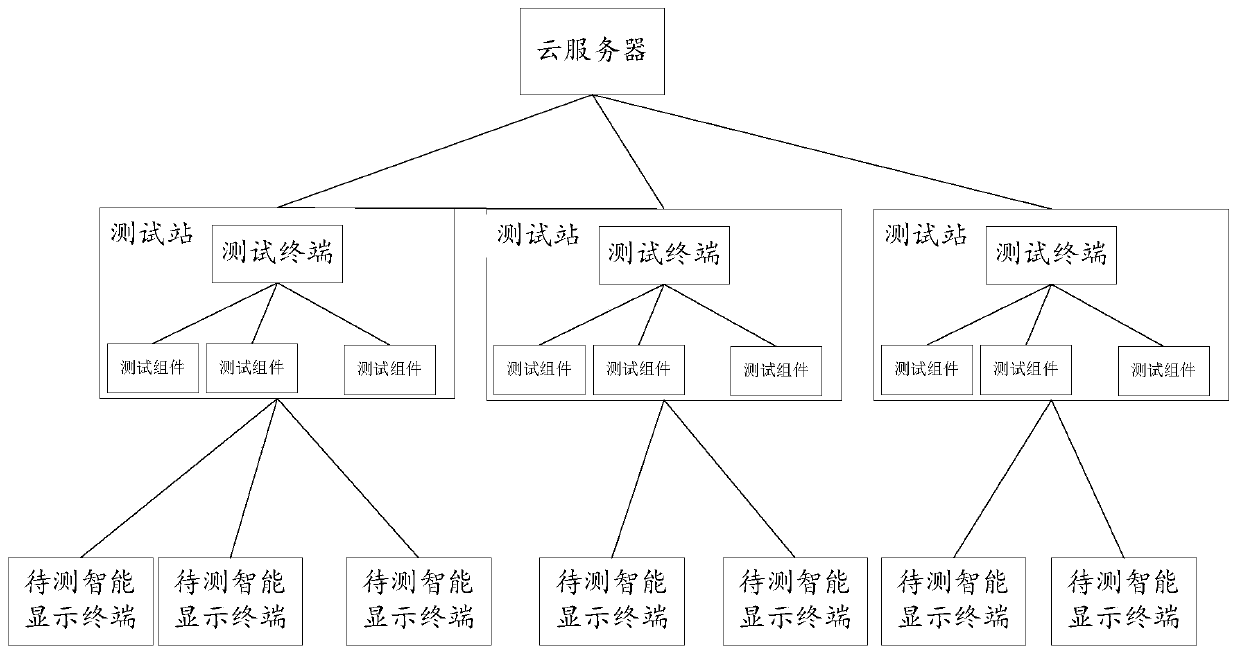

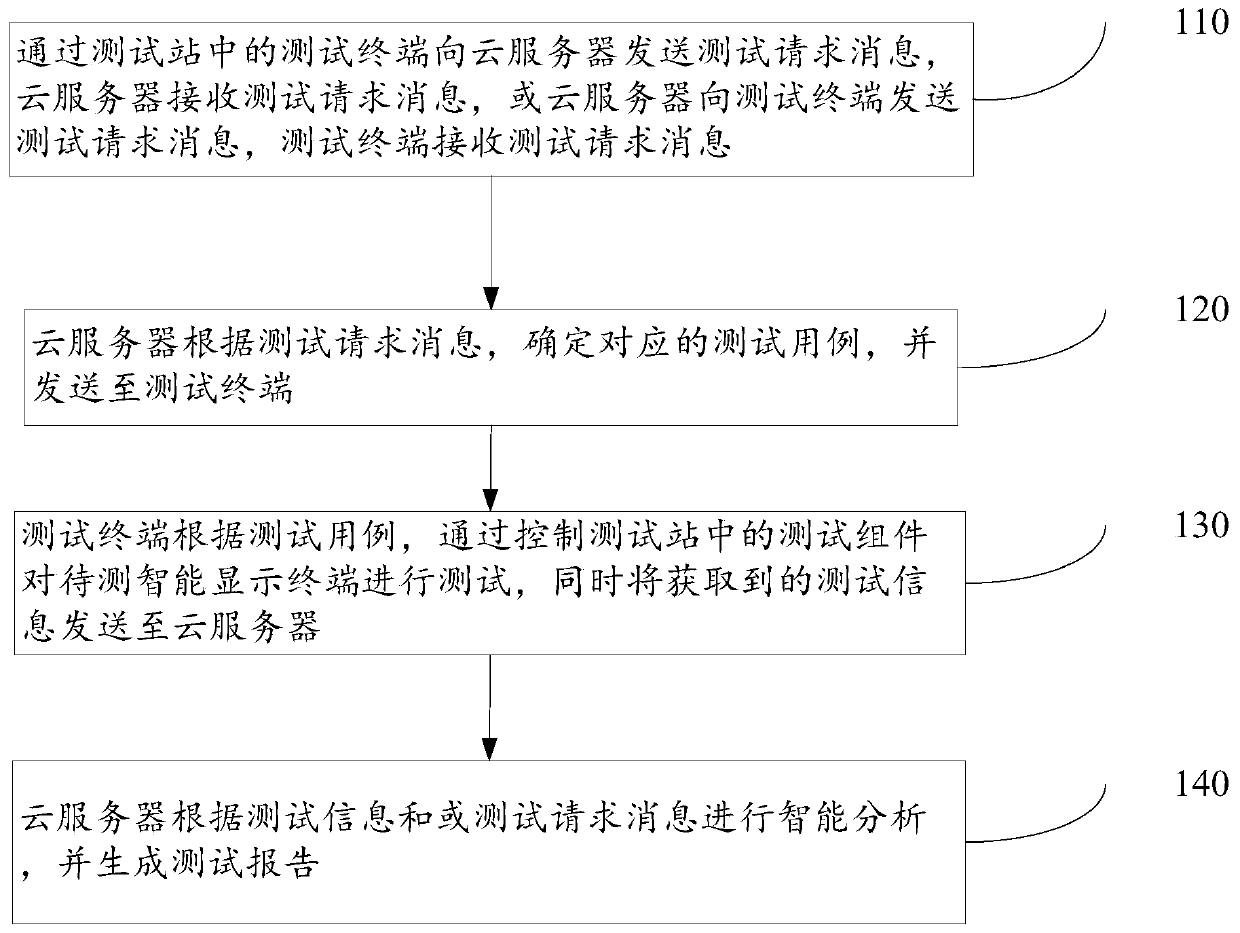

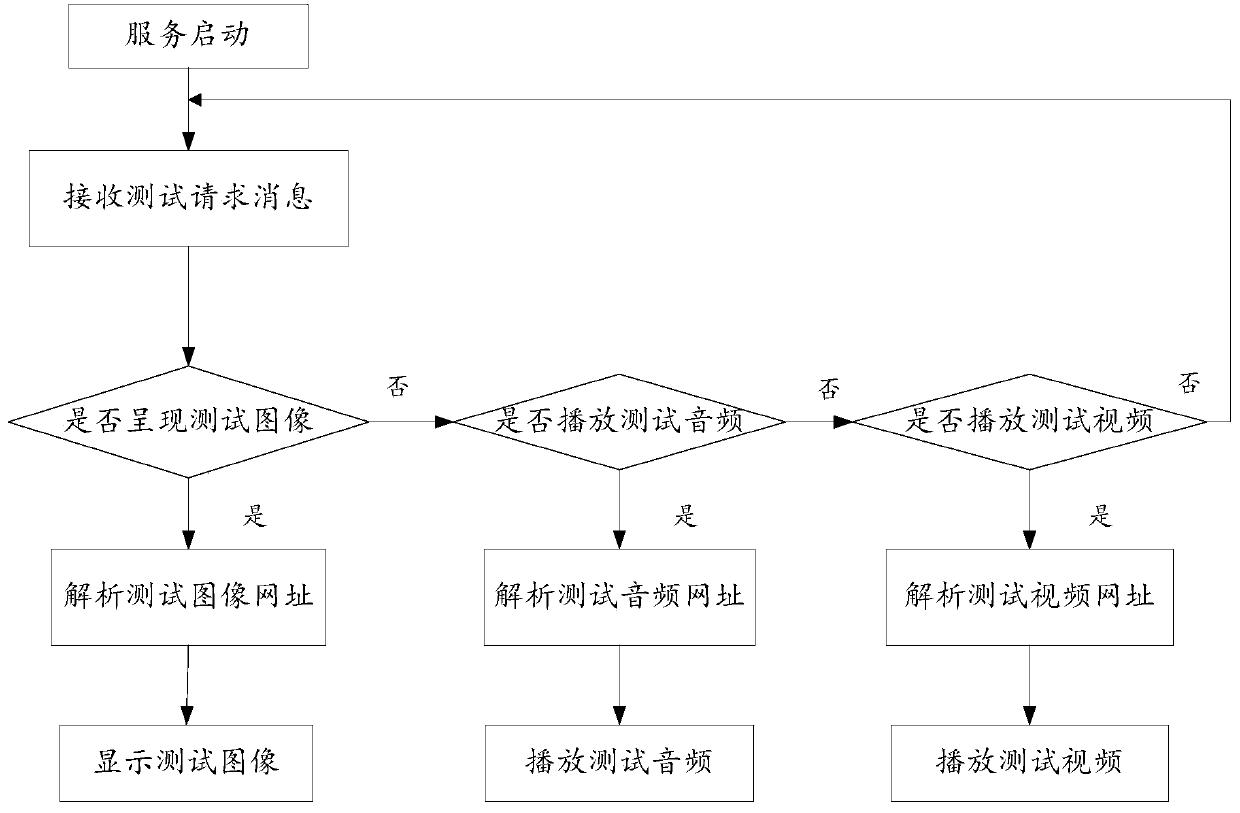

Automatic test system and method for intelligent display terminal, and storage medium

PendingCN110532141AImprove test efficiencyImprove accuracyDetecting faulty hardware by remote testSoftware testing/debuggingComputer hardwareTest efficiency

The invention relates to an automatic test system and an automatic test method for an intelligent display terminal and a storage medium. The automatic test system comprises a cloud server, a test station and a to-be-tested intelligent display terminal, and the test station comprises a test terminal and a test assembly; the test terminal sends a test request message to the cloud server or receivesthe test request message sent by the cloud server, obtains a test case from the cloud server, tests the to-be-tested intelligent display terminal by controlling the test assembly according to the testcase, and sends the obtained test information to the cloud server; and the cloud server receives the test request message sent by the test terminal or sends the test request message to the test terminal, determines a corresponding test case according to the test request message, and is also used for intelligently analyzing the received test information and / or test request message and generating atest report. According to the invention, the intelligent display terminal can be automatically tested, the test efficiency can be improved, the human input is reduced, and the product quality is improved.

Owner:峰米(北京)科技有限公司

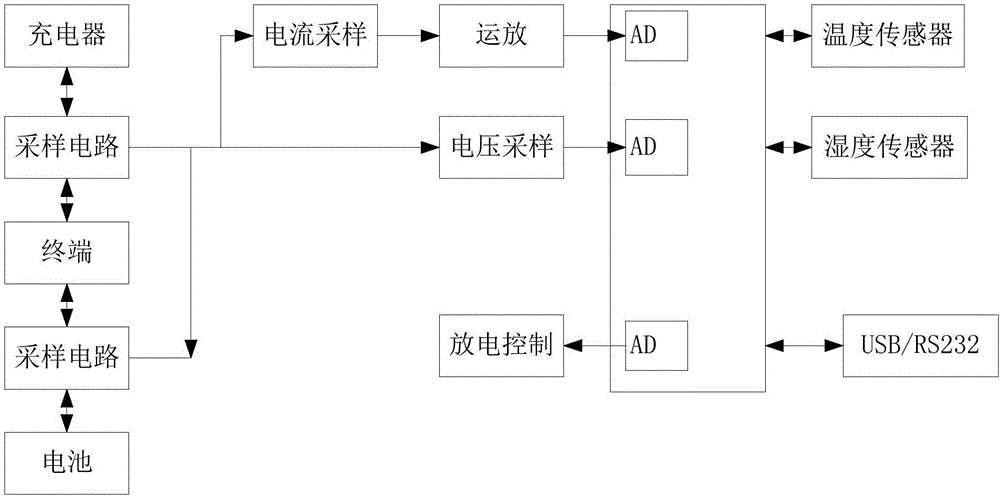

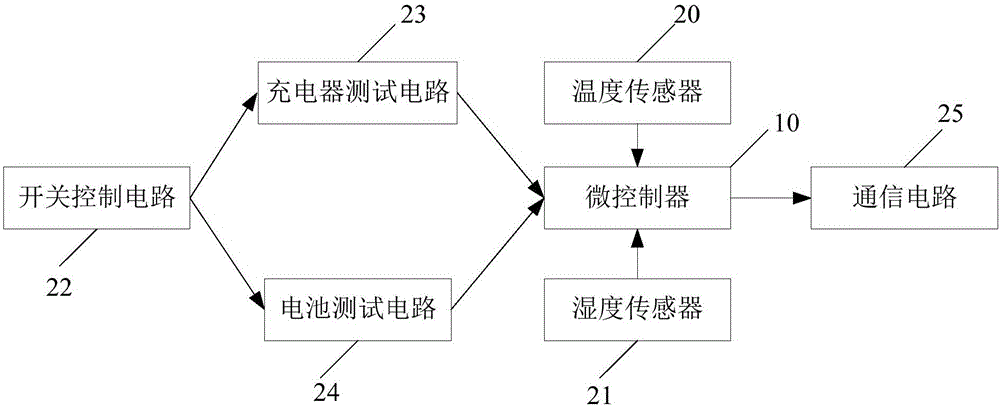

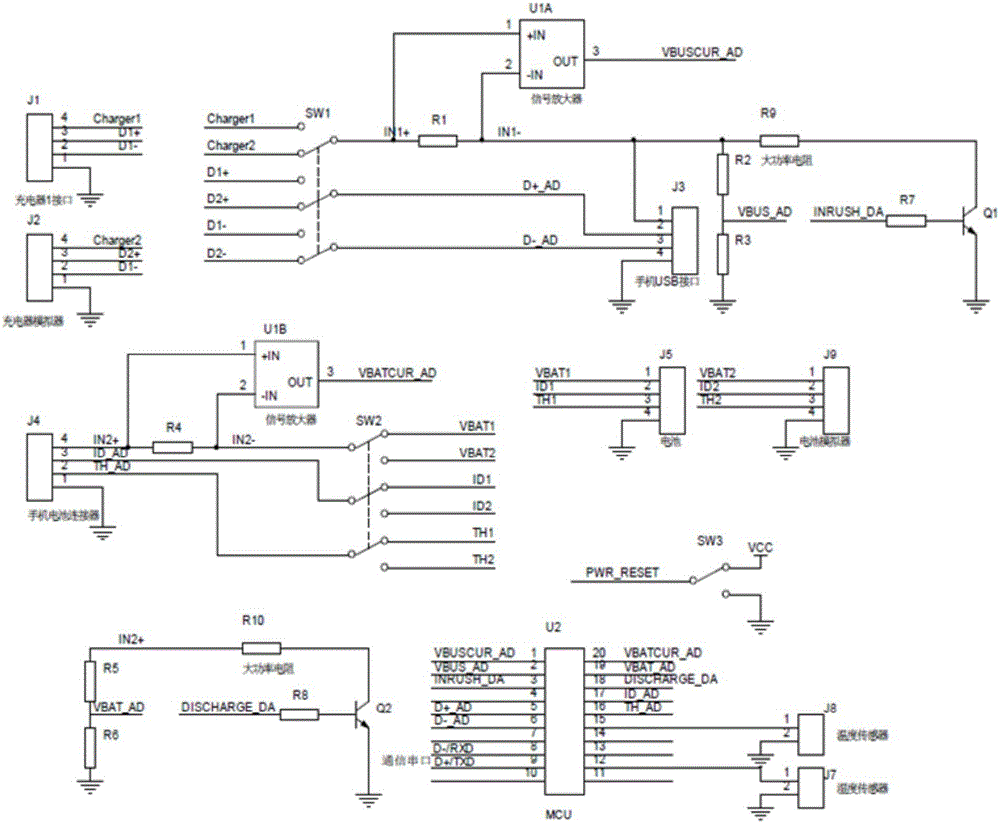

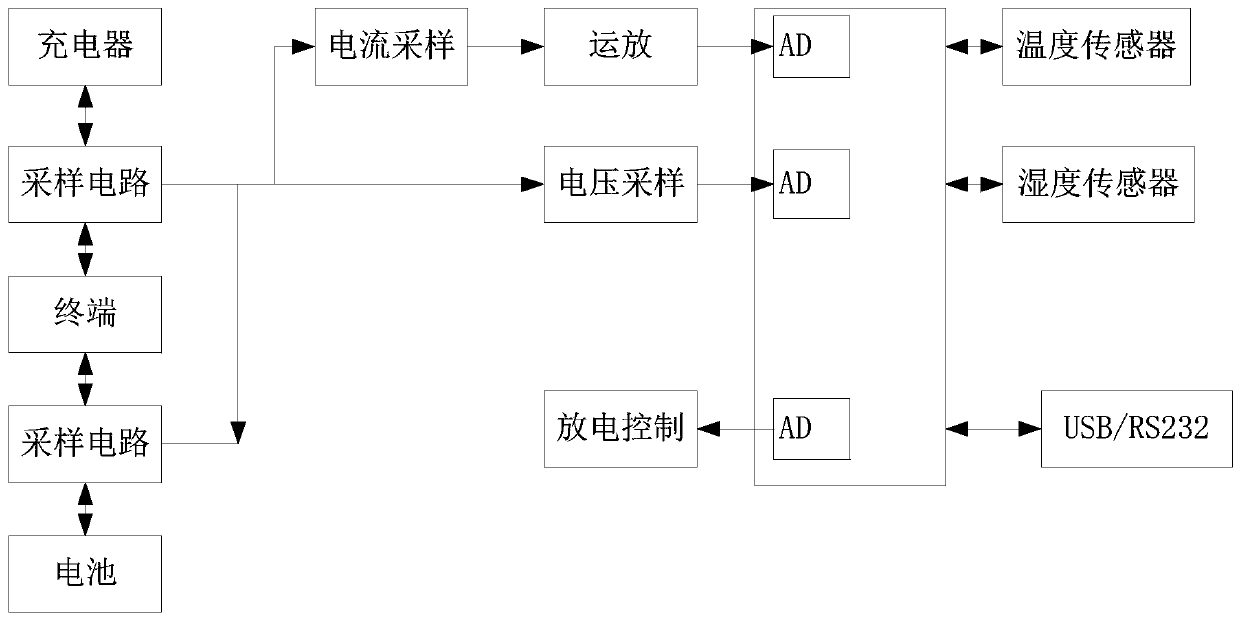

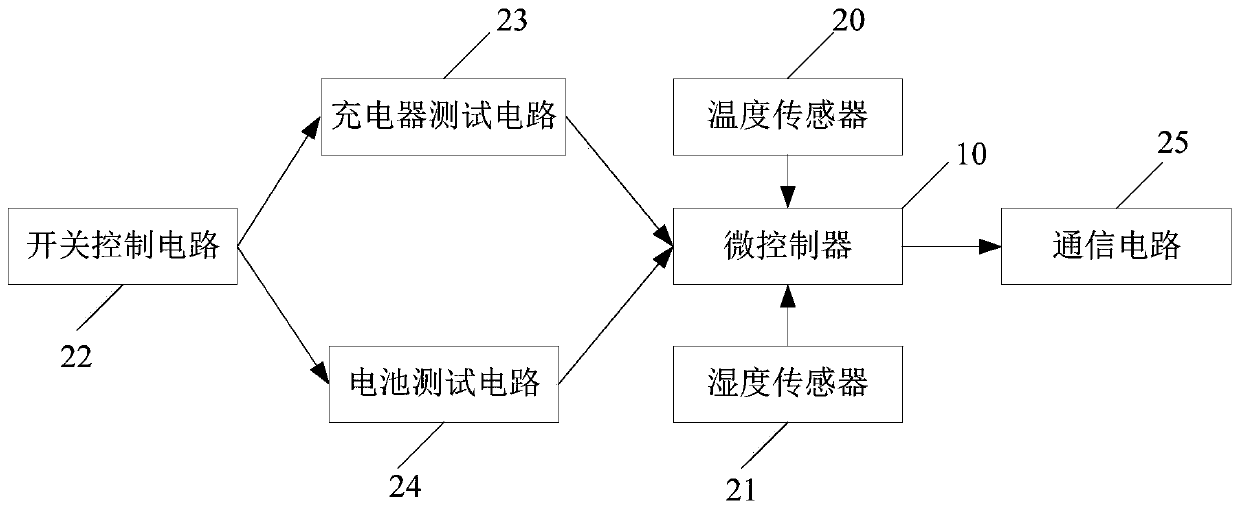

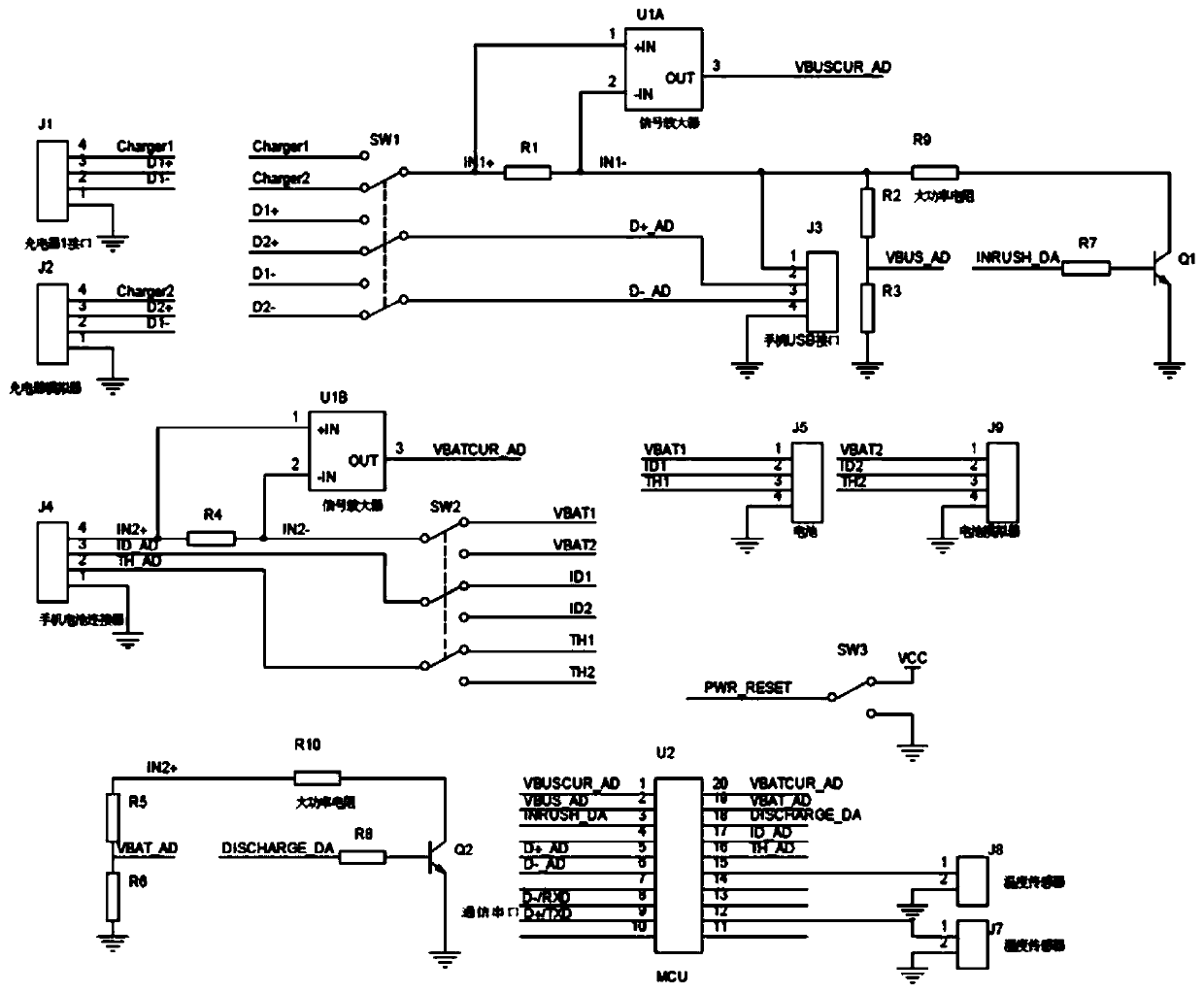

Automatic terminal charging/discharging test circuit and automatic terminal charging/discharging test method

