Turntable automatic testing device and method

A technology of automatic testing and turntable, applied in the direction of electronic circuit testing, etc., to achieve the effect of fully automatic testing, improving productivity and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

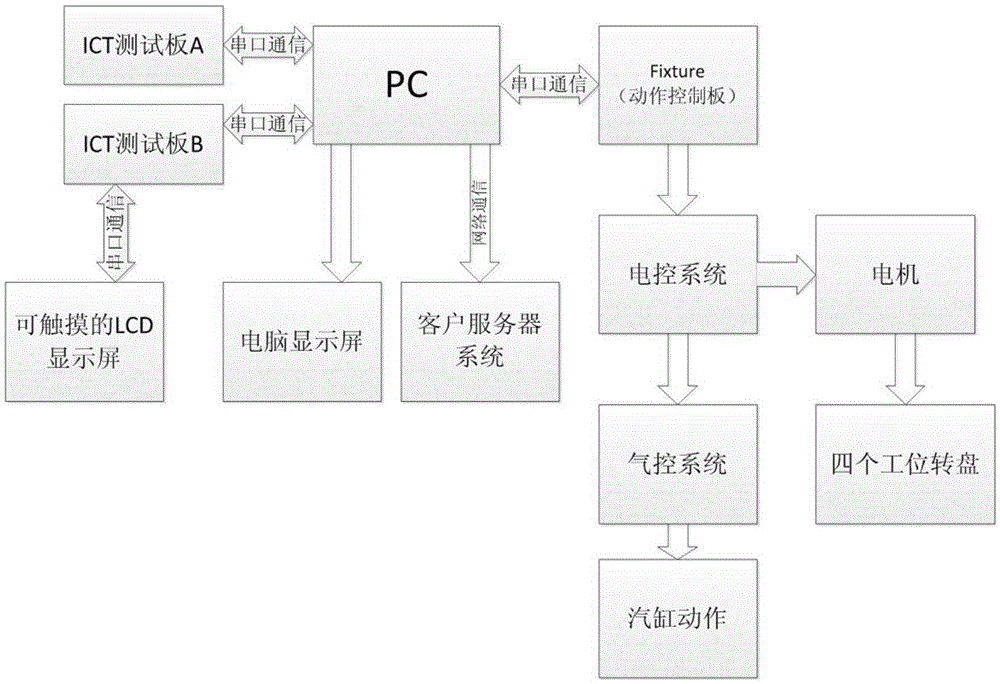

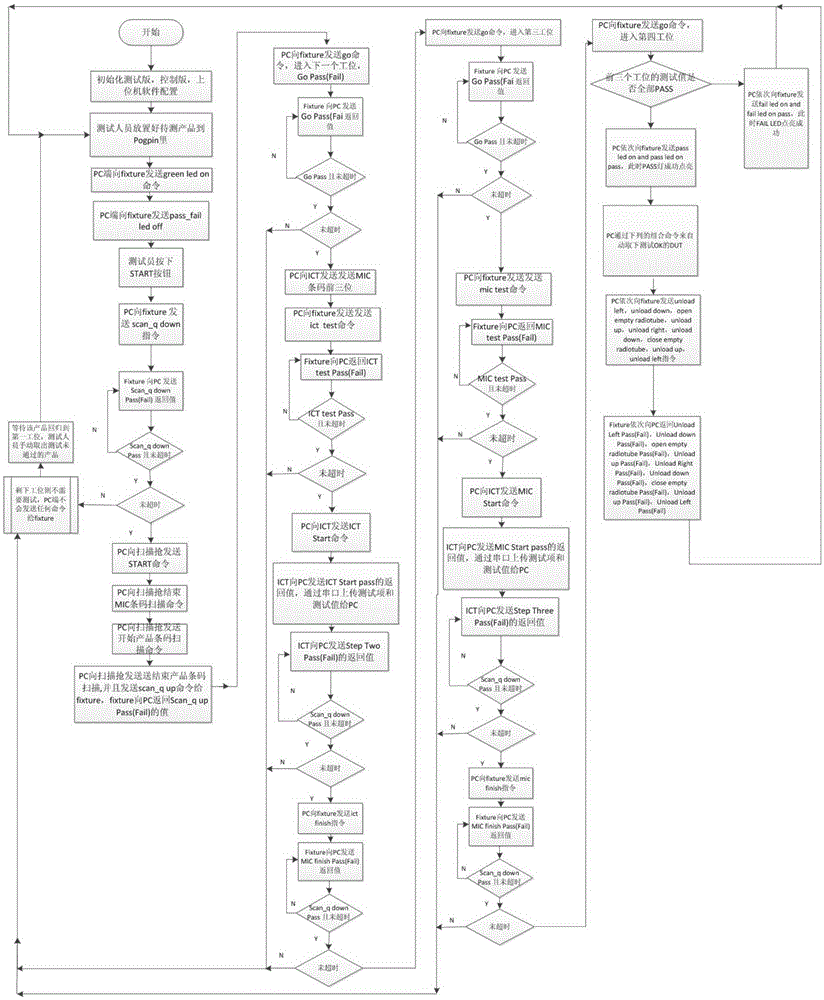

[0032] Please refer to attached figure 1 As shown, the hardware involved includes four station turntables driven by motors, electric control system, air control system, cylinder, Fixture (action control board), PC, test board, touchable LCD display, Computer display screen and customer service system, etc.

[0033] Among them, the test boards of each test part are set on the cylinders, driven by the cylinders, and the air control system controls the lifting of the cylinders, so that the test boards are in contact with the chips to be tested, so as to achieve the purpose of testing.

[0034] The test chips are placed in the stations of the four-station turntable, and the turntable is controlled by the electric control system to rotate, so that the test chips are tested sequentially through different test boards.

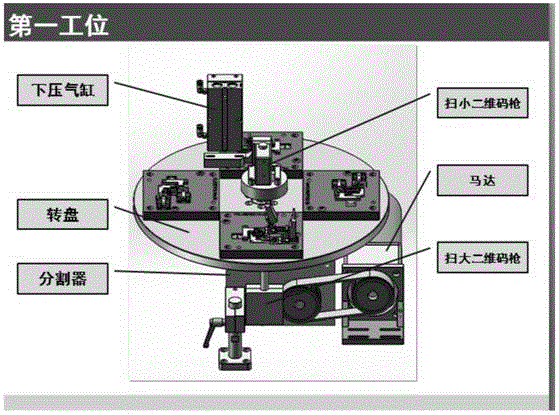

[0035] figure 2 As shown, it is the turntable automatic test device realized by the present invention, which includes a motor, a turntable and a barcode scannin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com