Multi-block safety tire pressure balancing method

A technology of air pressure balance and safety tires, applied in the field of transportation, can solve problems such as unbalanced and stable tire pressure, and achieve the effect of avoiding the reduction of gas in the tire and increasing air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a multi-block safe tire air pressure balancing method, including the following steps:

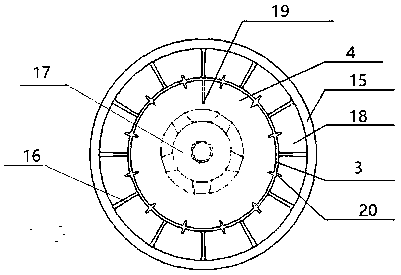

[0030] In the first step, the airbag layer 16 and the hollow layer 4 are arranged on the tire; the airbag layer 16 is arranged on the outer ring of the tire and is composed of a plurality of independent small airbags 18;

[0031] The airbag layer in the first step includes a plurality of small airbags of different shapes and sizes. .

[0032] In the second step, an air pressure balance layer 3 that can be unidirectionally inflated to both is provided between the airbag layer 16 and the hollow layer 4;

[0033] The third step is to inflate the air pressure balance layer 3 to increase the air pressure of the layer;

[0034] In the third step, the air pressure of the air pressure balance layer 3 is usually controlled within a range of 0.1-1.2 MPa.

[0035] In the fourth step, the gas in the air pressure balance layer 3 is inflated in one direction to each sma...

Embodiment 2

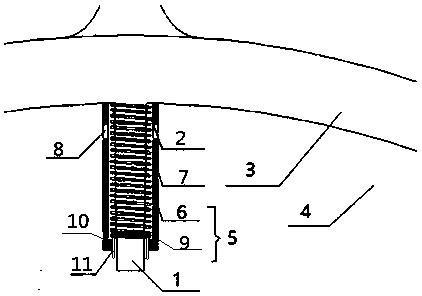

[0044] like figure 2 As shown, the difference between this embodiment and Embodiment 1 is that an inflation and deflation valve 19 is provided, which includes a valve 1 and an outer air passage 2 arranged outside the valve 1, and the valve 1 and the air pressure balance layer 3 connected to adjust the air pressure of the air pressure balance layer 3; the outer air channel 2 communicates with the hollow layer 4 for adjusting the air pressure of the hollow layer 4; the outer air channel 2 is provided with an isolating device 5 for isolating the hollow layer 4 It communicates with the outside world and opens the isolation device 5 to release the gas in the hollow layer 4 .

[0045] Among them, the valve 1 generally includes a valve body and a valve core; the valve core is located inside the valve body, and is mainly used to realize the air intake of the tire and prevent the tire from leaking; the outer wall of the valve 1 is provided with threads, which can be used to connect T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com