Self-rope-arranging winch

A hoist and self-draining rope technology, which is applied to hoisting devices and clockwork mechanisms, can solve problems such as no direction of the rope, and achieve the effects of stable pulley movement, orderly placement, and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

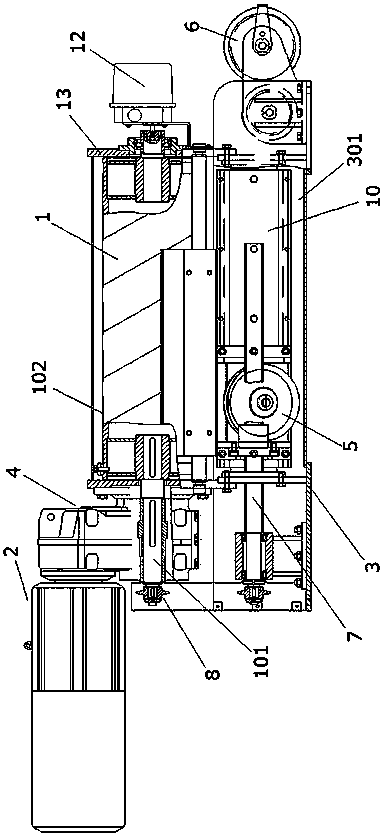

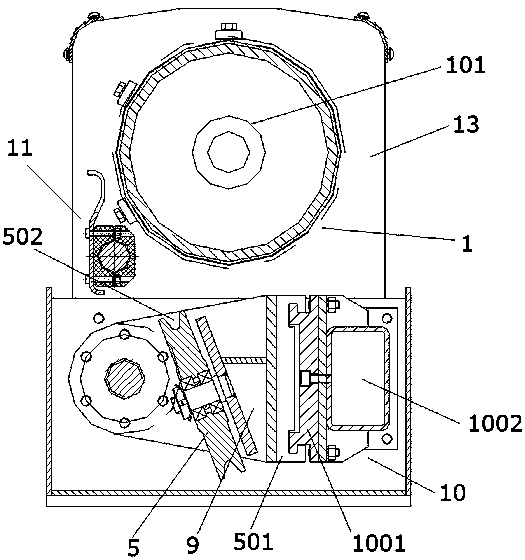

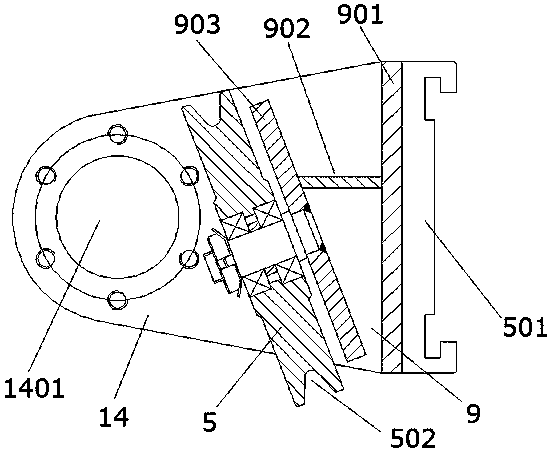

[0028] Such as figure 1 Shown is the self-draining rope winch of the present invention, including a reel 1, a motor 2 and a base 3, the motor 2 is connected with a speed reducer 4, and the reel 1 is installed on the base 3; The machine 4 is connected with the reel shaft 101 of the reel 1 to drive the reel 1 to rotate; there is a pulley 5 under the reel 1, and the pulley 5 moves along the axial direction of the reel 1; The radial section of the pulley 5 is perpendicular to the radial section of the reel 1, and forms an included angle of 21 degrees with the axial section of the reel 1 (it can also be any angle between 10-40), such as figure 2 As shown; also includes a rope guide wheel 6, the rope guide wheel 6 is arranged on the base 3, and the wire rope is discharged from the reel 1 and is discharged by the rope guide wheel 6 after winding around the pulley 5 ; Both ends of the reel 1 have a vertical plate 13, and the end of the reel shaft 101 is flush with the outer surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com