ActiveCN106291179ARealize fully automated testingSave time and costElectrical testingMicrocontrollerTest efficiency

The invention discloses an automatic terminal charging / discharging test circuit, comprising a microcontroller and a peripheral circuit, wherein the peripheral circuit comprises an environmental sensor, a switch control circuit, a charger test circuit, a battery test circuit and a communication circuit, wherein the environmental sensor is connected with the microcontroller, and is used to detect environmental information, the switch control circuit is used to enable a terminal to select to test a battery and a charger in an on / off state, the charger test circuit is connected with the switch control circuit and the microcontroller, and is used to detect target parameters of the charger, the battery test circuit is connected with the switch control circuit and the microcontroller, and is used to detect the target parameter of the battery, and the communication circuit is connected with the microcontroller, and is used to send the environmental information and the target parameters to a processor. According to embodiments of the invention, operations such as startup, shutdown, charger replacement and the like in the test process are realized through the switch control circuit, so that full-automatic charging / discharging test is realized, labor cost and time cost are saved, and test efficiency is increased. The invention also discloses a test method.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

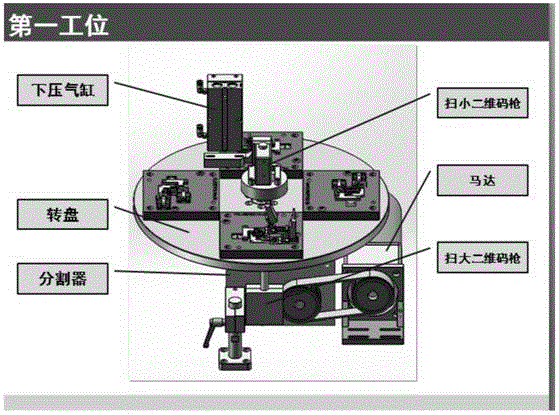

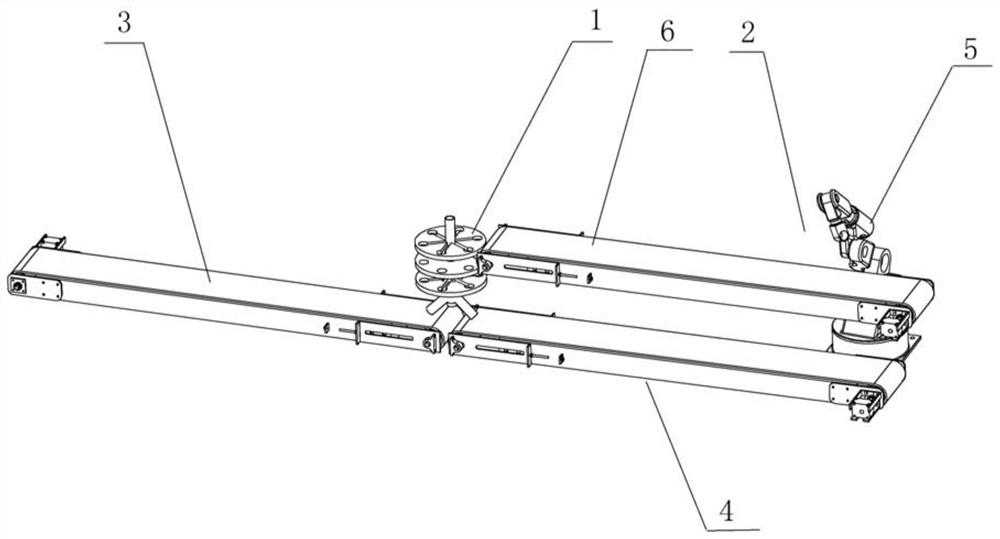

Turntable automatic testing device and method

InactiveCN105334447ARealize intelligenceFully automatedElectronic circuit testingMotor driveTest sample

The invention discloses a turntable automatic testing device and method. The device comprises a motor, a turntable, and a bar code scanning gun. The motor drives the turntable to rotate. The turntable is equipped with at least four operating positions including an ICT testing position, a tone leakage testing position, a sensitivity testing position, and a discharging position which are used for testing an ICT, testing tone leakage, testing sensitivity, and discharging materials respectively. The bar code scanning gun is arranged on the center of the turntable in order to scan a bar code on the corresponding operating position. The device and the method may achieve full-automatic testing. From loading to testing, a tester is just required to place a test sample in a SOCKET and following testing is basically intellectualized and automated. In addition, the device and the method may achieve parallel testing and prevent parallel testing incapability caused by the characteristic of the test sample.

Owner:CHIPSEA TECH SHENZHEN CO LTD

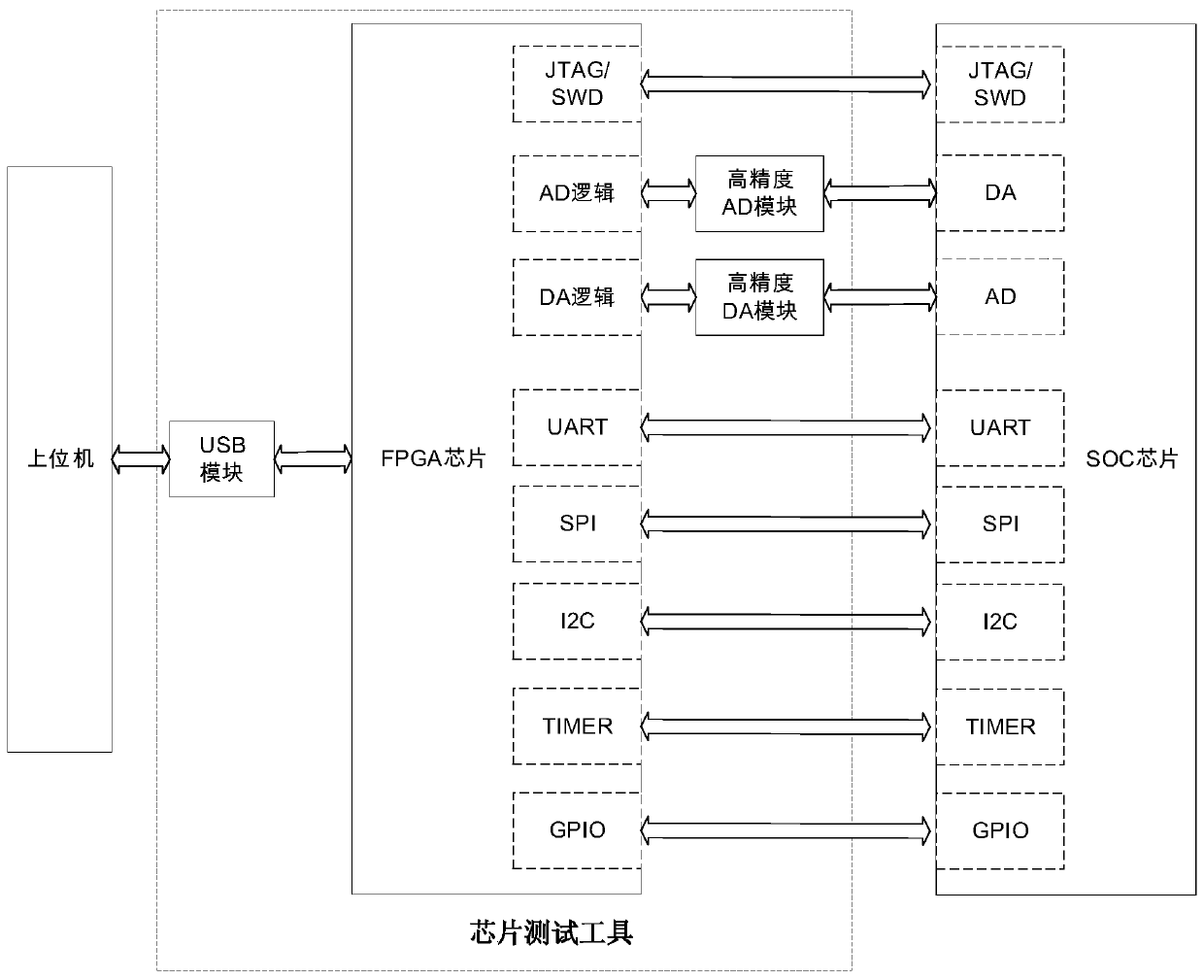

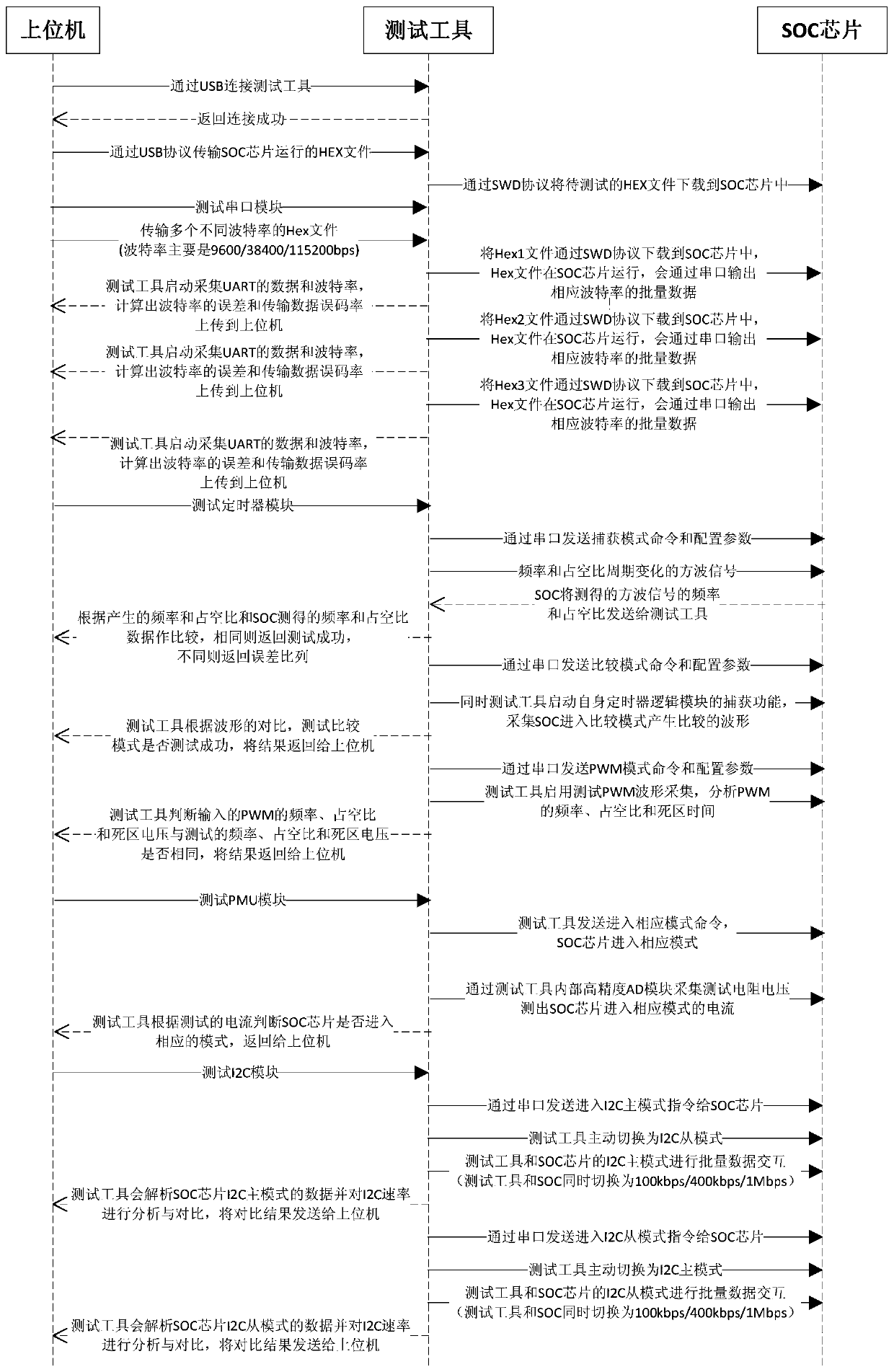

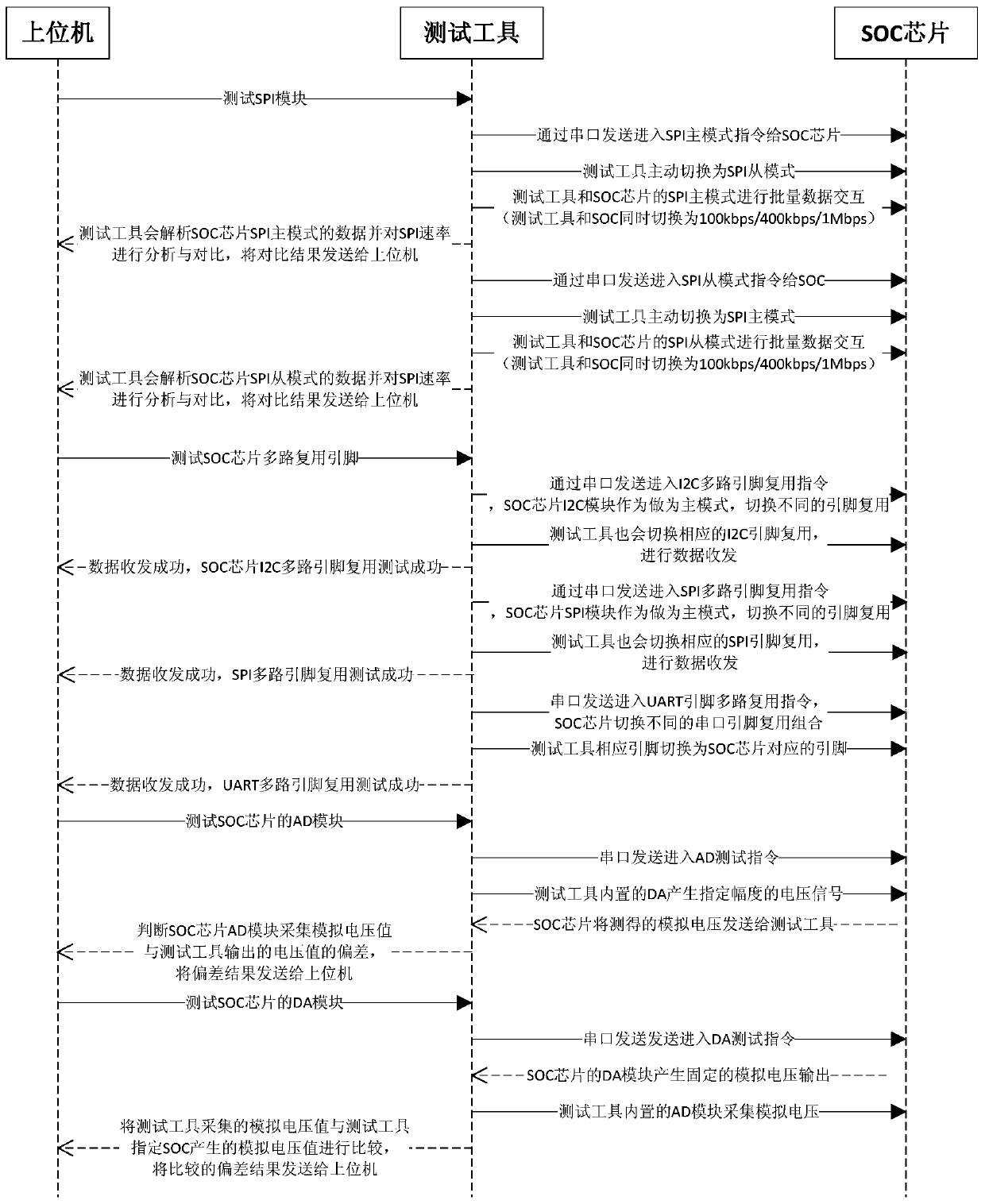

FPGA-based SOC chip automatic test tool and test method

InactiveCN111025129ARealize fully automated testingImplement automated testingElectronic circuit testingComputer architectureFpga chip

The invention provides an SOC chip automatic test tool based on an FPGA. The SOC chip automatic test tool comprises an upper computer interface module, an FPGA chip, a high-precision AD module and a high-precision DA module which are connected, wherein the upper computer interface module is used for being connected with an upper computer, the FPGA chip is provided with a JTAG / SWD logic module usedfor being in butt joint with a JTAG / SWD module on the SOC chip, an AD logic module used for controlling the high-precision AD module to be in butt joint with the DA module on the SOC chip, the DA logic module used for controlling the high-precision DA module to be in butt joint with the AD module on the SOC chip, an UART logic serial port module used for being in butt joint with a UART serial port module on the SOC chip, an SPI logic module used for being in butt joint with an SPI module on the SOC chip, an I2C logic module used for being in butt joint with an I2C module on the SOC chip, a timer logic module used for verifying a timer on the SOC chip, and a GPIO logic module used for being in butt joint with a GPIO module on the SOC chip. The test tool is advantaged in that full automation of the test process is realized.

