Shopping cart conveying system

A technology of conveying system and trolley, which is applied in the field of shopping trolley conveying system, horizontal transmission, and trolley transportation between two floors. It can solve the problems of high production cost, overturning, long ramp distance, etc., and achieve low maintenance cost. , high conveying efficiency and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

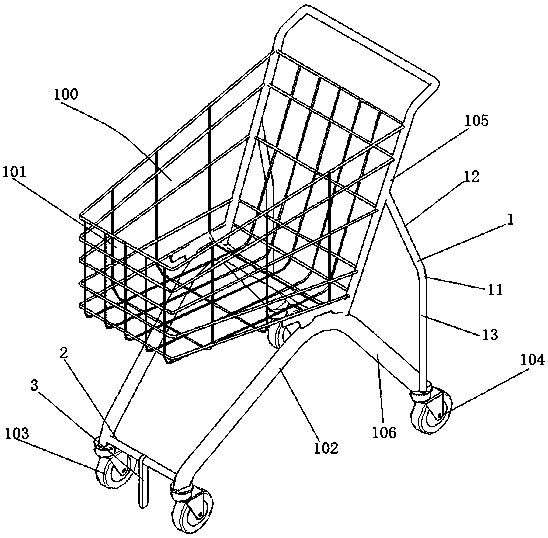

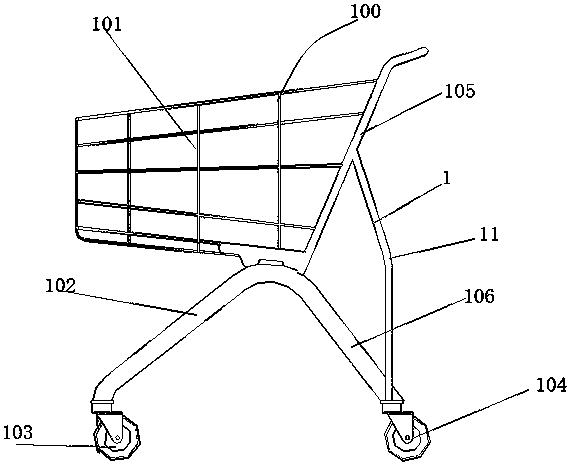

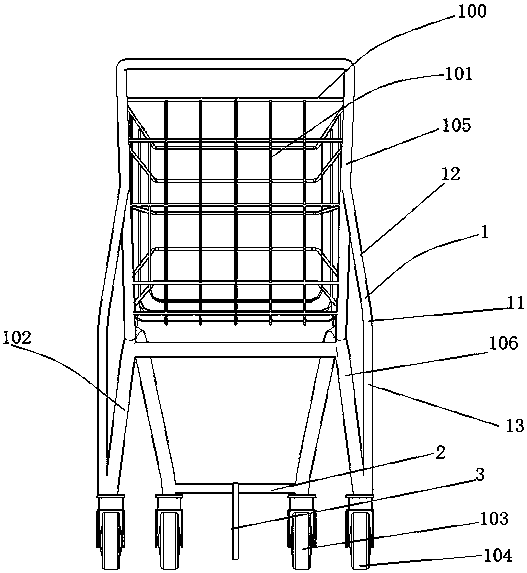

[0054] refer to Figure 1~Figure 12 , a shopping trolley conveying system provided by the present invention is used for transporting a trolley 100 between a low position and a high position. Shopping rack 102 is provided with front wheel 103 corresponding to trolley 100 head end respectively, and rear wheel 104 is respectively provided with corresponding trolley 100 tail end. The shopping frame 101 corresponds to the height direction both sides 105 tops of one side of the two rear wheels 104, and the lower ends are respectively connected to the support bars 106 at the end of the two shopping racks 102 near the rear wheels; On the outside of the bracket rod 106 at one end of the wheel 104, the middle parts of the two guide rods 1 are bent to form a bent part 11, and the guide rod 1 is divided into an upper guide part 12 and a lower guide part 13, and the upper guide part 12 and the lower guide part 13 are clamped. The angle is an obtuse angle; a connecting rod 2, the two ends ...

Embodiment 2

[0067] see Figure 12~Figure 18 The shopping frame 101 of the trolley 100 corresponds to the two rear wheels 104, and the lower ends of the two sides 105 in the height direction respectively form extensions 107 downwards, and the two sides 105 of the shopping frame 101 cooperate with the extensions 107 to form the guide pole 9. The blocking block 7 drives the trolley 100 to guide the pole 9 and slide along the length direction of the guide pole 9, so as to drive the trolley 100 to run between the low position and the high position, so as to realize the transportation of the trolley 100 between the low position and the high position; The extensions of the guide struts 9 extend to the outer upper parts of the two support rods 106 at one end of the two shopping shelves 102 near the rear wheels 104 . All the other are with embodiment 1.

Embodiment 3

[0069] see Figure 19 , during the downward conveying process of the trolley 100, the blocking block 7 drives the two support rods 106 of the two shopping racks 102 of the trolley 100 close to the rear wheel 104 side, and slides along the length direction of the support rods 106, driving the trolley 100 to run from a high position to the low position to realize the downward conveying of the trolley 100 between the high position and the low position. All the other are with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com