Numerical control turret reliability constant-speed and acceleration test device and method

A numerical control turret and accelerated test technology, applied in the direction of measuring devices, testing of mechanical parts, testing of machine/structural parts, etc. Steps, the effect of shortening the test preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

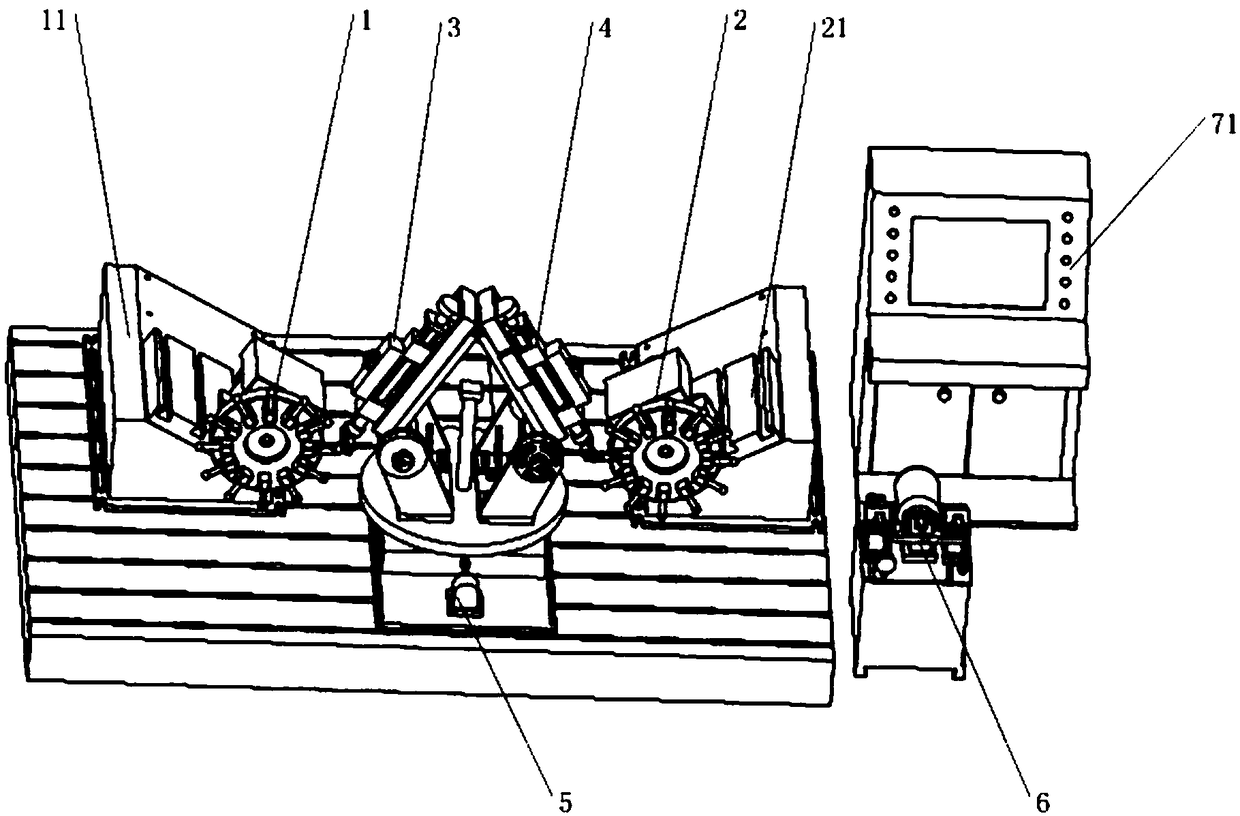

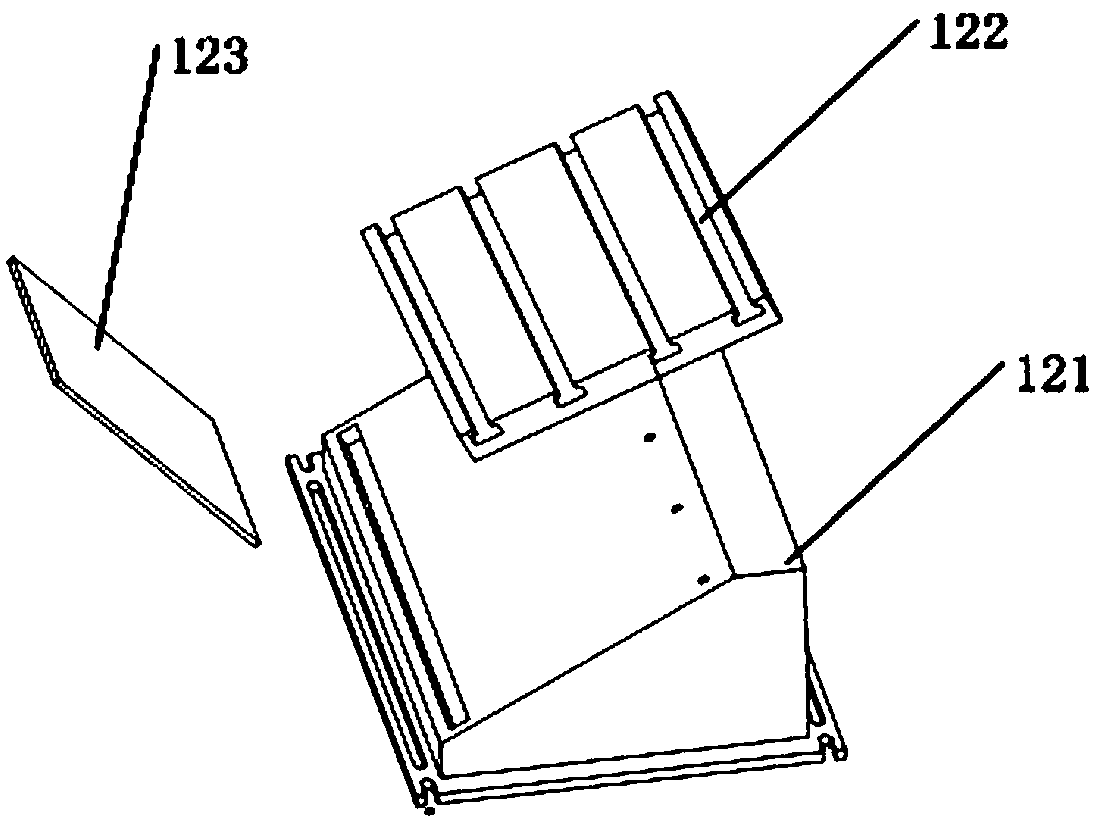

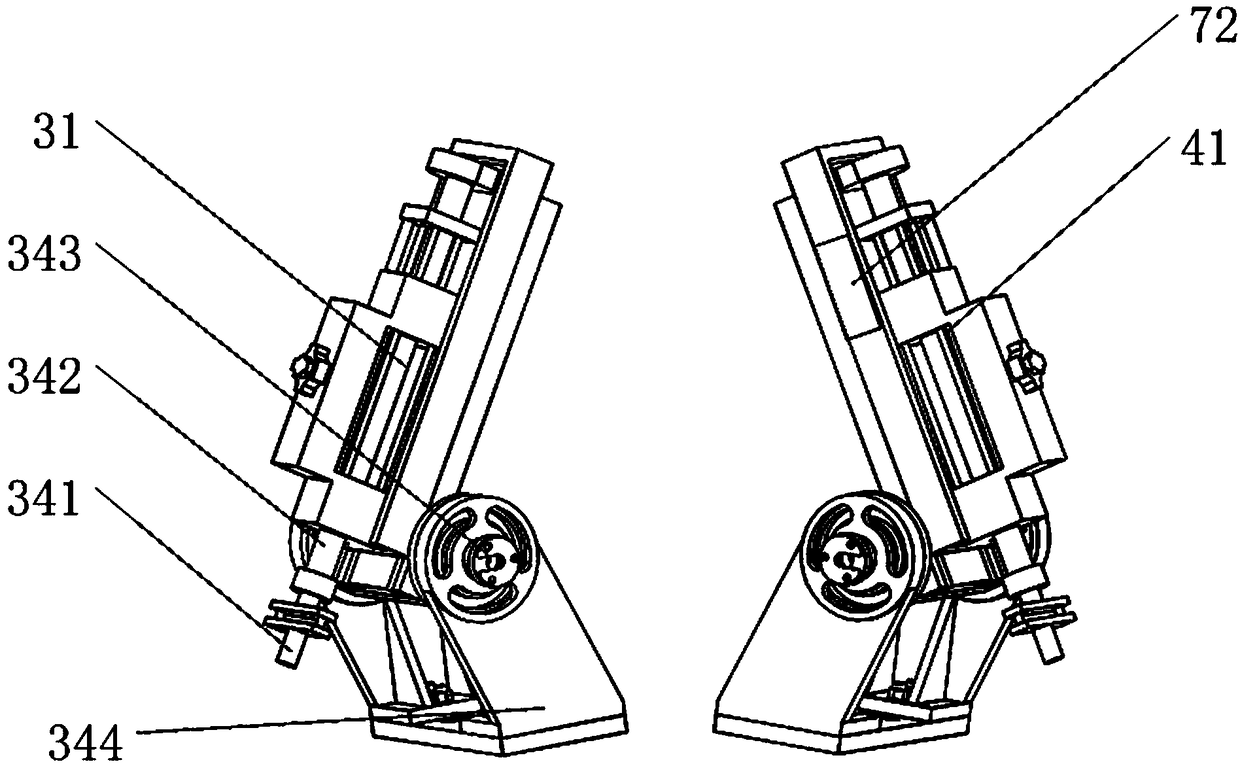

[0072] Please refer to the attached figure 1, a CNC turret tool post reliability constant speed and acceleration test device, including: horizontal iron, CNC turret tool post A1, CNC turret tool post B2, cutting force loading device A3, cutting force loading device B4, spiral lift Device 5, hydraulic station device 6 and linkage control device 7; CNC turret A1 is installed on the support device A11 of the inclined bed base; CNC turret B2 is installed on the support device B21 of the inclined bed base; the inclined bed base The supporting device A11 and the supporting device B21 of the inclined bed base are fixed on the horizontal iron; the spiral lifting device 5 is installed between the CNC turret tool post A1 and the CNC turret tool post B2; the cutting force loading device A3 and the cutting force loading device B4 is fixed on the screw lifting device 5; the hydraulic station device 6 is respectively connected with the CNC turret tool post A1 and the CNC turret tool post B2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com