XRD-based ternary composite material chip structure analysis system and method

A technology for combining material chips and structural analysis. It is applied in computer material science, pattern recognition in signals, instruments, etc. It can solve the problems of neglecting physical properties and inaccurate construction of phase diagrams, and achieves simple and convenient interactive operation and system control. Improve the effectiveness of XRD data analysis, ensure reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

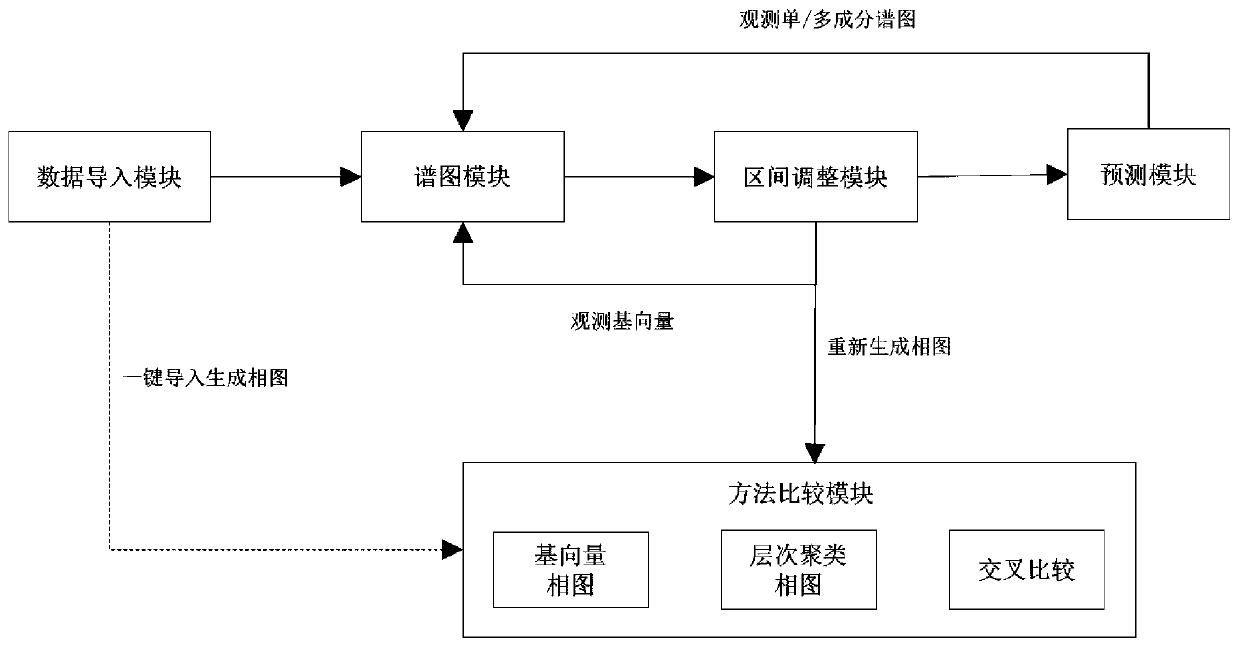

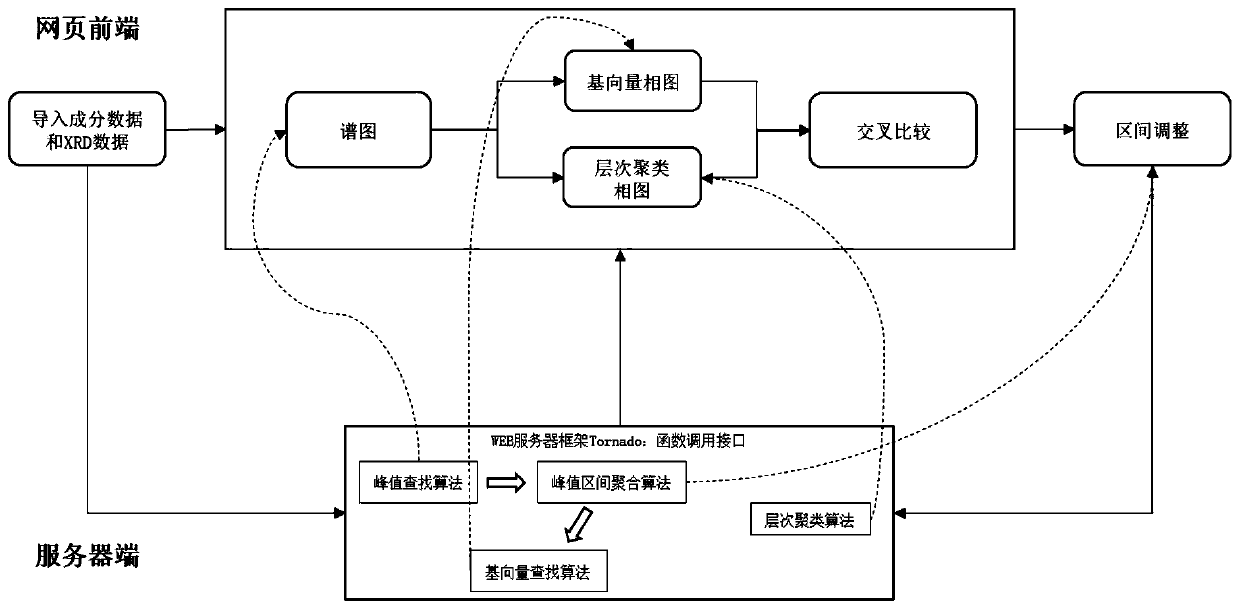

[0014] Such as figure 1 As shown, this embodiment relates to an XRD-based ternary combination material chip structure analysis system, including: a data import module for importing spectrogram coordinate component data and XRD