Owner:中电海康无锡科技有限公司

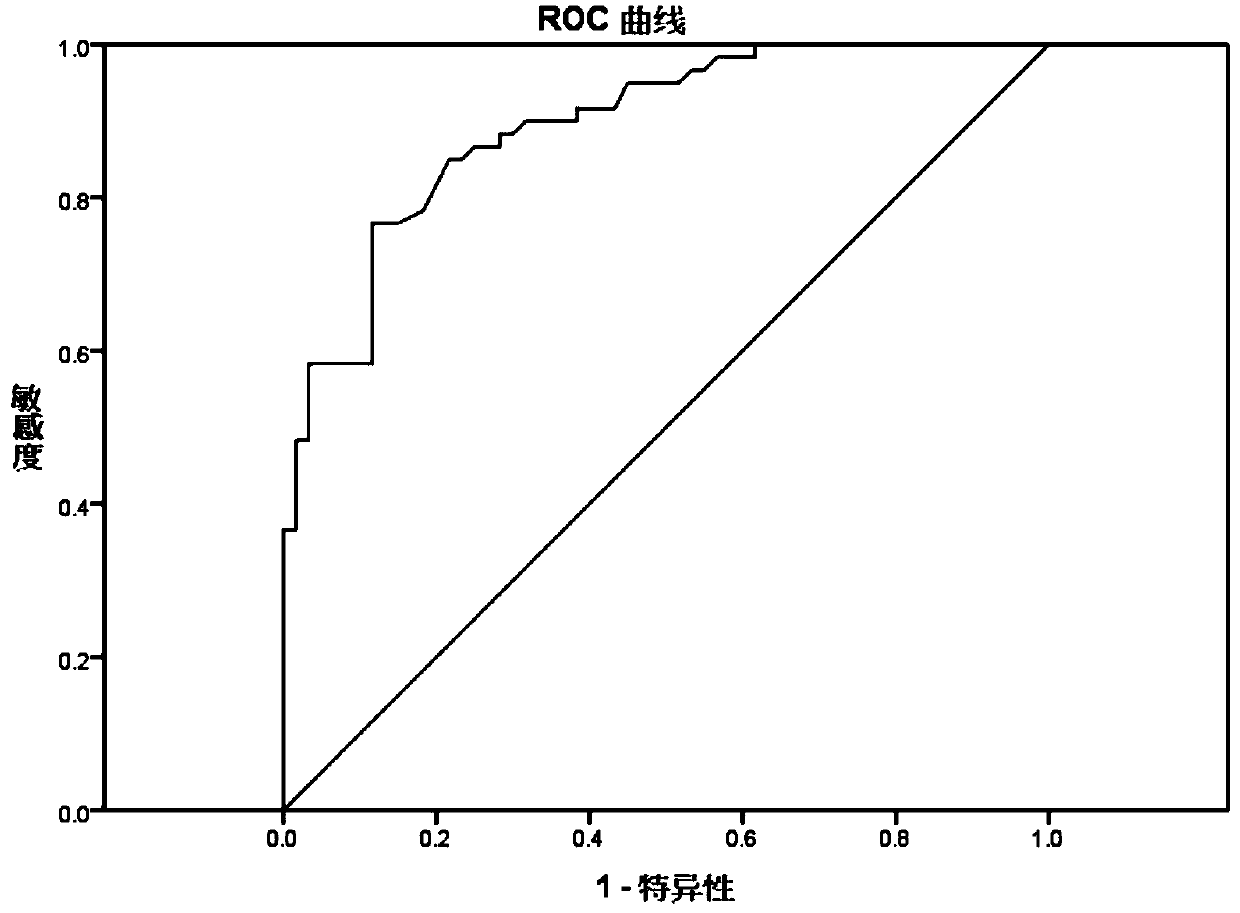

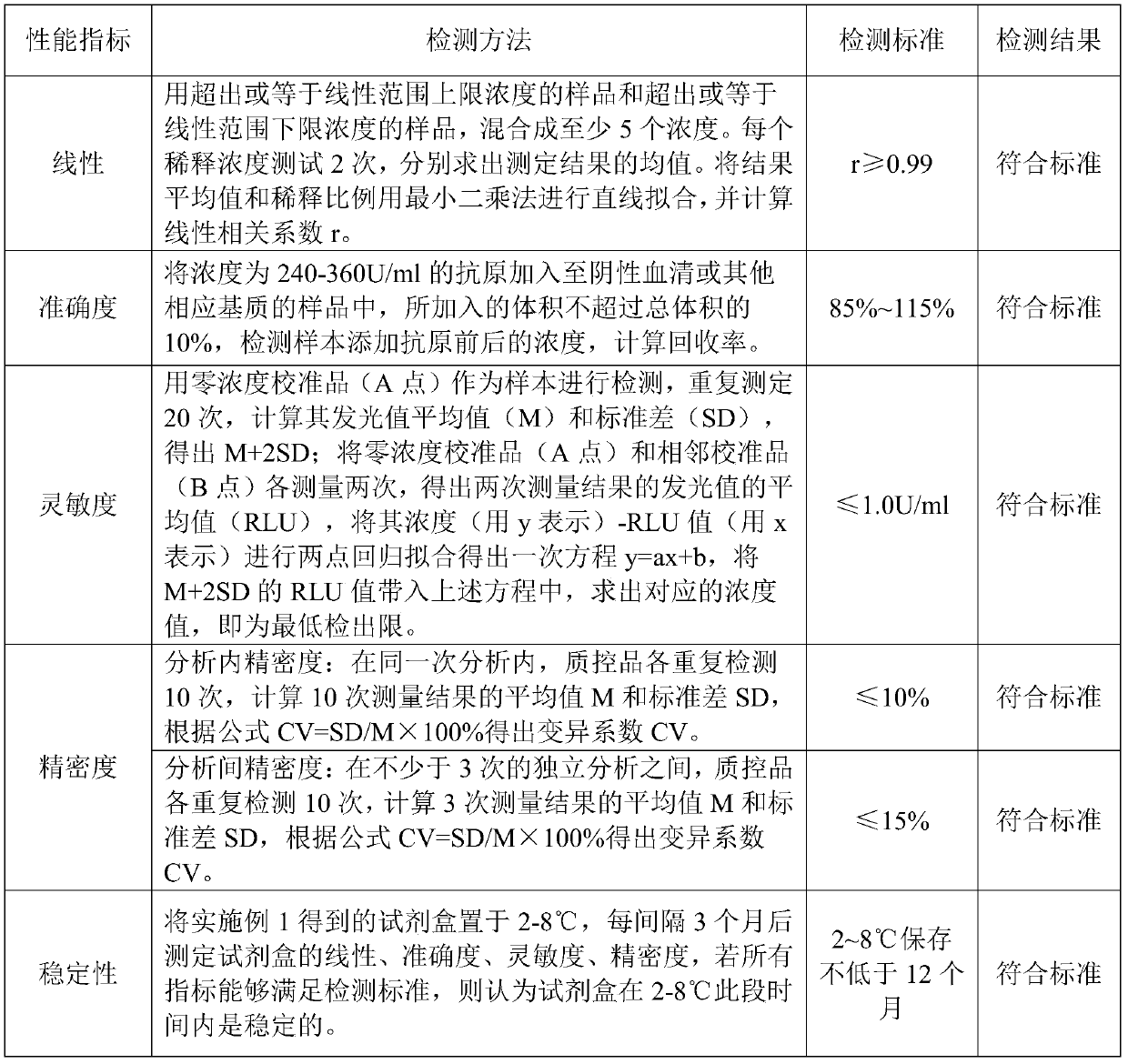

Kit for preparing CA125 surface Tn antigen by magnetic particle chemiluminescence immunoassay and preparation method thereof

ActiveCN109781986ARemarkable substrate specificityEasy to identifyChemiluminescene/bioluminescenceFermentationBiotin-streptavidin complexAntigen

The invention relates to the technical field of immunoassay, in particular to a kit for preparing a CA125 surface Tn antigen by magnetic particle chemiluminescence immunoassay and a preparation methodthereof. The kit comprises a magnetic separation reagent coupled with a Fab fragment of a CA125 antibody, a biotin-lectin reagent, and a streptavidin-biotin-alkaline phosphatase coupling reagent, wherein the biotin-lectin reagent containing sialidase is capable of identifying the Tn antigen. The magnetic separation reagent is specifically bound to the CA125 antigen; the biotin-lectin specificallyrecognizes the Tn antigen of the CA125 antigen surface; the streptavidin-biotin-alkaline phosphatase coupling reagent is specifically bound to the biotin-lectin reagent to realize amplification of the detection signal; the sialidase hydrolyzes a glucosidic bond connected with the sialic acid on the Tn antigen surface and the sialic acid is released to expose the Tn antigen. Therefore, the detection accuracy, sensitivity and linear range are improved. The kit has advantages of high specificity and high sensitivity and is capable of realizing fully automated testing.

Owner:THE OBSTETRICS & GYNECOLOGY HOSPITAL OF FUDAN UNIV

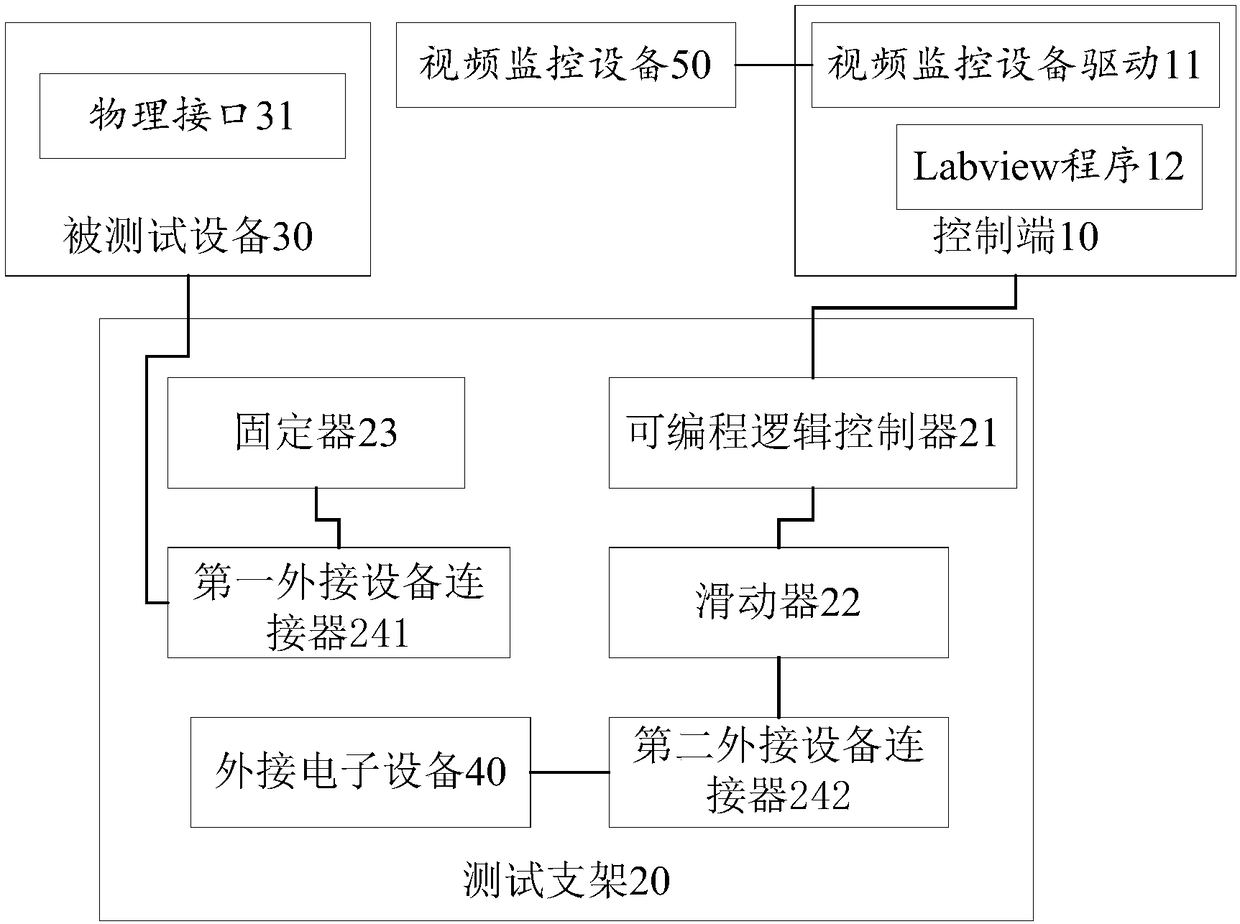

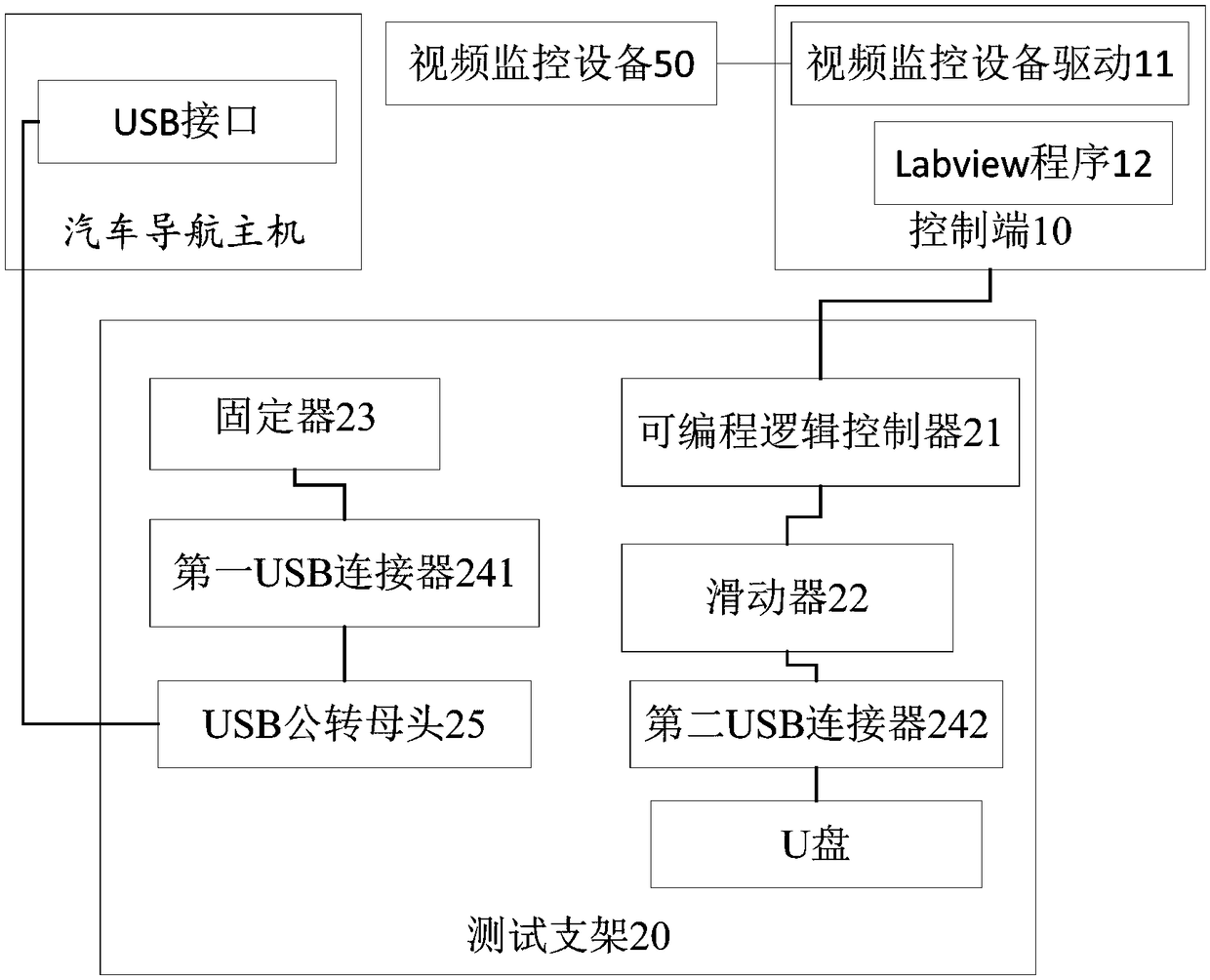

Fully automated test system for hot plugging of external devices

InactiveCN108280000AQuick judgmentAccurate judgmentFaulty hardware testing methodsComputer hardwareVideo recording

The invention relates to the field of automated testing, and discloses a fully automated test system for hot plugging of external devices. The system comprises a video monitoring device, a control end, a testing supporting frame and a to-be-tested device which are sequentially connected, wherein the to-be-tested device is provided with a display interface for displaying the inserting and pulling states of the to-be-tested device when the to-be-tested device is connected with the external electronic devices; the video monitoring device is used for monitoring the display interface of the to-be-tested device in real time; a video monitoring device drive is installed on the control end, and video recording parameters of the video monitoring device are adjusted and a photographing state is controlled through the control end to perform replaying of recorded videos and photographed images; the external electronic devices are fixed on the testing supporting frame, and the testing supporting frame is used for simulating the hot plugging between the external electronic devices and the to-be-tested device; the control end is used for transmitting testing parameters and operational instructions to the testing supporting frame and displaying testing results. By means of the system, the testing efficiency and accuracy are improved, and the cost is reduced.

