Adhesive pouring device of LED (light emitting diode) lamp

A technology of LED lights and glue filling, which is applied to the device and coating of the surface coating liquid, which can solve the problems of low degree of automation, affecting production efficiency, and poor continuity, and achieve strong continuity and structure Simplicity and the effect of improving work productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be further described in detail below in conjunction with specific examples, but the protection scope of the present invention is not limited to the following description.

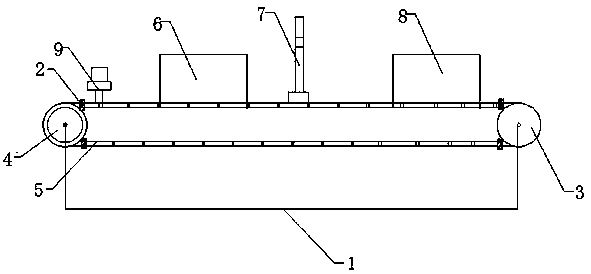

[0016] like Figure 1-2 As shown, a glue filling device for LED lamps includes a frame 1, and the two ends of the side frame of the frame 1 are equipped with a drive shaft 3 with a sprocket 2, and the sprocket 2 is provided with two The chains 5 are parallel to each other, the transmission shaft at one end is provided with a transmission gear 4 connected with the power mechanism, and the frame 1 is sequentially provided with a preheating zone 6 and a glue filling zone from one end of the transmission gear 4 7 and curing area 8, the lamp fixing base 9 is uniformly arranged on the chain 5.

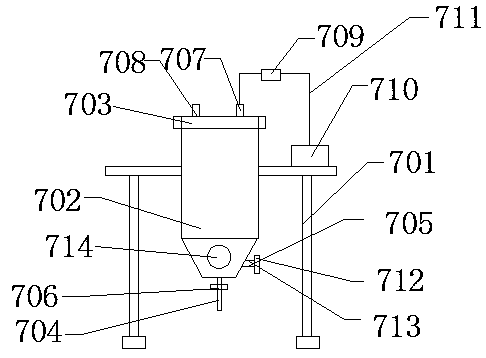

[0017] Further, the glue filling area 7 includes a support base 701 and a glue filling tank 702, the glue filling tank 702 is fixedly arranged above the support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com