spectral data, and a summary for displaying all spectrograms The spectrum module of the view, the prediction module that calibrates the class of each spectrum, the interval adjustment module and the method comparison module used to modify the peak interval.

[0015] The data import module is used to load coordinate composition data and XRD data, the first row of coordinate composition data needs to specify the material composition of each position, each next row represents different composition data, and the first row of XRD data represents the abscissa of the spectrum , and each next line represents different spectral data, and the two data files correspond line by line.

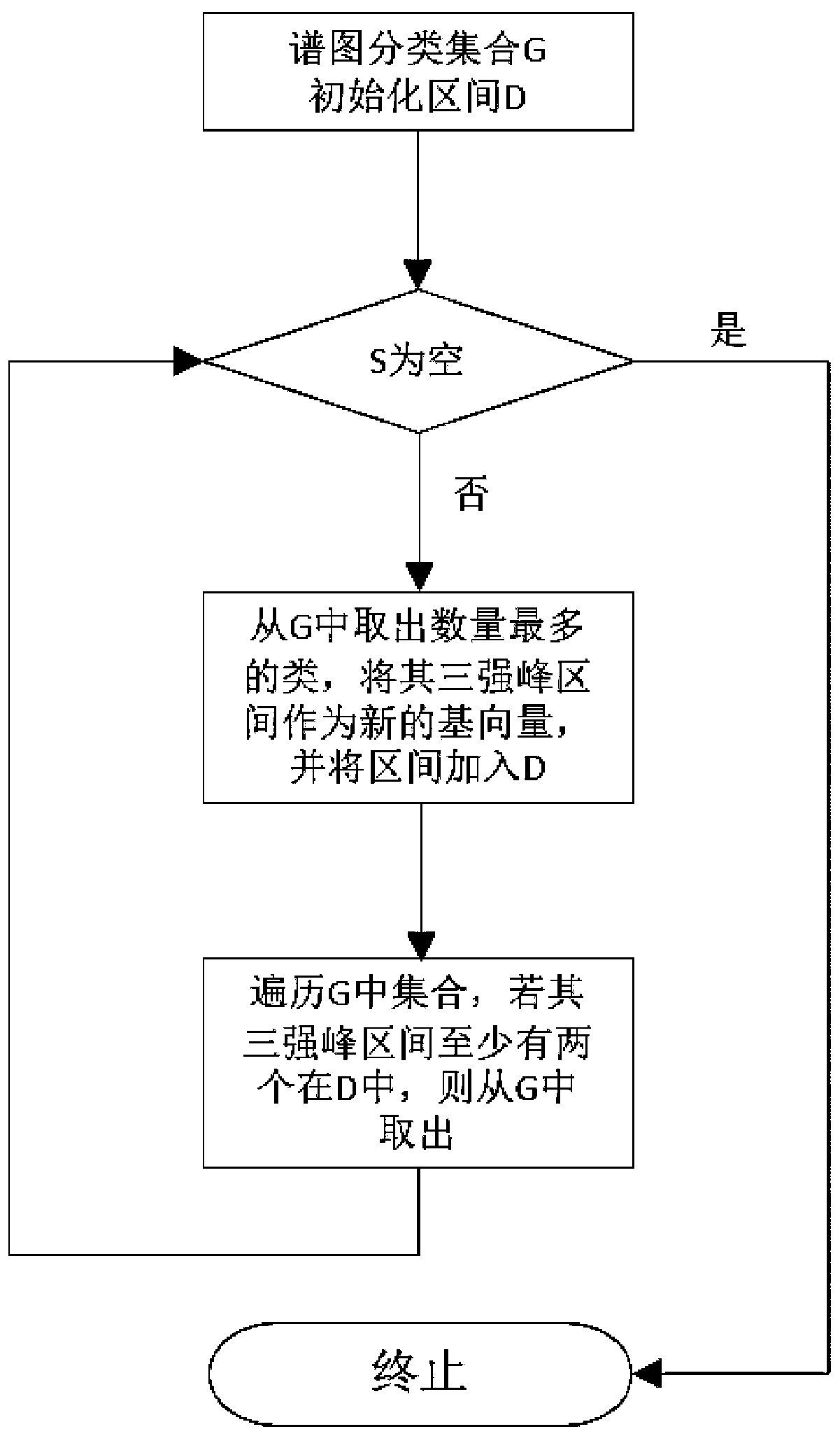

[0016] The spectrogram module displays a summary view of all spectrograms in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com