Owner:HUIZHOU DESAY SV AUTOMOTIVE

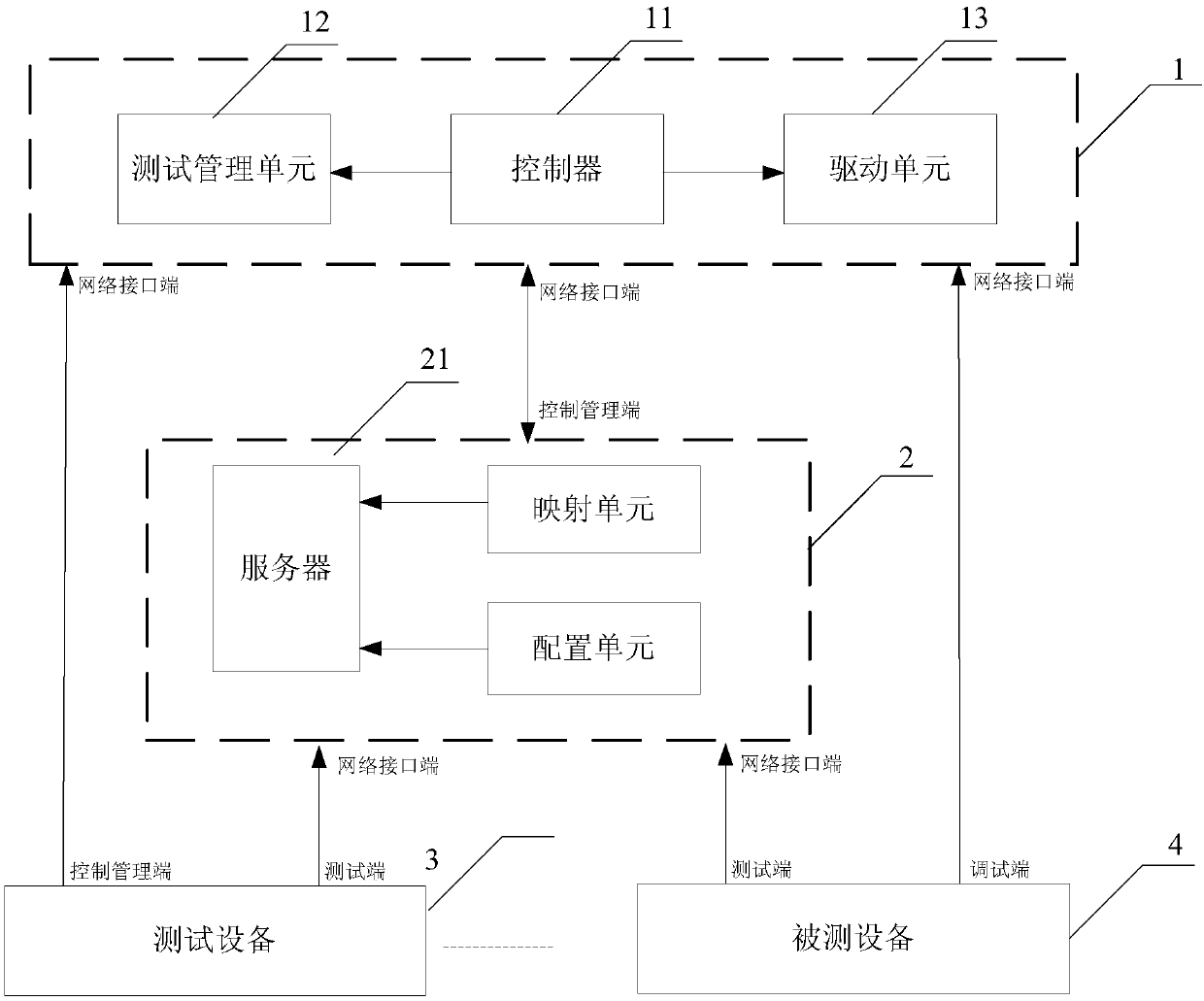

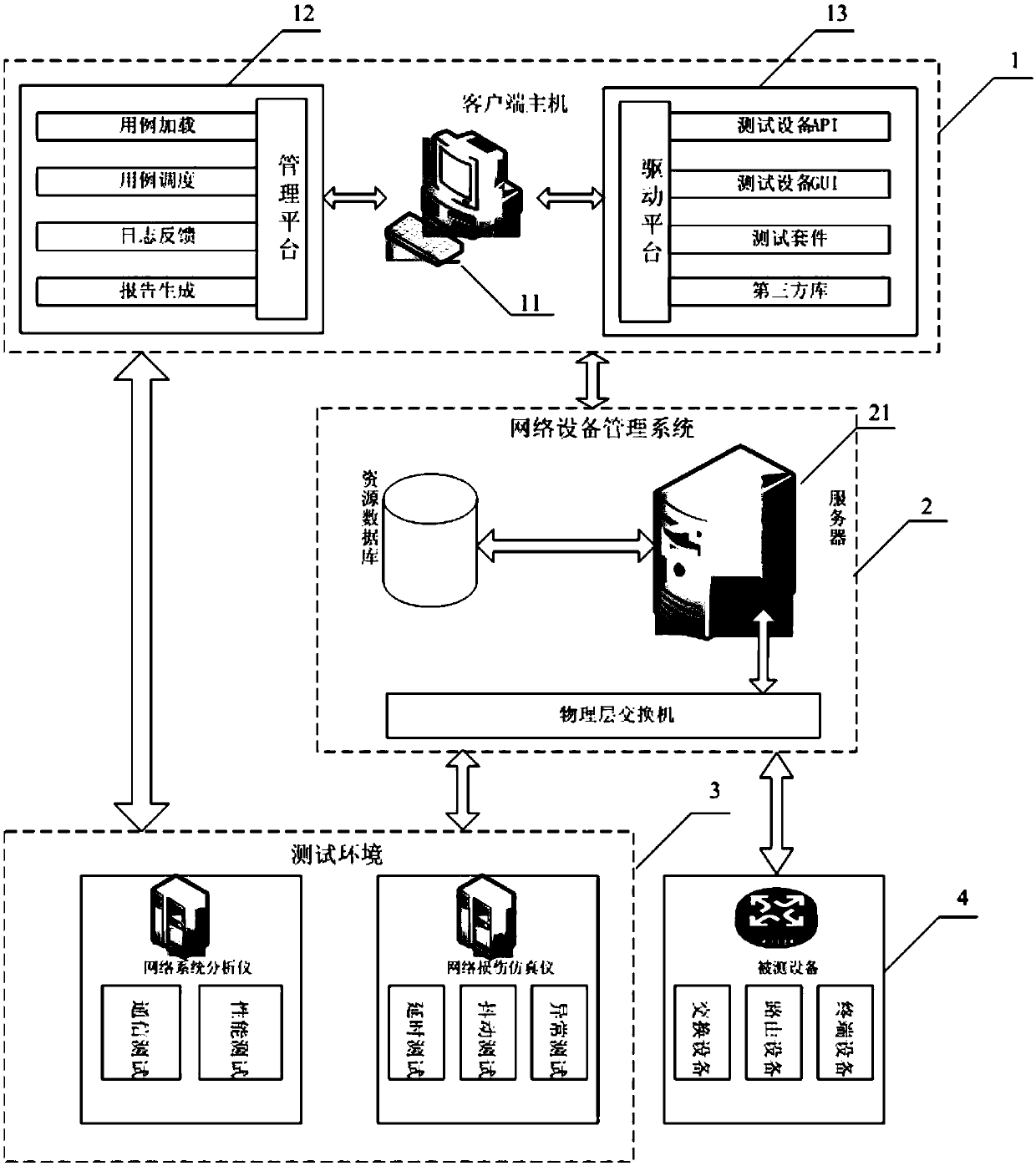

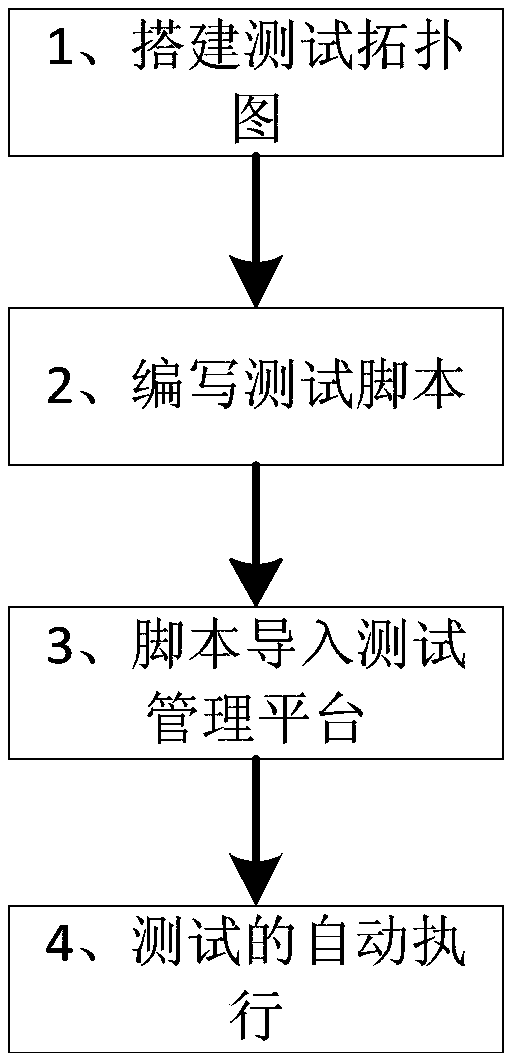

Automatic test system and method for switching equipment in rail transit system

PendingCN111294225ARealize fully automated testingImprove test efficiencyData switching networksAccess networkTest efficiency

The invention discloses an automatic test system and method for switching equipment in a rail transit system. The system comprises a test control module used for performing test control, an equipmentmanagement module used for managing accessed network device and more than one piece of test equipment used for executing tests. The test control module is connected with the test ends of the test equipment and the tested equipment through the equipment management module. The debugging end of the tested equipment is connected with the test control module, and the test control module configures thetest equipment and the connection between the tested equipment through the equipment management module so as to carry out required network topology configuration and controls the test equipment to test the tested equipment according to a required test task. The method can achieve the automatic testing of the switching equipment in the rail transit system, and has advantages of wide testing range,high testing efficiency and testing precision, and facilitating the implementation of complex topology testing and case reproduction.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

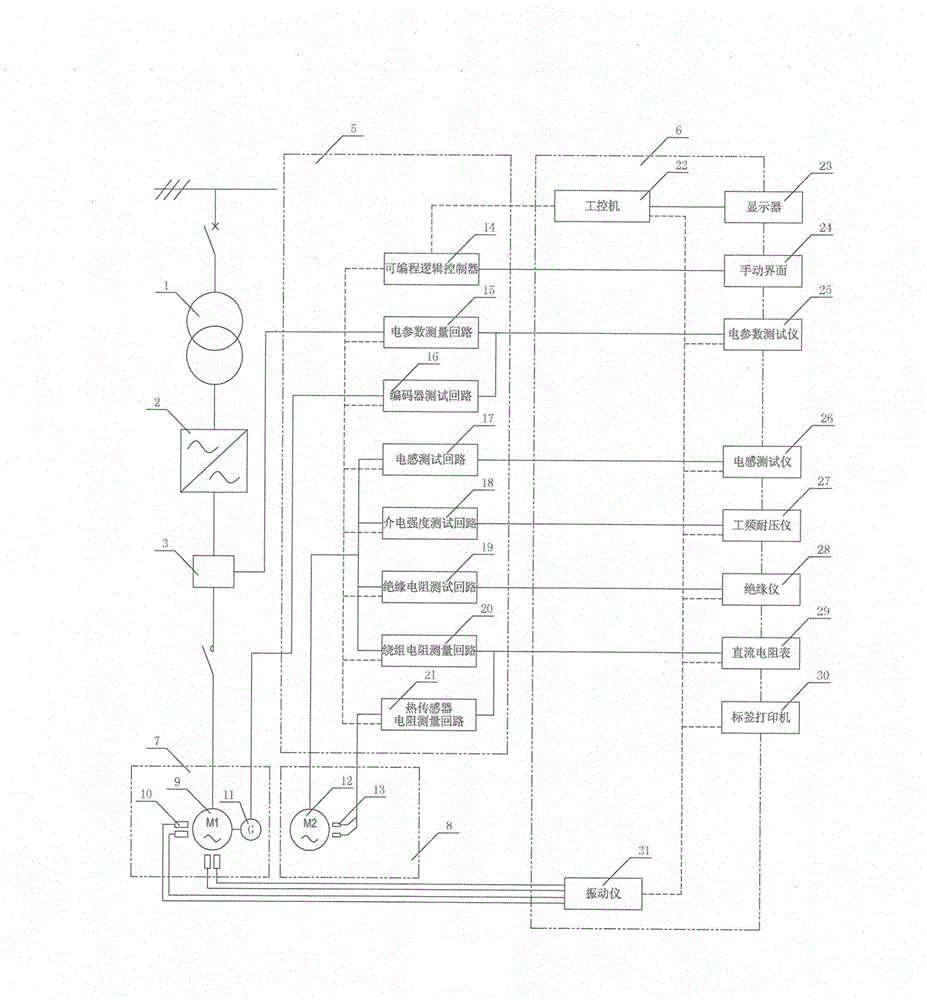

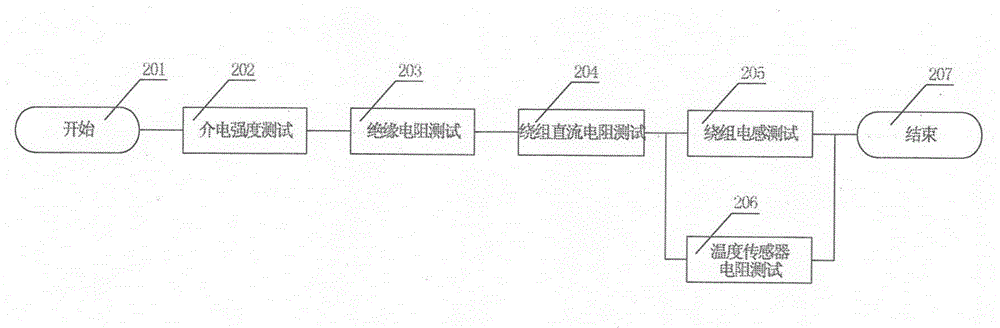

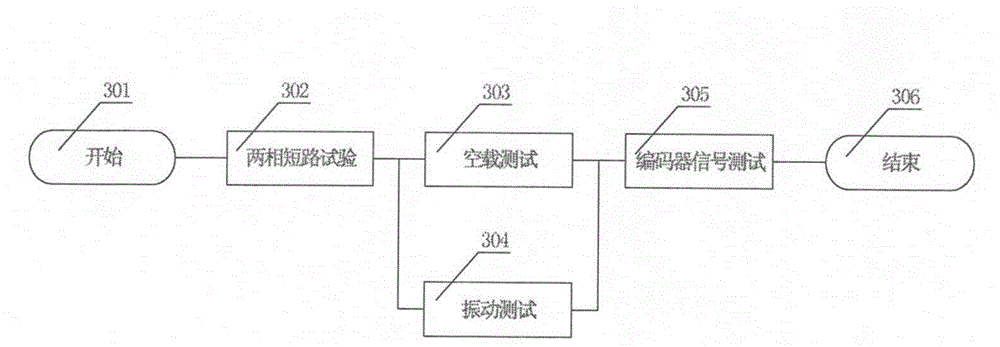

Fully automatic automobile motor delivery test measurement and control system

InactiveCN104678299ARealize fully automated testingImprove reliabilityDynamo-electric machine testingTest powerMeasuring instrument

The invention relates to a fully automatic automobile motor delivery test measurement and control system, which comprises parts including a test power supply, a measuring system, a control system, a test station, a measuring instrument, a label printer, a tested motor and the like. The system has the following characteristics that the test is divided into two parts including a static test and a dynamic test, and the two parts of test are in simultaneous parallel operation in the two stations. The static test comprises dielectric strength test, insulation resistance test, winding direct current resistance test, winding inductance test and heat sensor test. The dynamic test comprises two-phase short circuit test, idle load test, coder signal detection and vibration test.

Owner:SHANGHAI MOTOR SYST ENERGY SAVING ENG TECH RES CENT +1

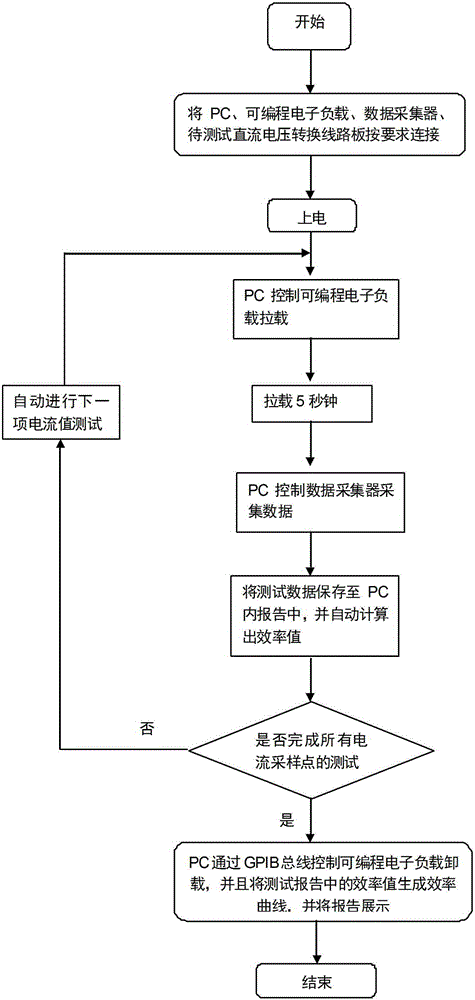

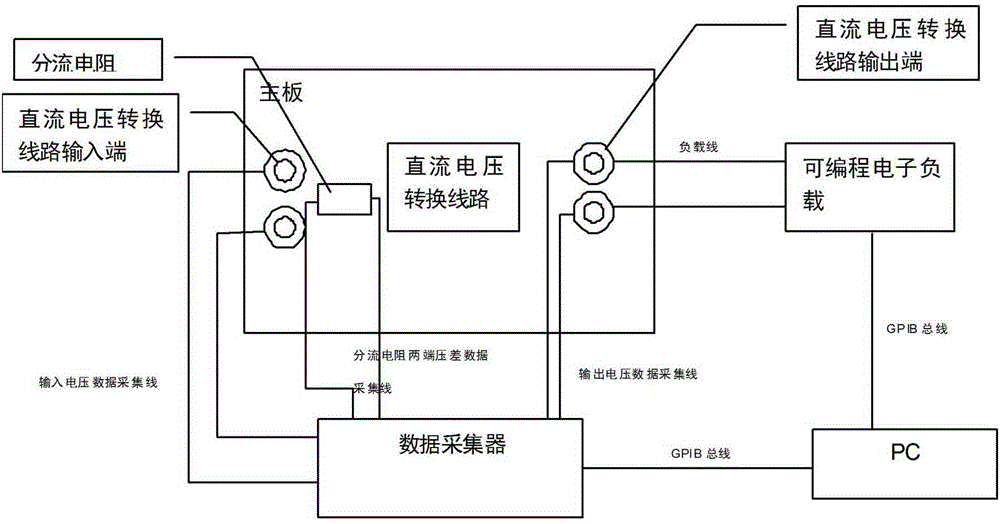

Method for automatically measuring DC voltage conversion efficiency

ActiveCN105242219AReduce staffing requirementsImprove test efficiencyPower supply testingData collectorElectronic load

The invention discloses a method for automatically measuring DC voltage conversion efficiency. The specific realization process is as follows: acquiring voltages of a DC voltage conversion circuit board through a data collector, then a personal computer (PC) controlling a programmable electronic load to automatically perform loading and unloading, controlling the data collector to automatically store data and feeding measuring data back to the PC timely through a GPIB bus, and after a test ends, automatically generating an efficiency curve in the PC. Compared to the prior art, the method for automatically measuring the DC voltage conversion efficiency can measure the DC voltage conversion efficiency more efficiently and accurately, simplifies the test process, improves the work efficiency and reduces the workload of test engineers. At the same time, the test precision is improved, and the test data is more accurate.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

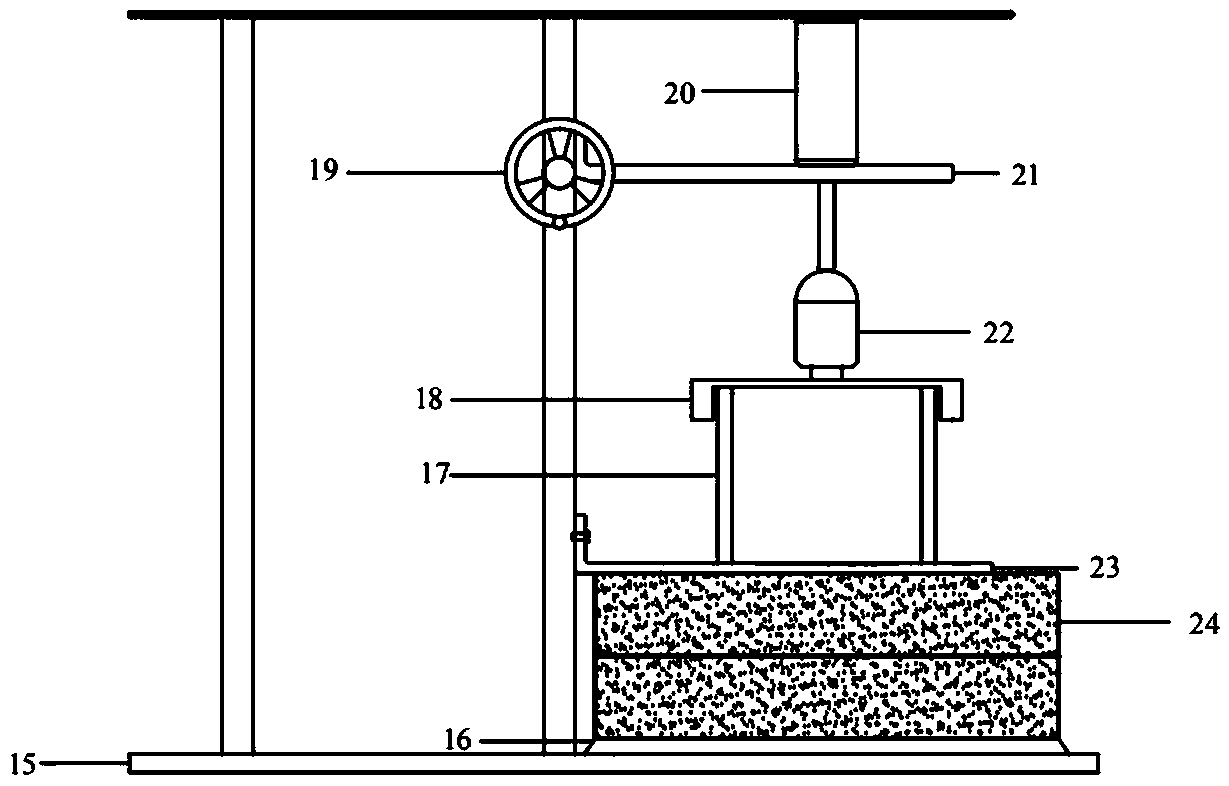

Aluminum alloy fluidity precise testing device and method

InactiveCN111122386AReduce mistakesPrecise speed controlDirect flow property measurementTemperature controlMetallurgy

The invention provides an aluminum alloy metal fluidity precise testing device and an aluminum alloy metal fluidity precise testing method. The aluminum alloy metal fluidity precise testing device ismainly composed of an industrial control heating module, a temperature control module, an electric control module, a weight control module and a casting mold module; and three important parameters ofpouring temperature, pouring speed and pouring weight are precisely controlled to realize precise measurement of metal fluidity. The test method selected for the test is a built-in three-spiral test method. Through automatically designing the metal fluidity full-automatic precise testing device and the metal fluidity full-automatic precise testing method, measuring the temperature by means of a thermocouple and transmitting molten aluminum temperature signals by means of a bus type temperature transmitter, precise control over the temperature of molten aluminum alloy is achieved in the castingprocess; a molten aluminum overflow device and the weight of molten aluminum are dynamically monitored, so that the weight of the molten aluminum alloy is precisely controlled; and the temperature feedback module is connected with the electric control module, so that the flow velocity during each casting is kept consistent, and the casting speed of the molten aluminum alloy is precisely controlled in the casting process.

Owner:ZHONGBEI UNIV

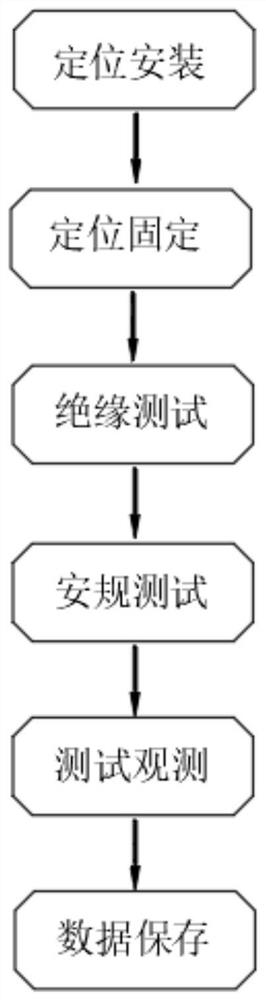

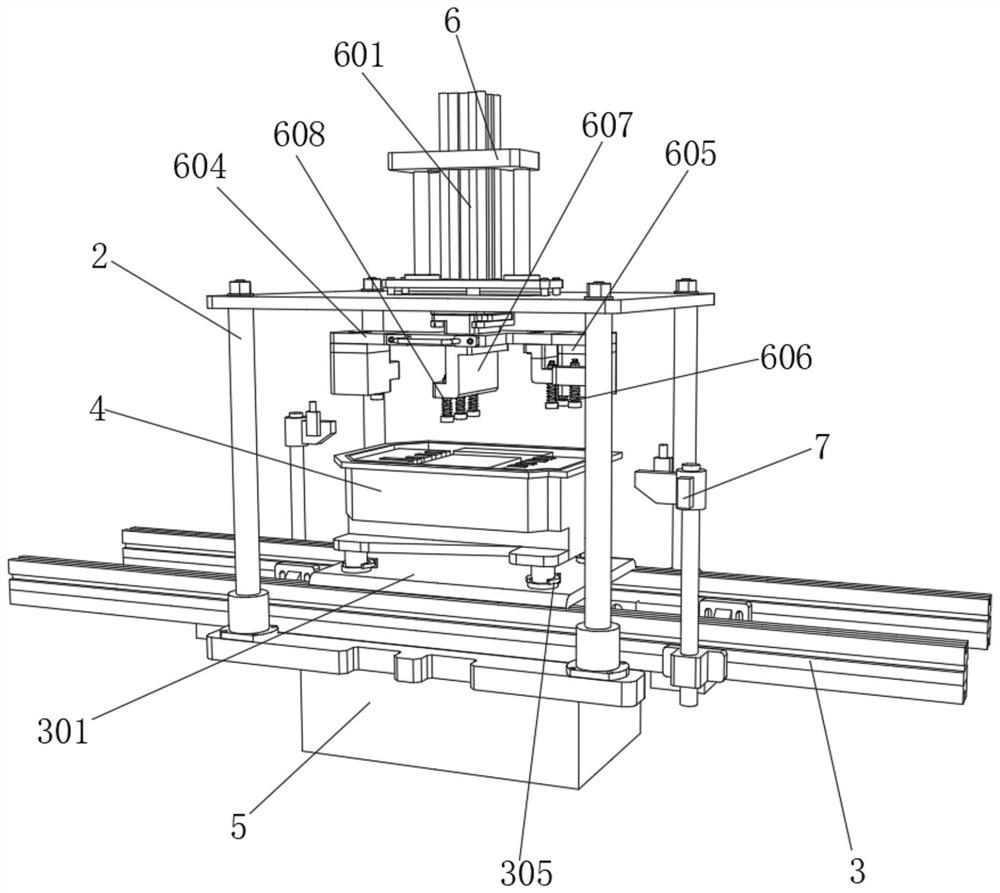

Automatic safety test device for new energy motor controller

PendingCN113866460AImprove test efficiency and stabilityImprove efficiencyShort-circuit testingMeasurement instrument housingElectric machineryAutomotive engineering

The invention relates to the technical field of safety test, and discloses an automatic safety test device for a new energy motor controller. The device comprises a pedestal, a to-be-detected controller sample, a product detection sensor, a warning lamp, a control system, a jacking mechanism, and a pressing test mechanism. The device uses an automatic safety test method for the new energy motor controller, and the method comprises the following steps of S1, positioning and mounting; S2, positioning and fixing; S3, carrying out an insulation test; S4, carrying out a safety test; S5, testing and observing; and S6, storing the data. According to the invention, the safety test and the full-automatic test of a new energy motor can be effectively realized, the test stability and the test efficiency are improved, the test efficiency is improved, the safety is realized, the automatic positioning and fixing can be realized, and the test stability is improved to a great extent.

