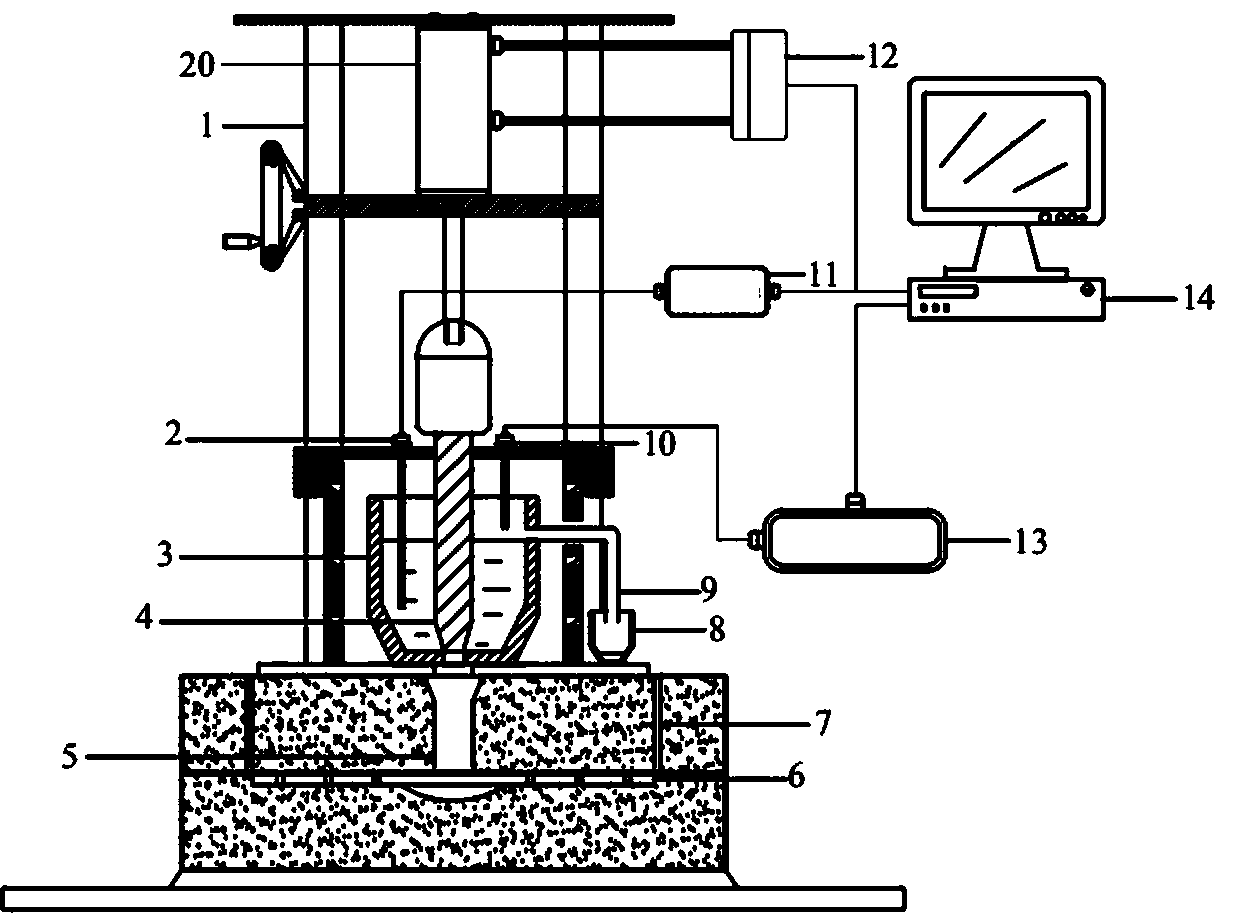

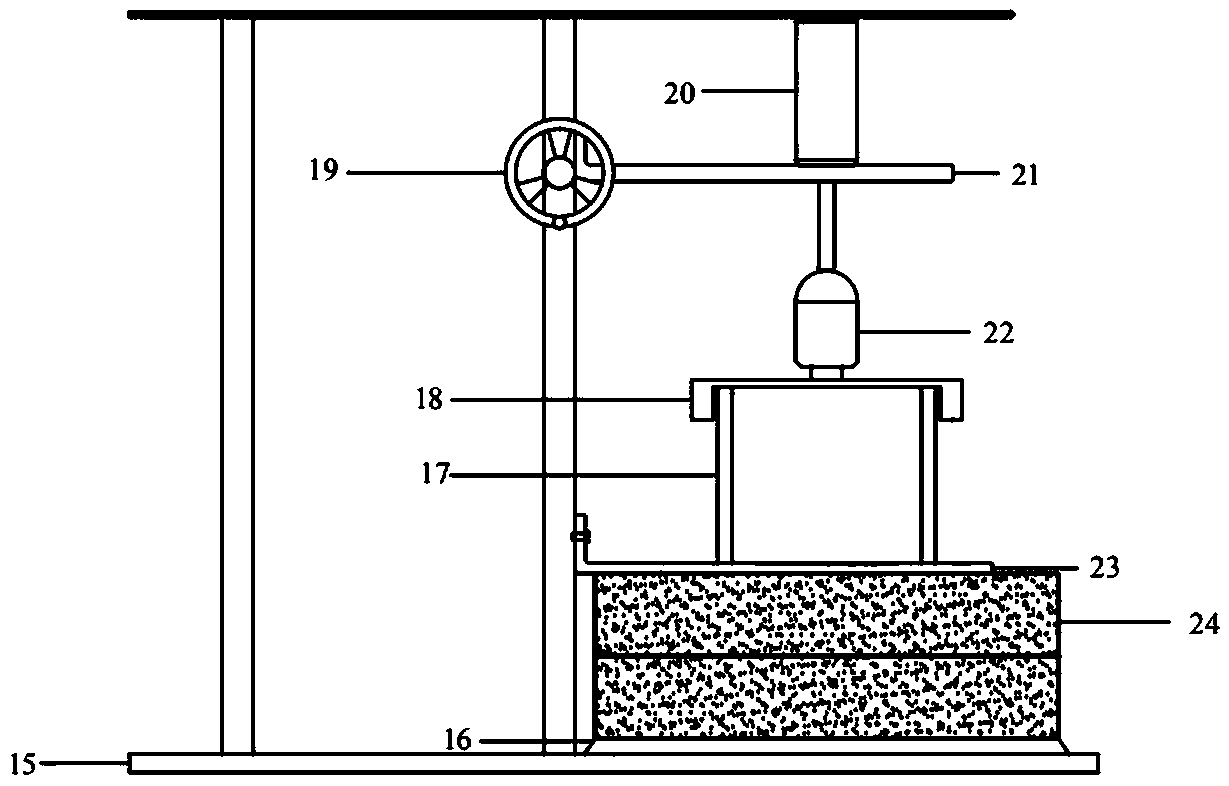

Aluminum alloy fluidity precise testing device and method

A testing device and technology of aluminum alloy, applied in the direction of DC flow characteristic measurement, etc., can solve the problem that the fluidity cannot be accurately measured, and achieve the effect of reducing errors, realizing precise control, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0031] The distance between the points of the three-helix mold used in the test experiment is 50mm. The lengths of the three helixes are measured and the average value is sufficient. The casting with a larger average value has better fluidity.

[0032] Configure the ZL205A aluminum alloy according to the following ratio.

[0033] element Cu mn Ti Cd V Zr B Al Content / wt.% 4.9 0.5 0.27 0.16 0.12 0.15 0.06 the bal

[0034] Assemble, switch on, and debug the device according to the steps, set the sensor parameters, the preheating temperature is 750°C, and the casting temperature is 710°C. Pour the refined aluminum liquid into the crucible and overflow to the overflow tank. Observe the electronic scale and measure the weight of the aluminum liquid to be 3.02kg. When the temperature of the aluminum liquid reaches 710℃, the electric cylinder rises at a speed of 0.1m / s. flow into the cavity. After the molten aluminum is cooled and solidified,...

example 2

[0039] Configure the ZL114A aluminum alloy according to the following ratio.

[0040]

[0041] Assemble, switch on, and debug the device according to the steps, set the sensor parameters, the preheating temperature is 750°C, and the casting temperature is 710°C. Pour the refined aluminum liquid into the crucible and overflow to the overflow tank. Observe the electronic scale and measure the weight of the aluminum liquid to be 3.00kg. When the temperature of the aluminum liquid reaches 710°C, the electric cylinder rises at a speed of 0.06m / s. flow into the cavity. After the molten aluminum is cooled and solidified, take it out of the box.

[0042] Using a traditional fluidity device, repeat the above operation steps by manual casting. After repeating 23 times, the triple helix casting of ZL114A, at 710°C, the maximum flow length L max 607mm, minimum flow length L min is 549mm, the difference between the maximum flow length and the minimum flow length|L max -L min |<58mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com