Owner:山东众联能创动力科技有限公司

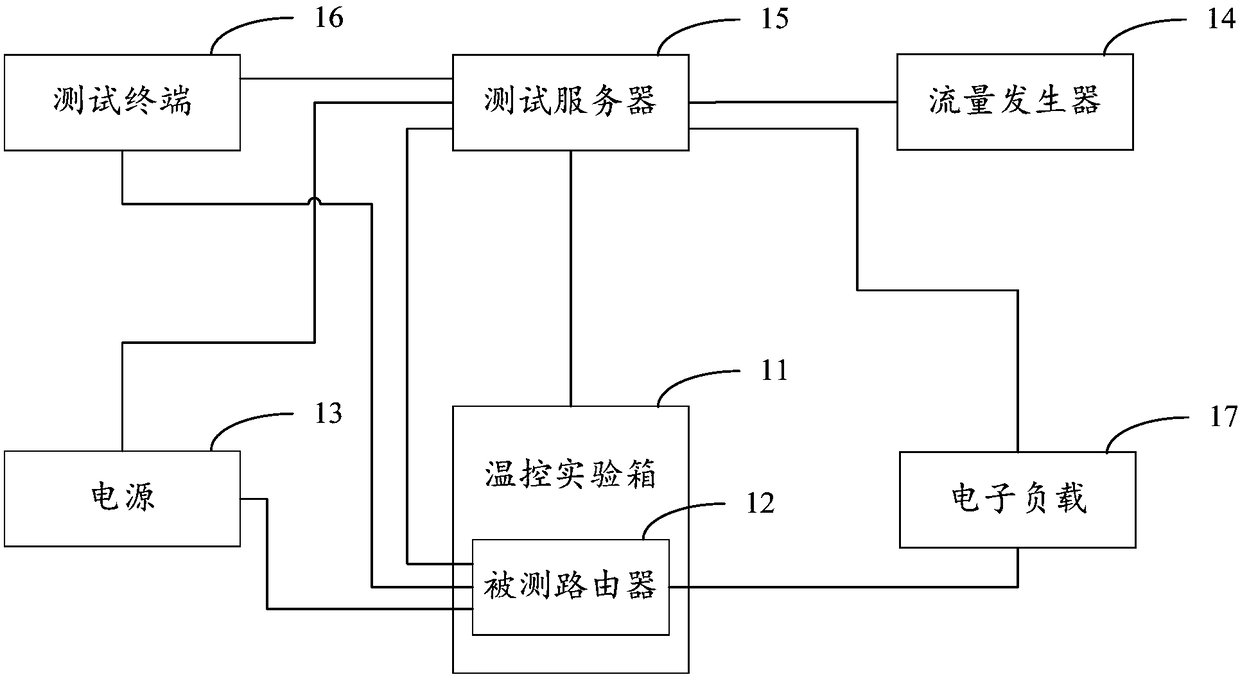

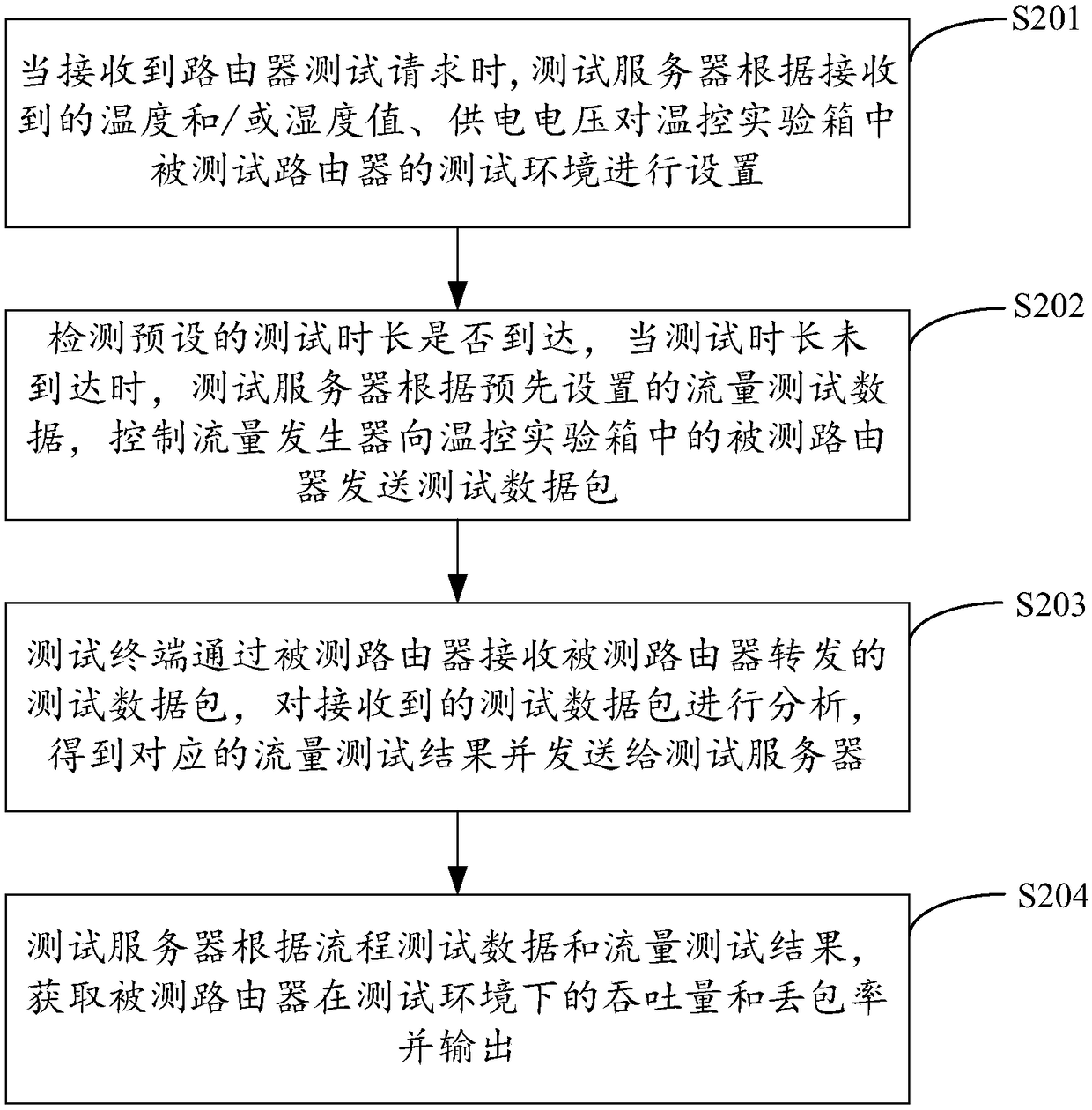

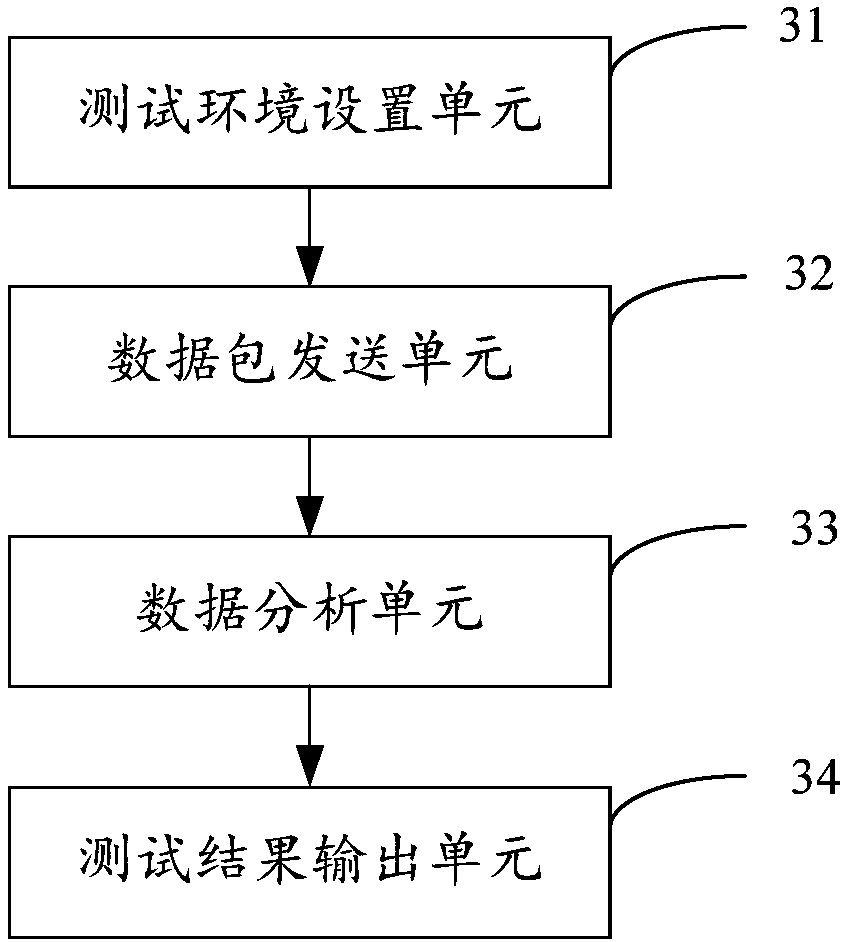

Test system, method and device used for router testing

InactiveCN108199957ARealize fully automated testingImprove test efficiencyMeasurement devicesData switching networksTemperature controlTest efficiency

The invention is suitable for the communication technology field and provides a test system, a method and a device used for router testing. The system comprises a temperature control experiment box, atested router, a power supply, a flow generator, a test server and a test terminal, wherein the temperature control experiment box is used for simulating test environments possessing different temperatures and / or humidity; the tested router is located in the temperature control experiment box; the power supply is connected to the tested router in the temperature control experiment box and is usedfor providing power for the tested router; the flow generator is used for sending an Ethernet data flow to the tested router so that the tested router works under a full load state; the test server is connected to the temperature control experiment box, the tested router, the power supply and the flow generator; and the test terminal is connected to tested router and the test server so as to carry out service exchange with the test server, and then the configuration requirement of a test environment is reduced. The full automation testing of the router is realized and the test efficiency of the test system is increased.

Owner:SHENZHEN GONGJIN ELECTRONICS CO LTD

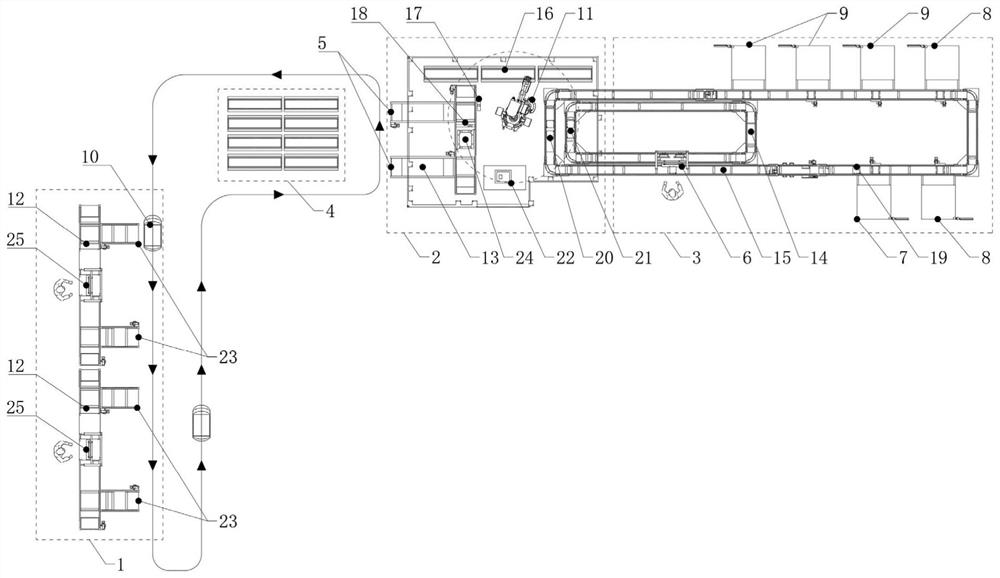

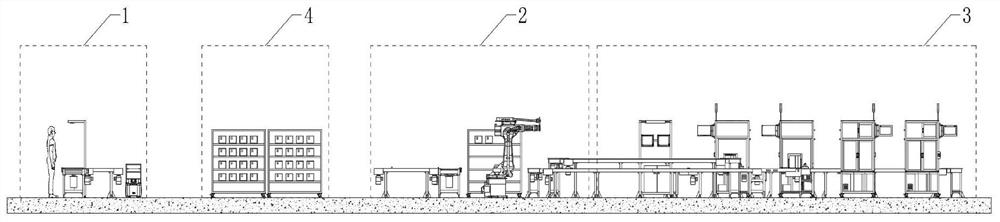

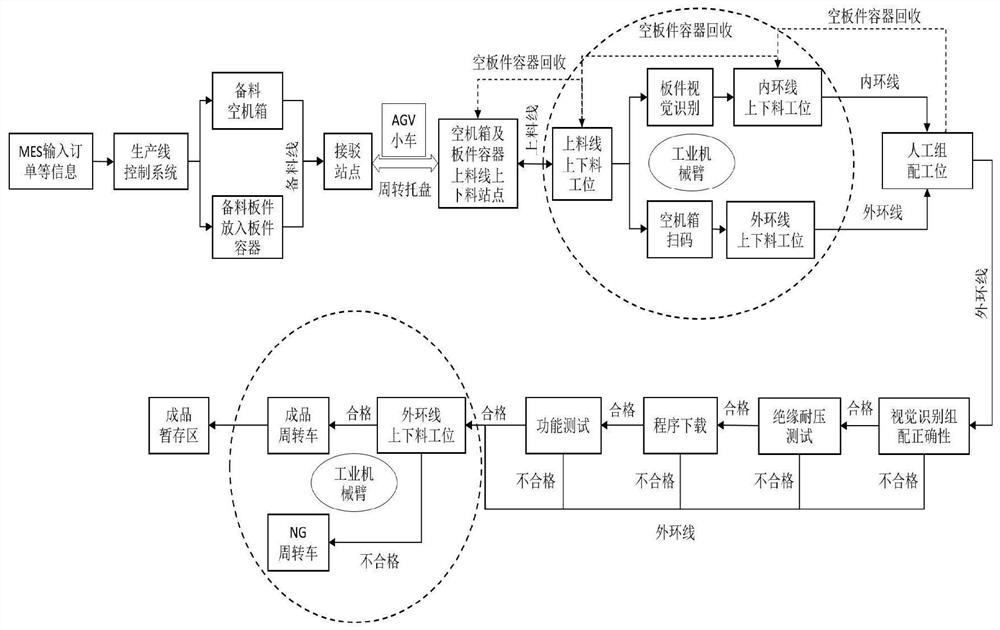

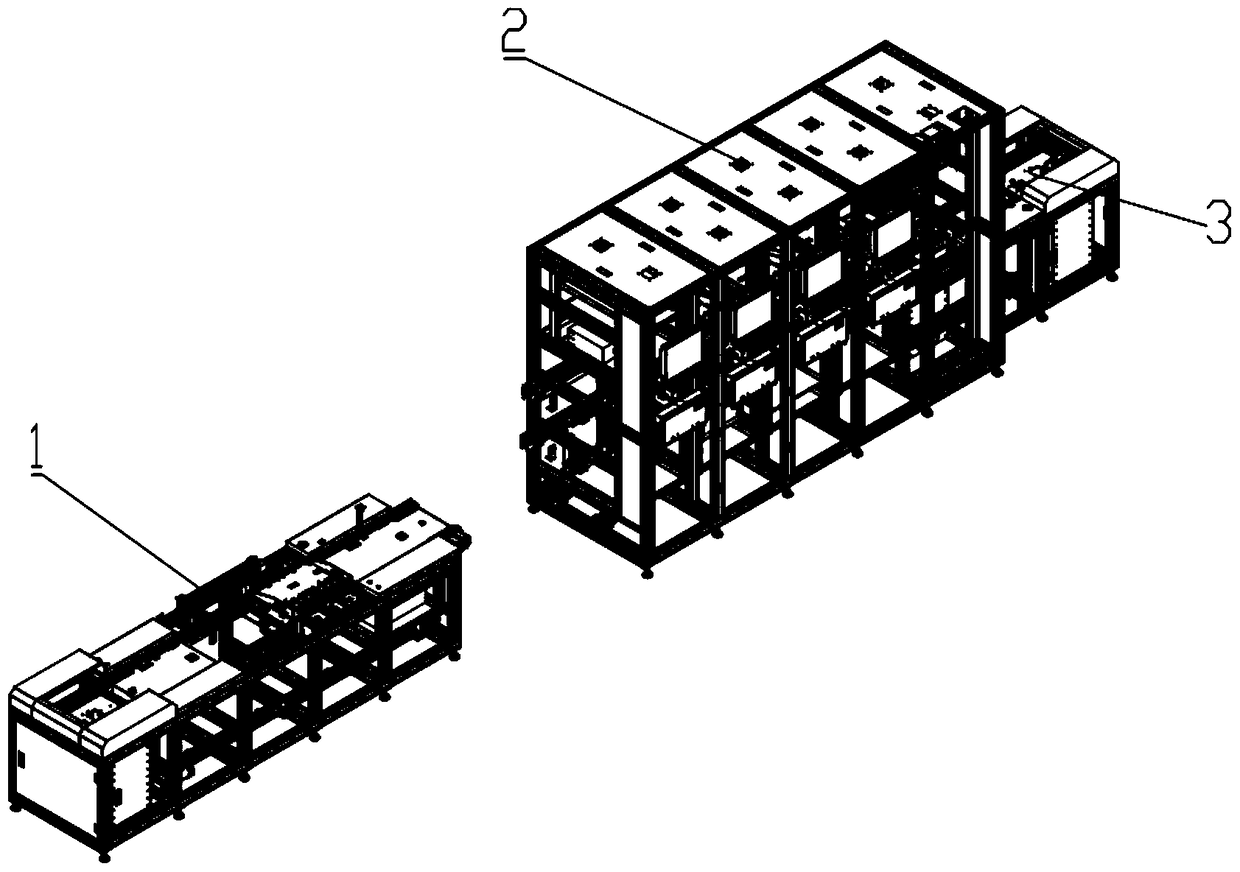

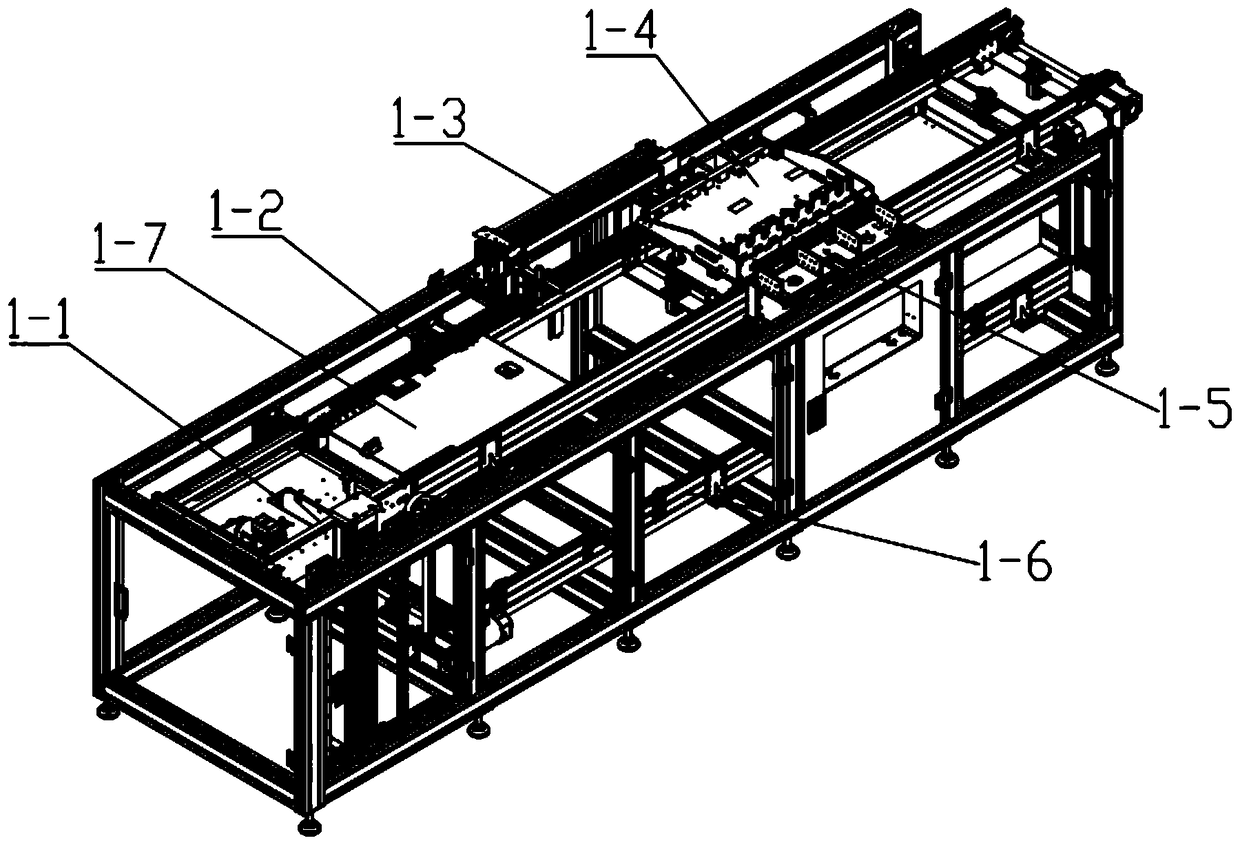

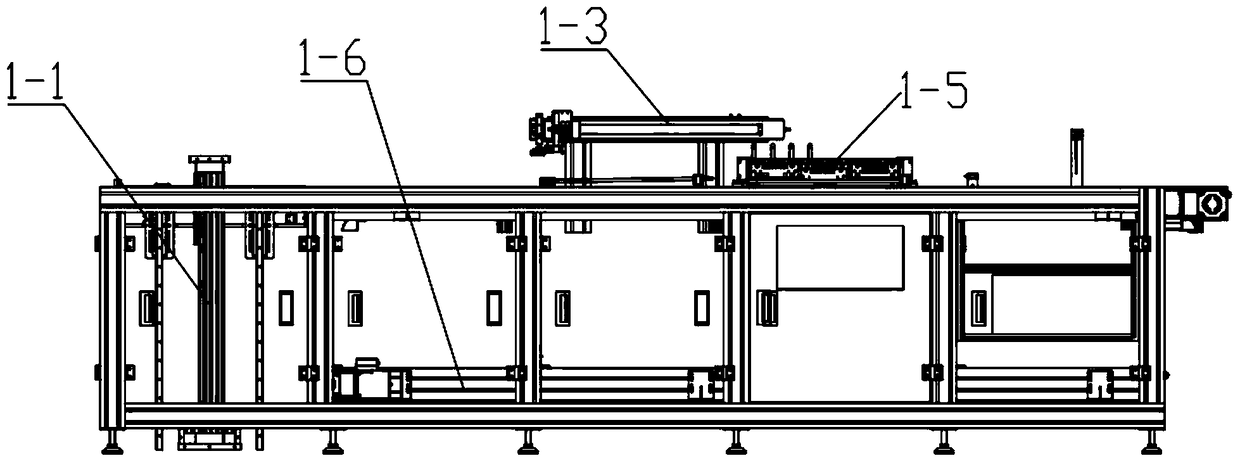

Intelligent production system and production method for power grid device

ActiveCN112904812AIncrease productivityPrevent manual misinstallationTotal factory controlProgramme total factory controlManufacturing execution systemPower grid

The invention discloses an intelligent production system for a power grid device. The intelligent production system comprises an operation area, a production line control system, a transport vehicle, an industrial mechanical arm, an automatic transmission line, device software downloading and testing equipment and a production line turnover container and the operation area comprises a raw material preparation area, a feeding and discharging area, a production area and a finished product temporary storage area. The production line control system performs information interaction with the manufacturing execution system and controls a production line; the transport vehicle is used for conveying an empty case and a plate container of the device; and the industrial mechanical arm completes carrying of the devices on the upper conveying line and the lower conveying line. The automatic transmission line comprises a material preparation line, a feeding line, an inner loop line and an outer loop line; and the device software downloading and testing equipment comprises insulation and voltage resistance testing equipment, program downloading equipment and function testing equipment. The invention further discloses an intelligent production method of the power grid device. According to the invention, process continuous flow production and monitoring are formed, full automation of the power grid device production process is realized, and the production efficiency and the product quality are improved.

Owner:NARI NANJING CONTROL SYST +1

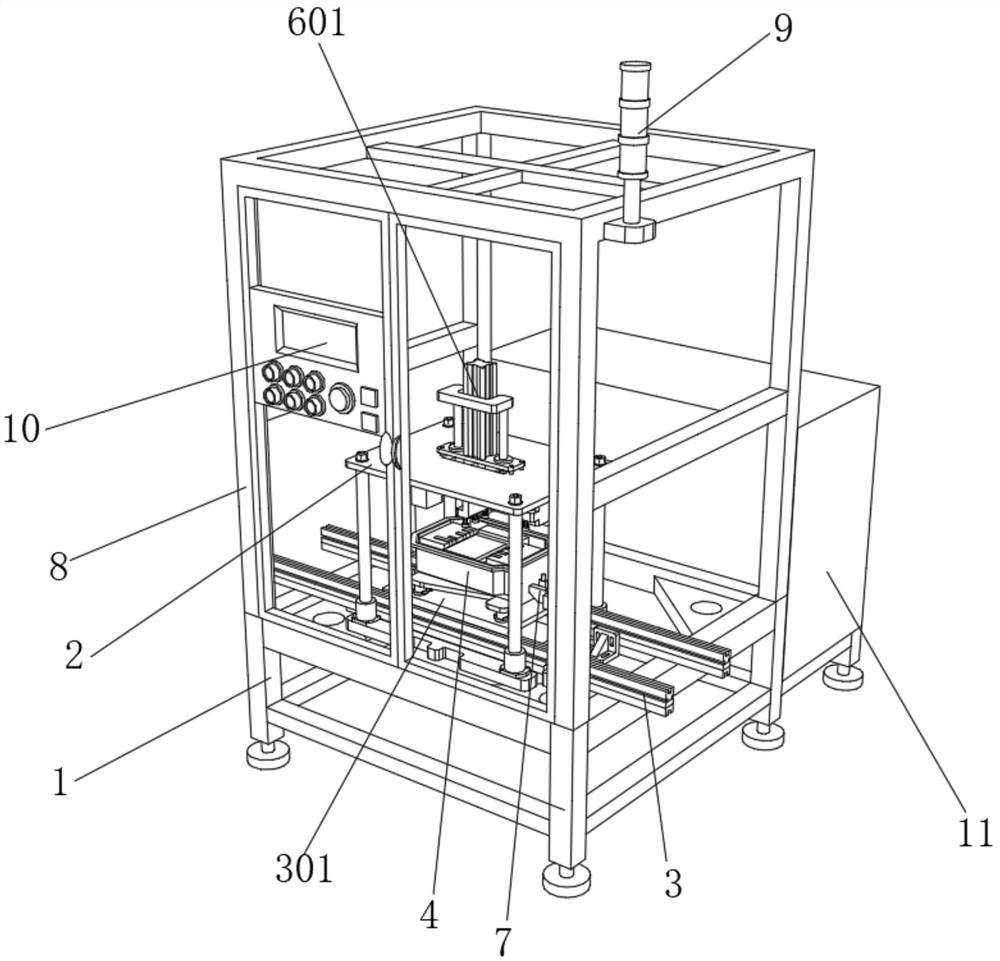

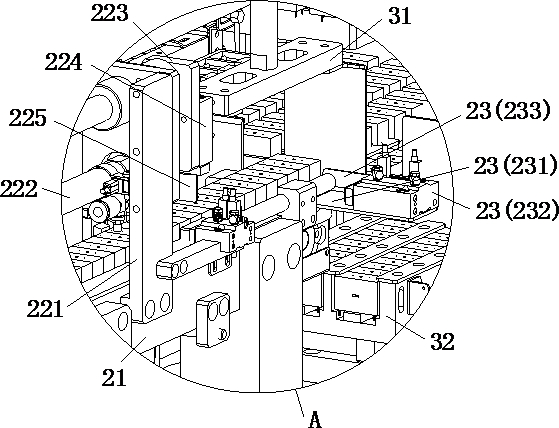

Circuit board test equipment

PendingCN111856250ARealize fully automated testingImprove production test efficiencyPrinted circuit testingSortingTest efficiencyControl system

The invention discloses circuit board testing equipment, which comprises a control system, a feeding mechanism, a first discharging mechanism, a second discharging mechanism and a control platform, wherein the feeding mechanism, the first discharging mechanism, the second discharging mechanism and the control platform are independently connected with the control system, the control platform comprises a to-be-tested layer, a test layer, a probe layer and a circuit board channel, the to-be-tested layer, the probe layer and the test layer sequentially sleeve the circuit board channel from top tobottom, the feeding mechanism is connected with the to-be-tested layer, and the first discharging mechanism and the second discharging mechanism are connected with the circuit board channel. Accordingto the invention, the to-be-tested circuit boards are orderly tested one by one, and are classified and collected according to the test results after the test is completed, so that the full-automatictest of a large batch of to-be-tested circuit boards is realized, the production test efficiency is obviously improved, and the manpower is greatly saved.

Owner:韶关东阳光自动化设备有限公司

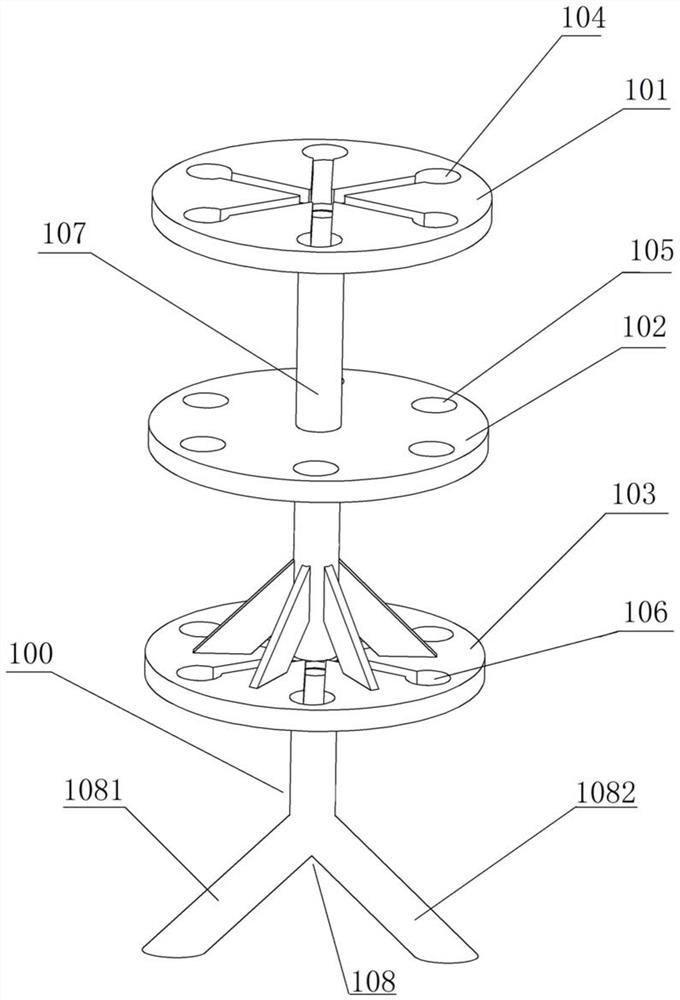

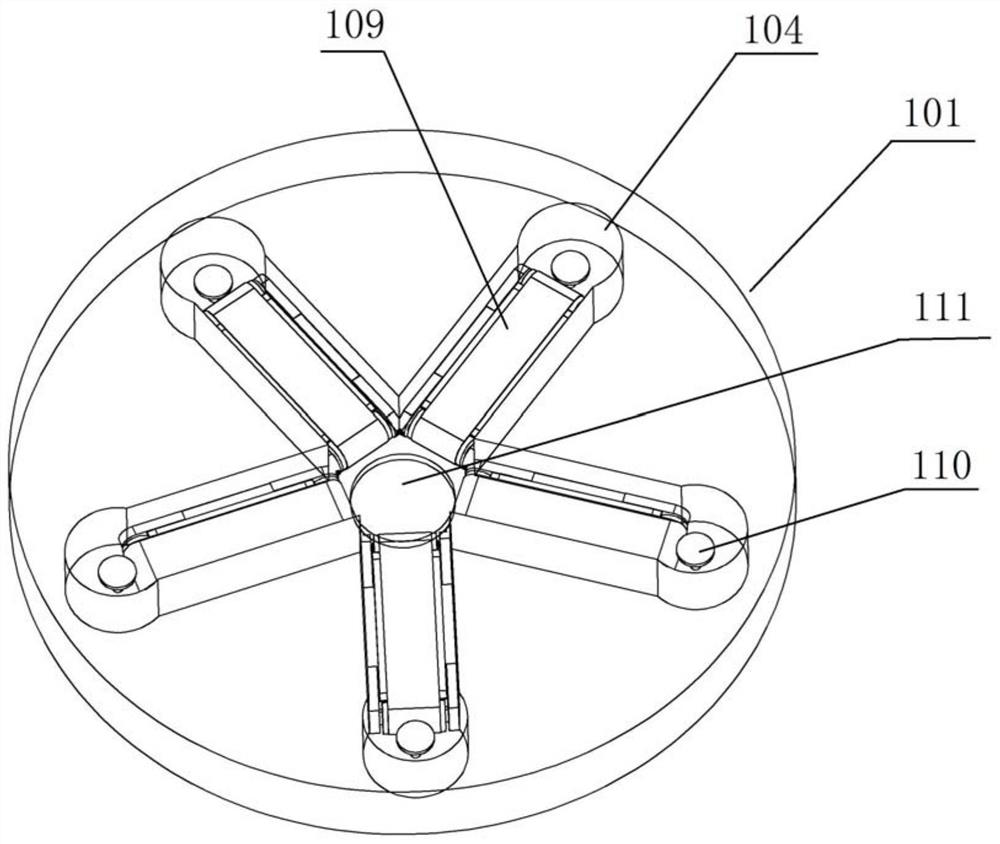

Automatic comprehensive testing machine

PendingCN112363054ARealize fully automated testingEasy to operateMachine part testingConveyorsTest efficiencyCombined test

The invention discloses an automatic comprehensive testing machine which comprises a rack provided with a workbench, a feeding mechanism, a caching and transferring mechanism, a first conveying mechanism, a first grabbing mechanism, an attraction testing mechanism, a second conveying mechanism, a second grabbing mechanism, a four-in-one testing mechanism, a third grabbing mechanism and a discharging mechanism. The feeding mechanism, the caching and transferring mechanism, the first conveying mechanism, the attraction testing mechanism, the second conveying mechanism and the discharging mechanism are sequentially arranged on the workbench from front to back, the first grabbing mechanism is arranged on the workbench above the first conveying mechanism, and the second grabbing mechanism is arranged on the workbench above the second conveying mechanism; and the four-in-one testing mechanism is arranged on the workbench behind the second grabbing mechanism, and the third grabbing mechanismis arranged on the workbench above the discharging mechanism. Five kinds of tests can be sequentially completed on the same equipment, full-automatic testing is achieved, manual labor is effectively reduced, time and labor are saved, and the testing efficiency is improved.

Owner:深圳市达鑫自动化有限公司

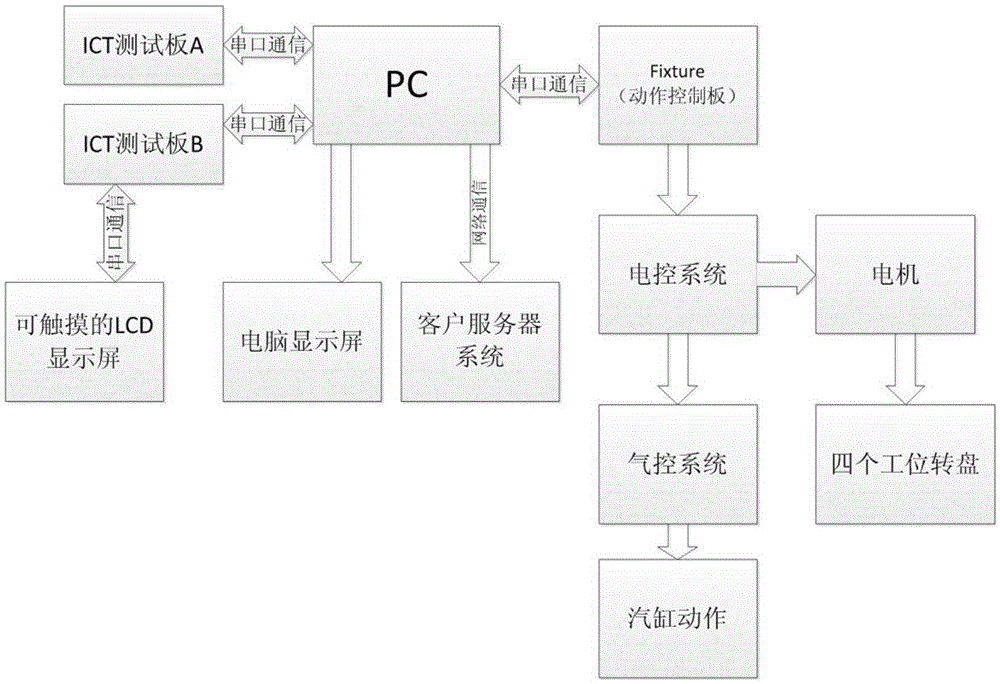

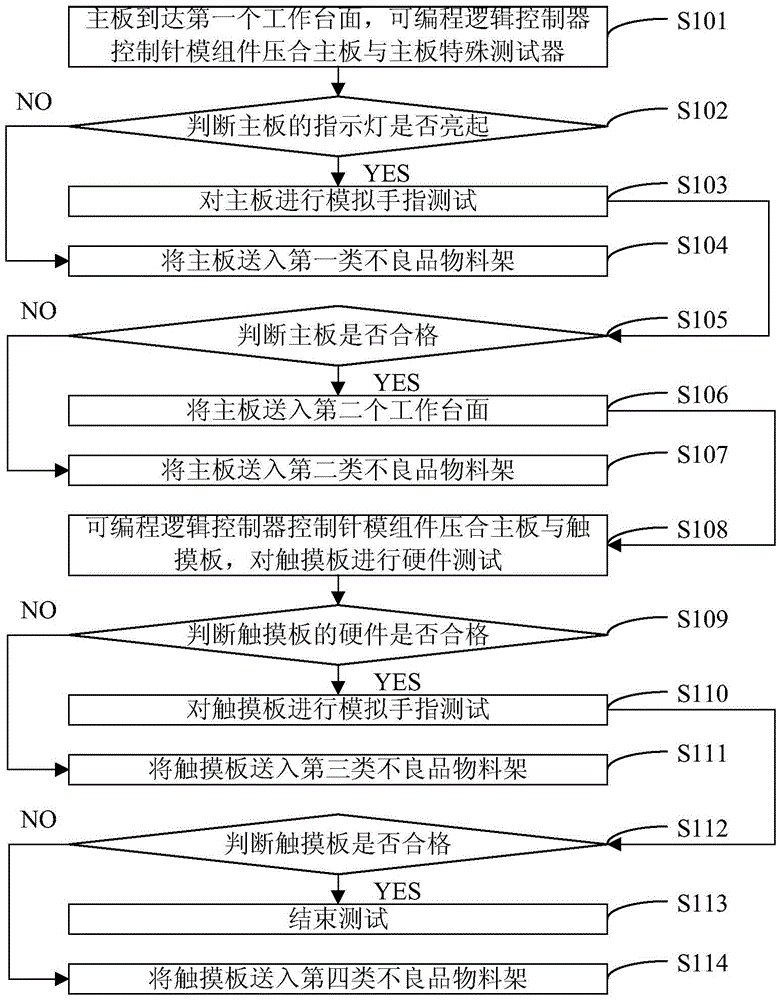

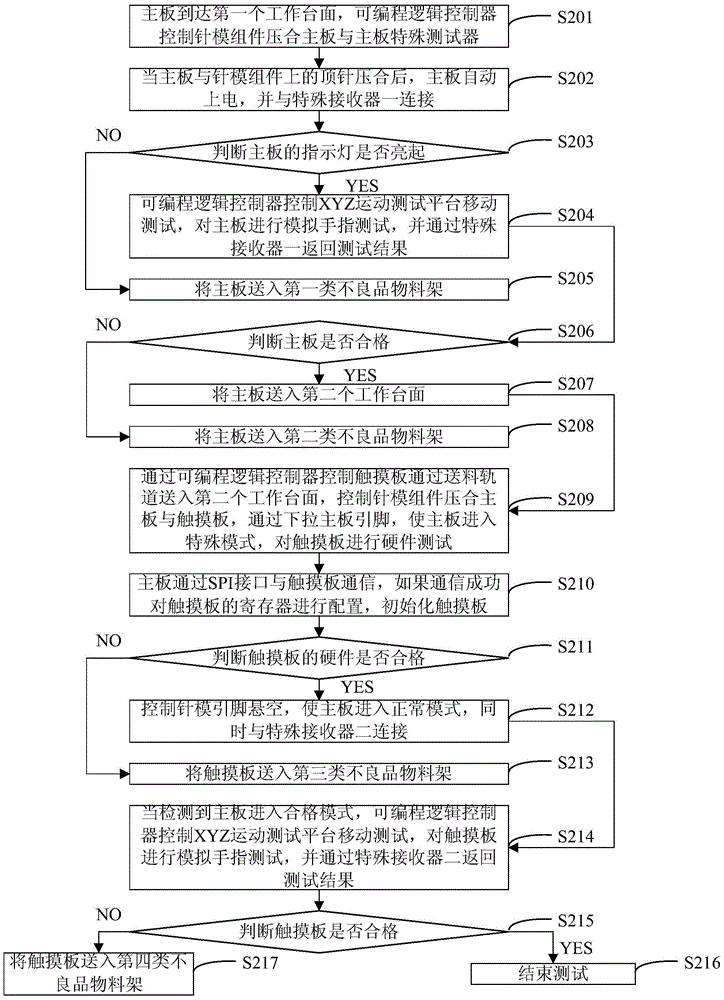

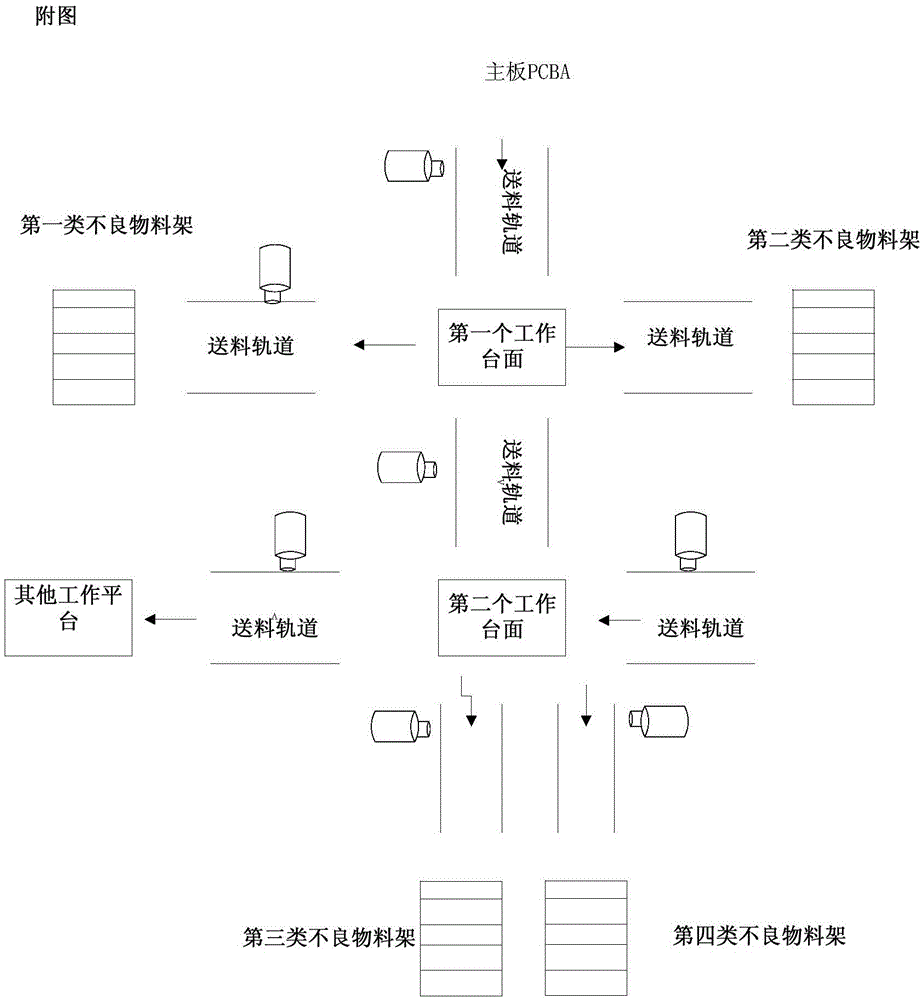

A method and system for realizing automatic testing of touch products

InactiveCN103544084BRealize fully automated testingIncrease productivityDetecting faulty computer hardwareSoftware testing/debuggingProgrammable logic controllerAutomatic testing

The invention discloses a method and a system achieving automatic testing of touch products. The method achieving the automatic testing of the touch products comprises enabling a mainboard to achieve a first working platform, enabling a programmable logic controller to control a needle mold assembly to perform press fit on the mainboard and a mainboard special tester, judging whether a mainboard indicating lamp is lighted or not, sending the mainboard to a first defective product frame if the indicating lamp is not lighted and performing finger testing on the mainboard if the indicating lamp is lighted; judging whether the mainboard is qualified or not, sending the mainboard to a second defective product frame if no and sending the mainboard to a second working platform if yes; enabling the programmable logic controller to control the needle mold assembly to perform press fit on the mainboard and a touch plate, performing hardware testing on the touch plate, judging whether hardware of the touch plate is qualified or not, sending the touch plate to a third defective product frame if not and performing simulated finger testing on the touch plate if yes; judging whether the touch plate is qualified or not, ending the testing if yes and sending the touch plate to a fourth defective product frame if not. The method has the advantages of achieving full automatic testing of the touch products, improving production efficiency and saving production costs.

Owner:SHENZHEN RAPOO TECH

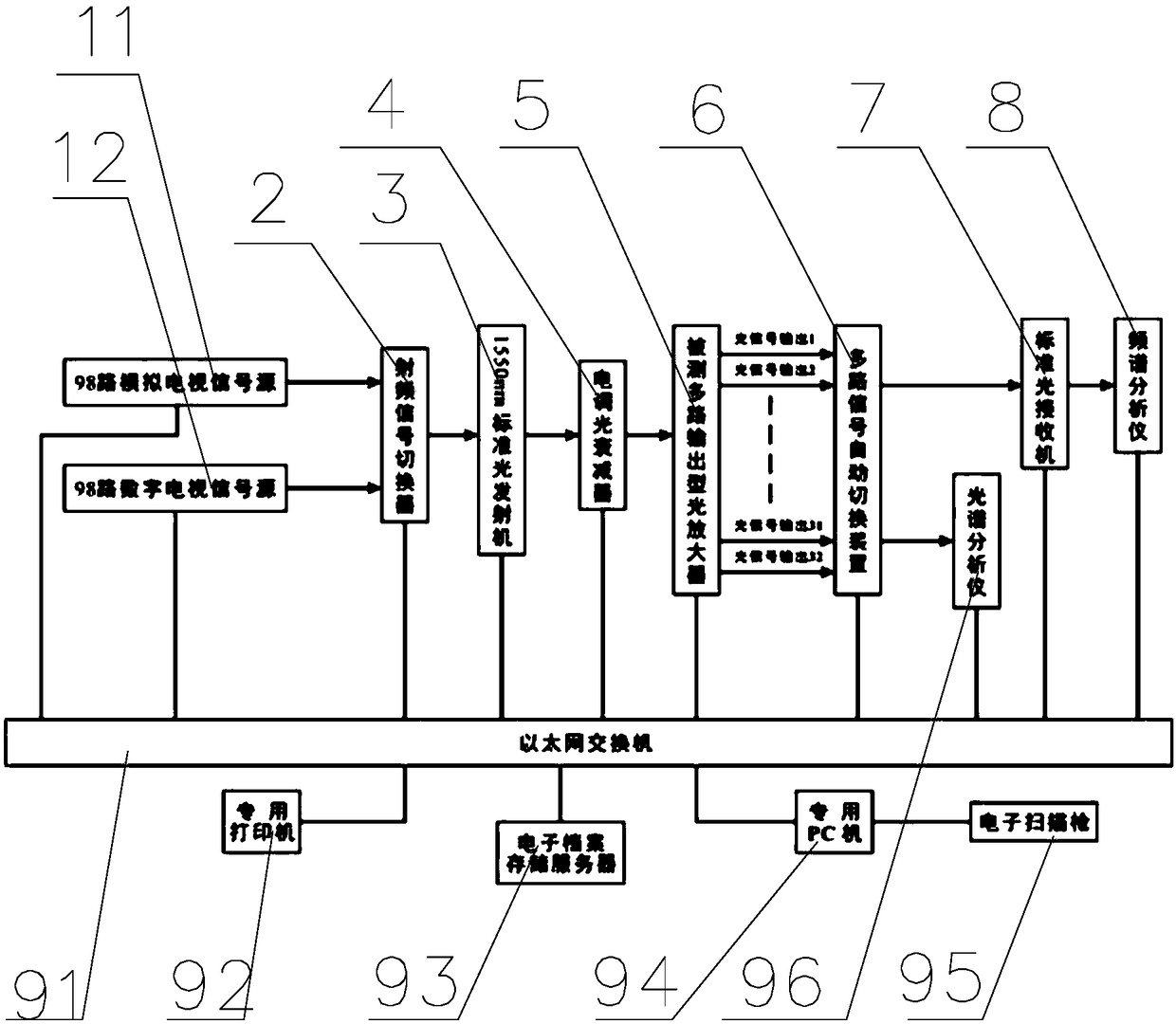

Output type optical amplifier automatic testing device

InactiveCN108377385ARealize fully automated testingImprove test efficiencySpectrum investigationOptical transmission adaptationsSpectrum analyzerOpto electronic

The invention discloses an output type optical amplifier automatic testing device, and belongs to the photoelectric field. The output type amplifier automatic testing device comprises a radio frequency signal switcher, an optical transmitter, an electric dimming attenuator, a tested multi-path output type optical amplifier, a multi-signal automatic switching device, an optical receiver, and a spectrum analyzer; the radio frequency signal switcher is used for connecting a TV signal source; the radio frequency signal switcher, the optical transmitter, the electric dimming attenuator, the testedmulti-path output type optical amplifier, the multi-path signal automatic switching device, the optical receiver and the spectrum analyzer are connected with a computer through the Ethernet.

Owner:杭州万隆光电设备股份有限公司

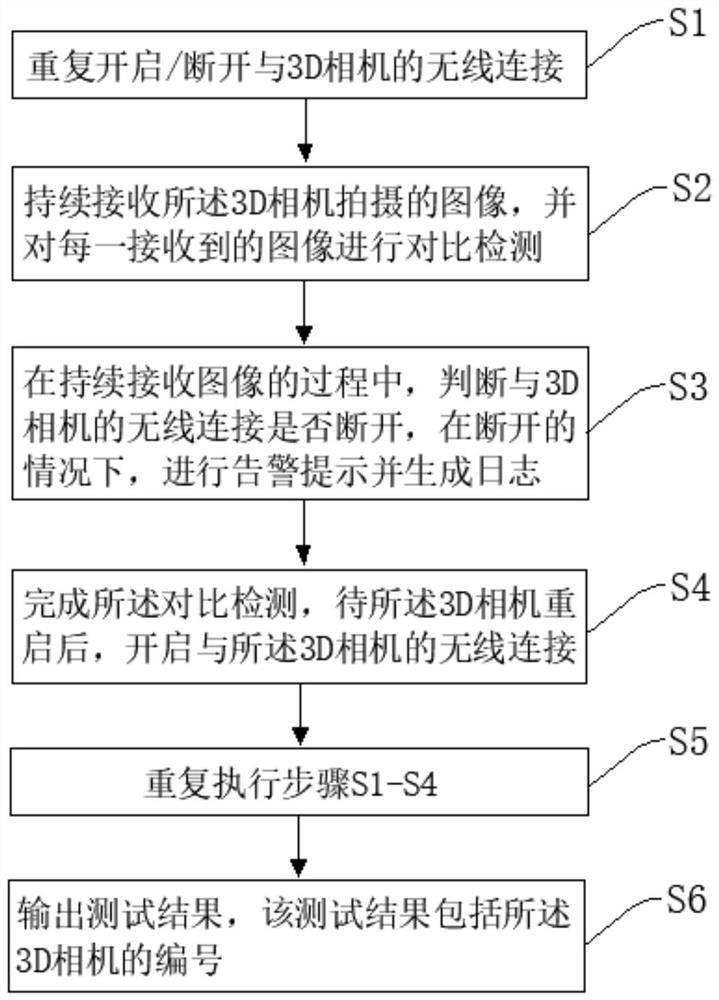

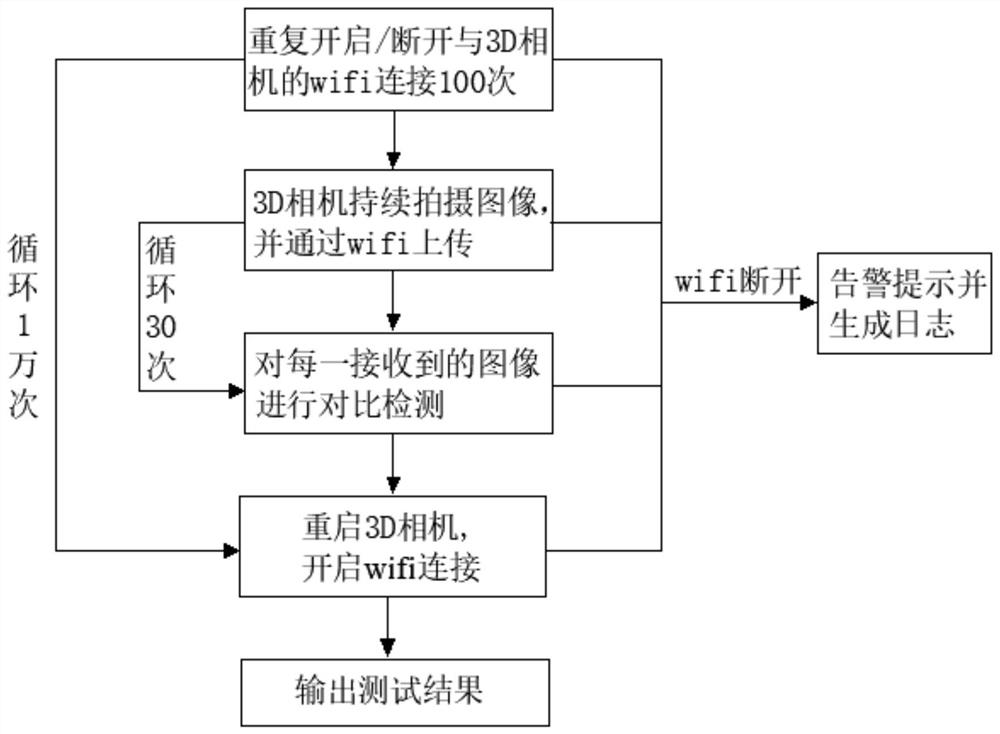

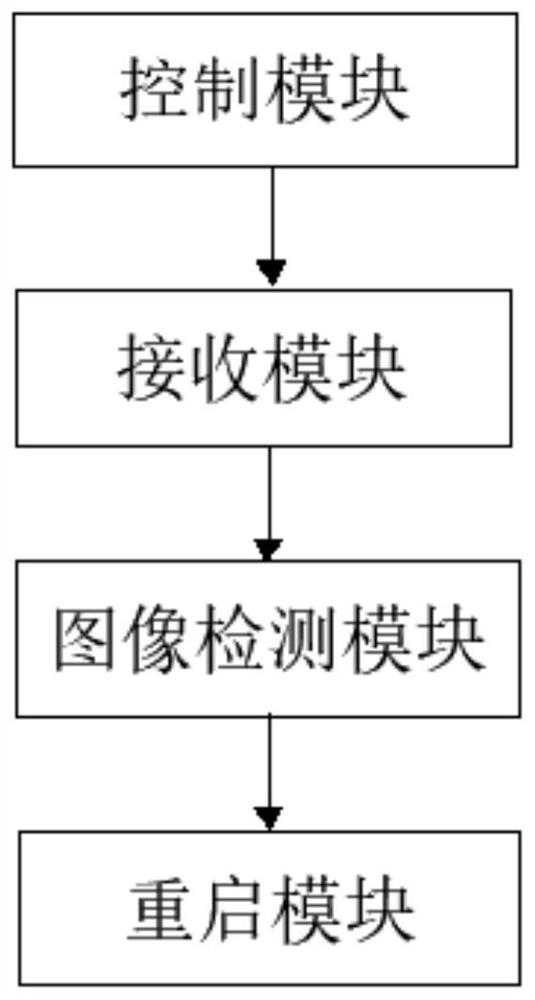

3D camera wireless function stability test method and test device

ActiveCN111064953BRealization of wireless function stabilityRealize fully automated testingTelevision systemsComputer graphics (images)Engineering

The present invention relates to the technical field of automated testing, and discloses a testing method for the stability of wireless functions of a 3D camera, which is applied to a testing device wirelessly connected to the 3D camera, and the method includes: S1) repeatedly opening / disconnecting the 3D camera wireless connection; S2) in the case of turning on the wireless connection with the 3D camera, continue to receive images taken by the 3D camera, and compare and detect each received image; S3) in the process of continuously receiving images , judging whether the wireless connection with the 3D camera is disconnected, and in the case of disconnection, give an alarm prompt and generate a log; S4) complete the comparison detection, and after the 3D camera is restarted, open the connection with the 3D camera; Wireless connection of the camera; S5) Repeat steps S1)‑S4). The method realizes the fully automatic test of the stability of the wireless function of the 3D camera, and has high efficiency and accurate test results.

Owner:BEIKE TECH CO LTD

A batch automated test method for navigation terminal receivers

ActiveCN103293536BGuaranteed repeatabilityRealize fully automated testingSatellite radio beaconingAssembly lineAutomatic testing

The invention relates to a batch automated testing method for a navigation terminal receiver. The batch automated testing method mainly aims at batch navigation receiver testing tasks and quick batch test for batch production of the navigation terminal receiver. Without involvement of an operator or many operators, the batch automated testing method has the advantages of high accuracy, consistency, efficiency and low cost and the like and is mainly applied to analog simulation generation technique of satellite navigation signals, bussing technique, assembly line based testing technique, sampling technique and database storage technique and automatic generation technique of test result report forms.

Owner:BEIHANG UNIV

Terminal charge and discharge automatic test circuit and test method thereof

ActiveCN106291179BRealize fully automated testingSave time and costElectrical testingTest efficiencyMicrocontroller

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

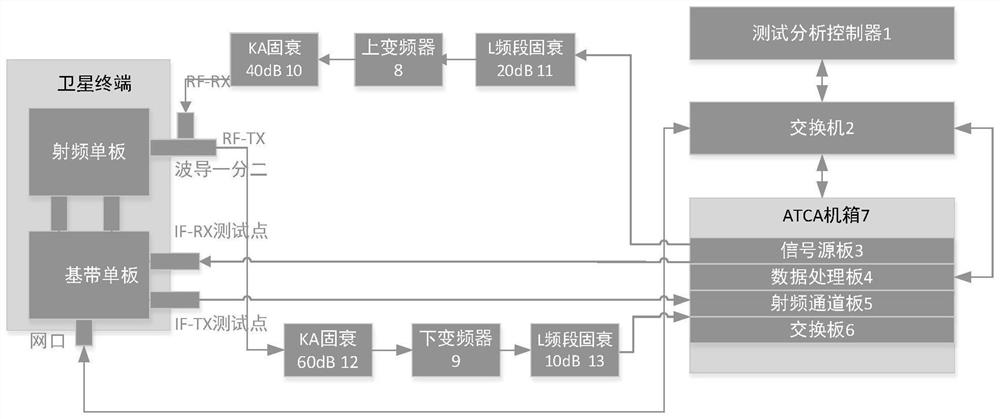

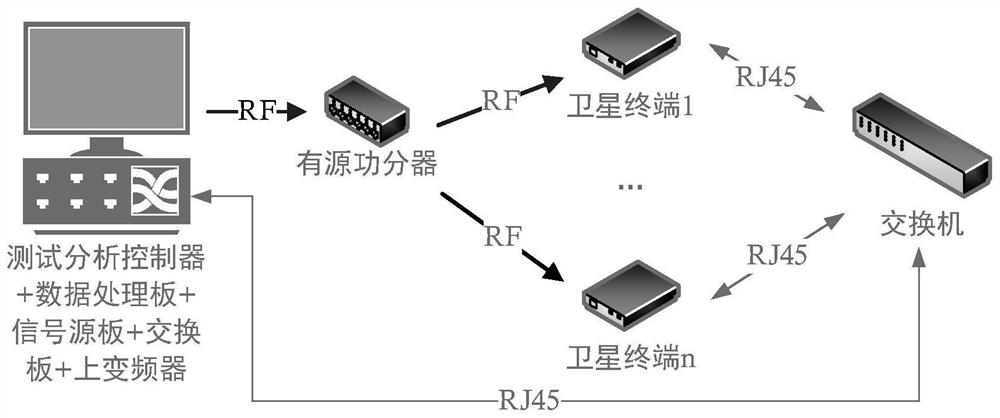

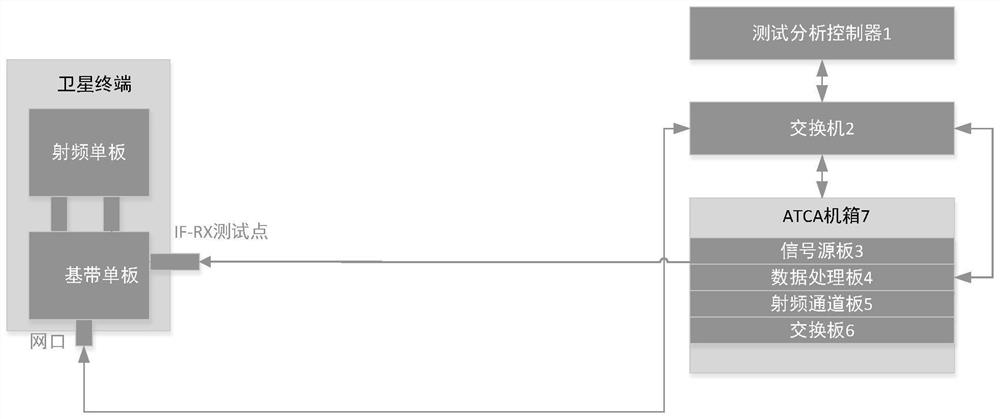

A batch production automation test equipment for satellite terminals

ActiveCN109450576BStreamline the production lineImplement conformance testingRadio transmissionData switching networksTest qualityEngineering

The invention provides a satellite terminal batch production automation test equipment, including: a test analysis controller, a switch, a signal source board, a data processing board, a radio frequency channel board and a switching board, an ATCA chassis, an up-converter, a down-converter, a first Ka solid attenuator, first L-band solid attenuator, second Ka solid attenuator, second L-band solid attenuator, waveguide splitter. The test analysis controller is used to execute each forward test case and send it to the data processing board; for the backhaul use case, it receives and analyzes the IP packets transmitted by the radio frequency channel board to calculate and calculate each radio frequency index, and performs criteria and storage; radio frequency The channel board is used to perform down-conversion, AD conversion, and sampling on the returned L-band signal according to the requirements of the backhaul test case of the test analysis controller, and encapsulate the sampled I and Q signal data into IP packets and send them to the test analysis controller device. The invention can realize the automatic test in the batch production stage of the satellite terminal, improve the test efficiency and ensure the test quality.

Owner:BEIJING SATELLITE INFORMATION ENG RES INST

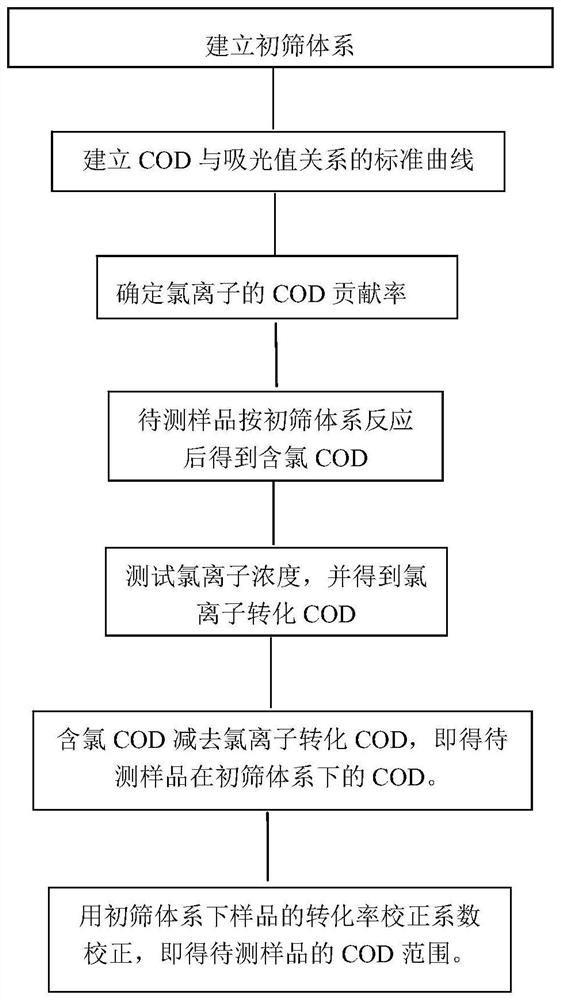

A method for preliminary screening of chemical oxygen demand in chlorine-containing wastewater

ActiveCN108680716BRealize fully automated testingImprove conversion rateTesting waterChemical oxygen demandTest sample

Owner:上海华测品标检测技术有限公司 +1

Automatic test system for single event effect test of DC/DC (direct current/direct current) converter and test method

ActiveCN102539982BRealize fully automated testingAutomatic collectionElectrical testingData displayData acquisition

The invention discloses an automatic test system for a single event effect test of a DC / DC (direct current / direct current) converter. The automatic test system comprises a programmable power supply, a PXI integrated sampling control unit which is connected with an electrical parameter signal control terminal box, an upper PC (personal computer) which is connected with the PXI integrated sampling control unit, and a LabVIEW test software for monitoring an electrical parameter signal and analyzing and processing the electrical parameter signal. The invention also discloses a test method for the automatic test system. By the automatic test system and the test method, the single event effect test data of the DC / DC converter can be tested fully automatically, automatic high-speed data acquisition, automatic product selection, automatic product loading, automatic power setting, test parameter setting, real-time acquired data display and data replay are integrated, the single event effect test efficiency of the DC / DC converter is greatly improved, and the damage to the body of a tester who enters a radiation room repeatedly during the test can be avoided.

Owner:NO 43 INST OF CHINA ELECTRONICS TECH GRP CETC

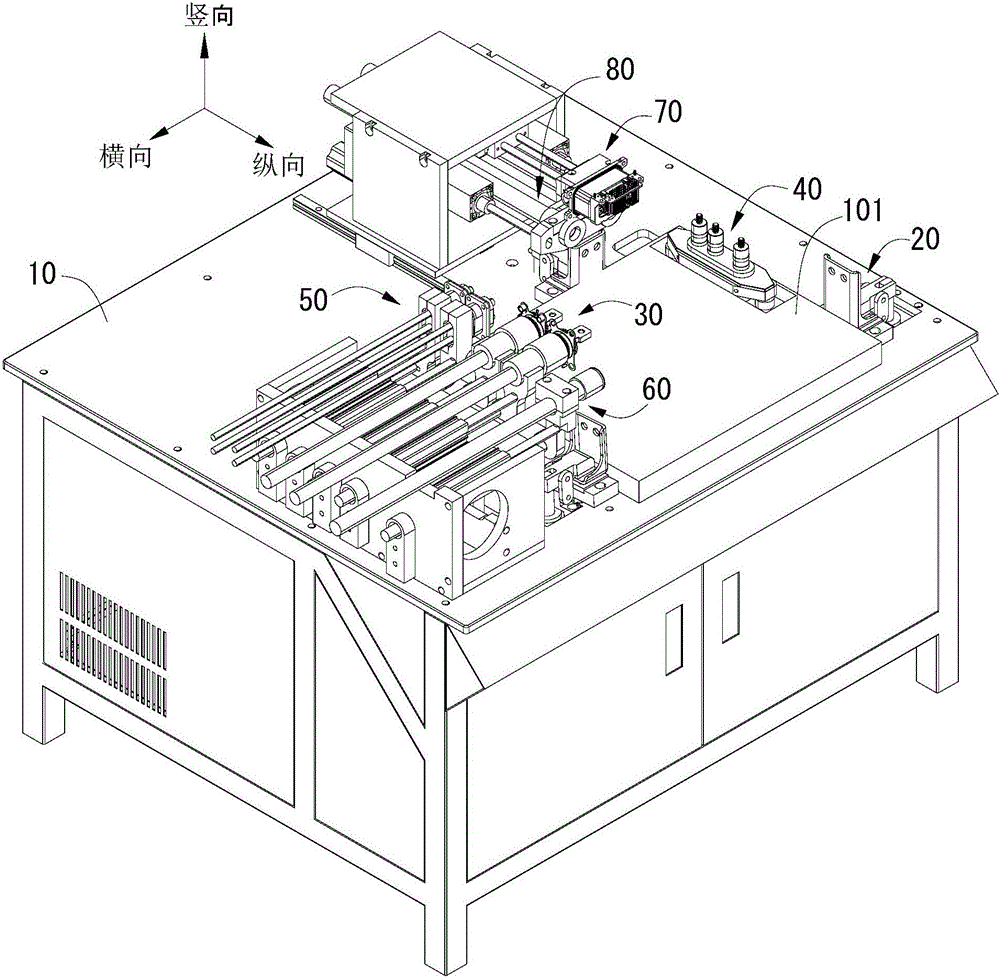

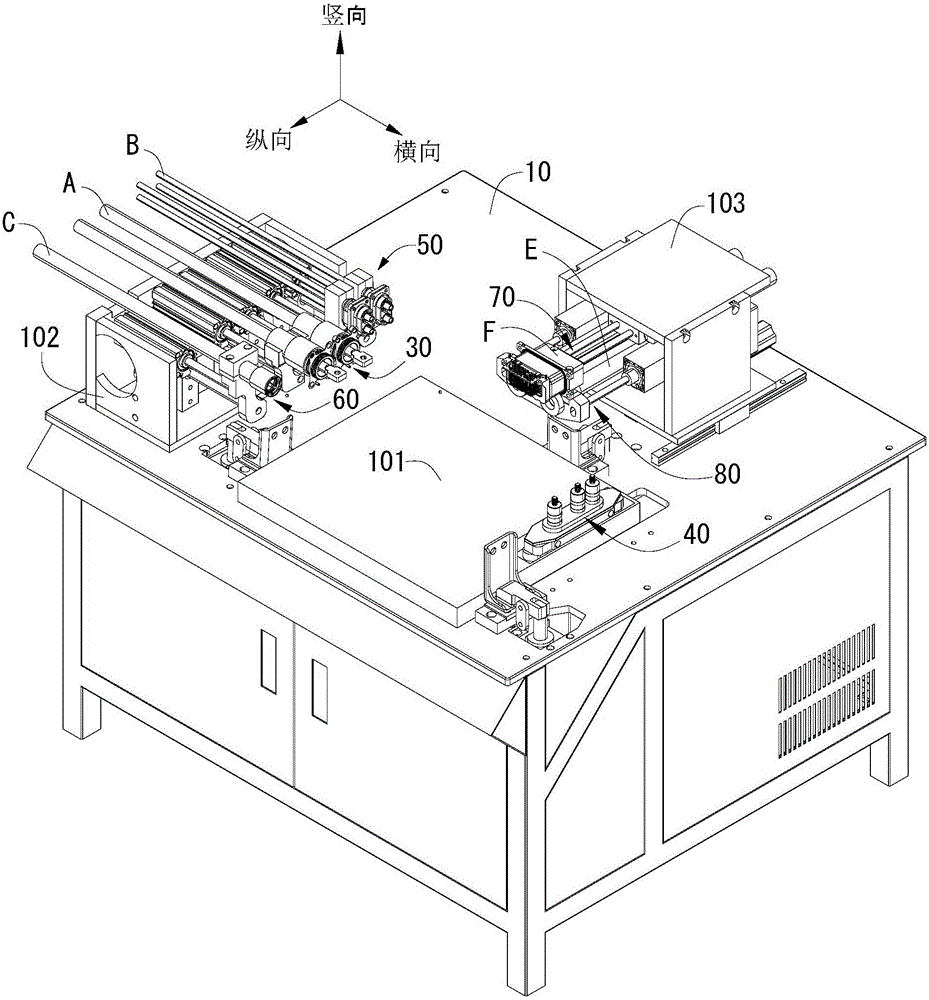

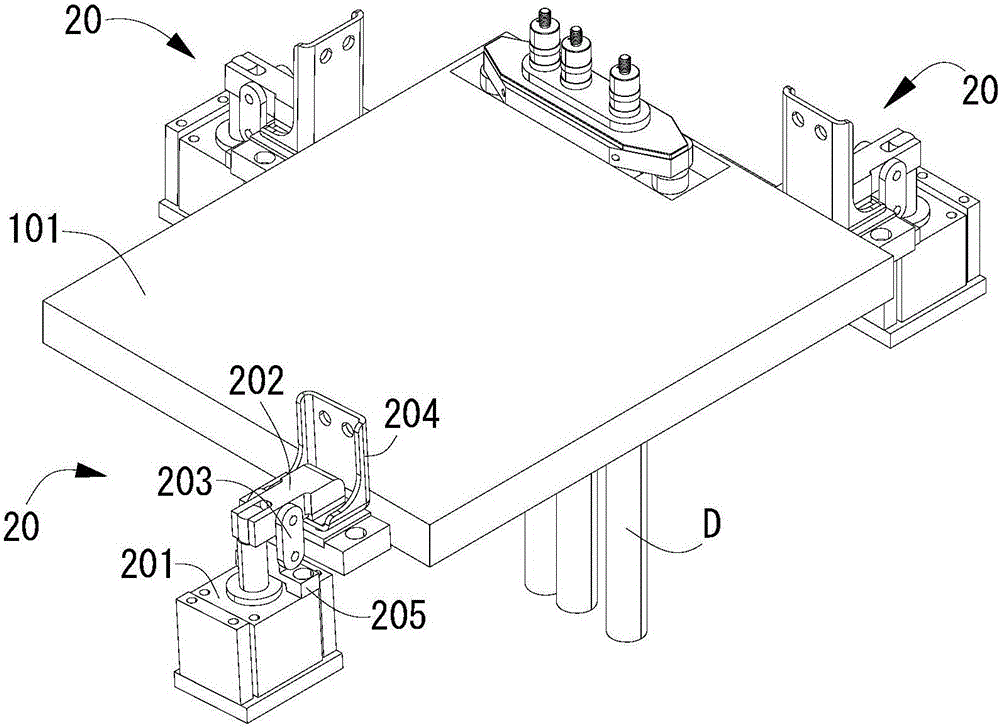

New energy automobile electric control box full-automatic detection equipment

ActiveCN105824309ARealize fully automated testingImprove work efficiencyElectric testing/monitoringAutomatic test equipmentNew energy

The invention relates to a piece of new energy automobile electric control box full-automatic detection equipment, comprising a workbench, at least two positioning mechanisms, first and second power source plugging mechanisms, first and second energy detection plugging mechanisms, a cooling water input plugging mechanism, and a power system plugging mechanism. The workbench is provided with a placing area. The positioning mechanisms are used for clamping and fixing an electric control box to the placing area. The first and second power source plugging mechanisms are used for plugging first and second power lines into first and second power interfaces of the electric control box respectively. The first and second energy detection plugging mechanisms are used for plugging first and second energy detection lines into first and second energy interfaces of the electric control box respectively. The cooling water input plugging mechanism is used for plugging a cooling water inlet pipe into a cooling water interface of the electric control box. The power system plugging mechanism is used for plugging a power detection line into a power system interface of the electric control box. With the equipment, full-automatic test is realized. Compared with manual operation, the work efficiency is higher, and plugging is safer and more reliable.

Owner:唐军

Power Automatic Test System

ActiveCN105548787BEasy transferEasy to removePower supply testingTest efficiencyTest Standardization

The present invention discloses a power supply automatic test system. The power supply automatic test system comprises a feeding system, a detection system and a discharge system which are arranged in order. The feeding system includes a jig in-position lifting mechanism, a first conveying chain and a code scanning mechanism which are arranged in order. The conveying directions of the first conveying chain and the second conveying chain are opposite, and the second conveying chain is configured to convey the jig having been tested to the jig in-position lifting mechanism. The detection system comprises a HI-POT detection device, an ATE detection device, a PE detection device and an AC end pull-out device which are arranged in the order from left to right. An upper conveying chain and a middle conveying chain are configured to convey the jig to pass through the HI-POT detection device, the ATE detection device, the PE detection device and the AC end pull-out mechanism in order. The discharge system is located at the tail end of the detection system, and a DC end pull-out mechanism for the jig of the detection system is configured to pull out the DC end of the supply power. The power supply automatic test system is capable of automated implementation of continuous test of all parameters of a power supply, improvement of test standardization and enhancement of test precision and test efficiency.

Owner:DONGGUAN GUANJIA ELECTRONICS EQUIP

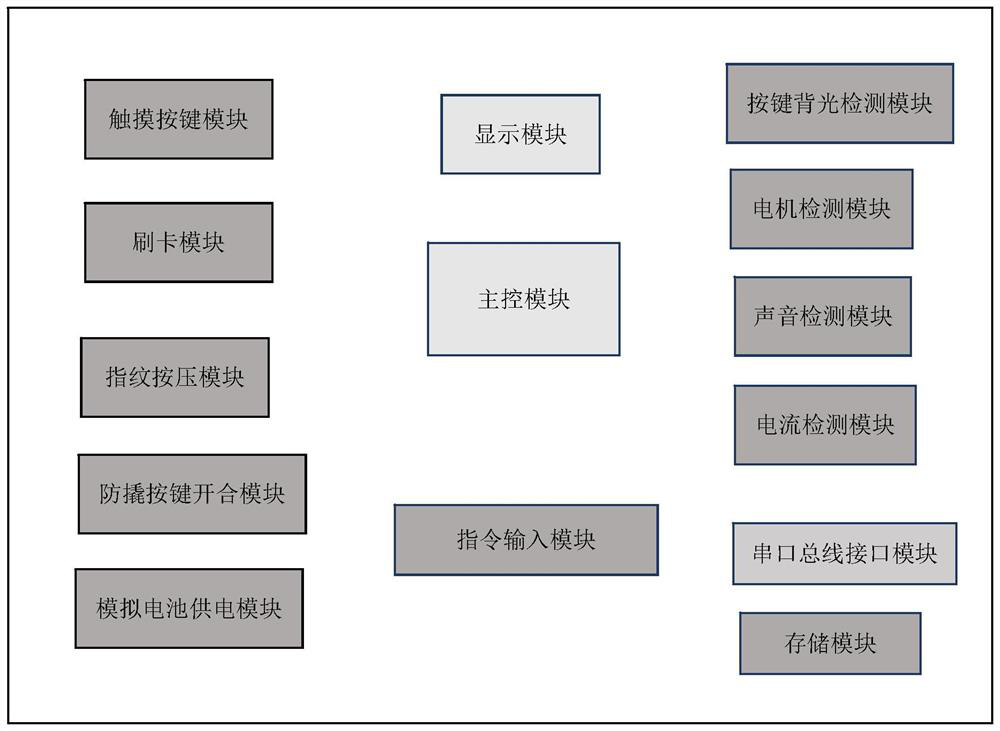

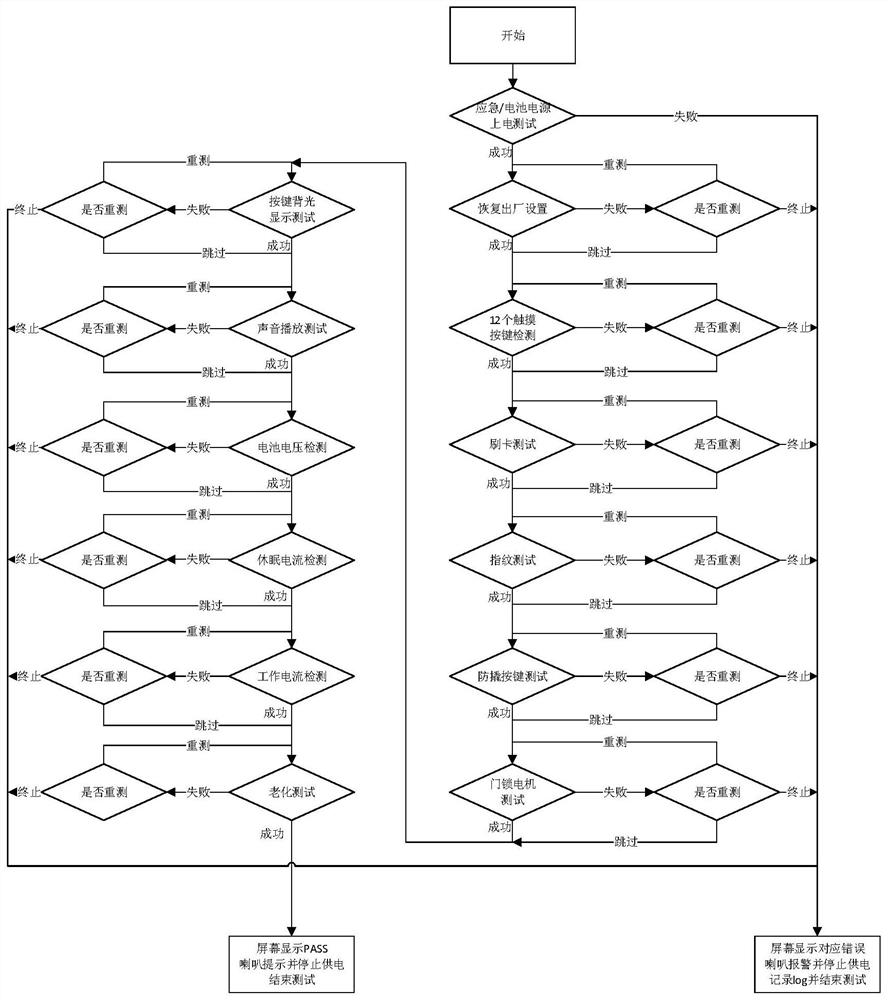

Automatic testing device and system for intelligent door lock

PendingCN113721089ARealize fully automated testingImplement automatic detectionDynamo-electric machine testingControl engineeringComputer science

The invention discloses an automatic testing device and system for an intelligent door lock. The device comprises a main control module, a plurality of test modules and a plurality of detection modules, wherein the main control module determines a current test link according to the read configuration information; and according to the current test link, a corresponding test module is controlled to execute test operation of the current test link on the intelligent door lock, the main control module obtains a test result of the current test link through a corresponding detection module, or the main control module determines the test result of the current test link through feedback information of the intelligent door lock until the test of all the test links in the configuration information is completed. According to the technical scheme, full-automatic testing of the intelligent door lock is achieved.

Owner:ANYKA (GUANGZHOU) MICROELECTRONICS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com