Shield hob transport track

A technology of transportation track and shield hob, which is applied in underground transportation, transportation and packaging, tunnels, etc. It can solve the problems that affect the construction progress, time-consuming and labor-intensive, and achieve the effect of speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the drawings and specific embodiments.

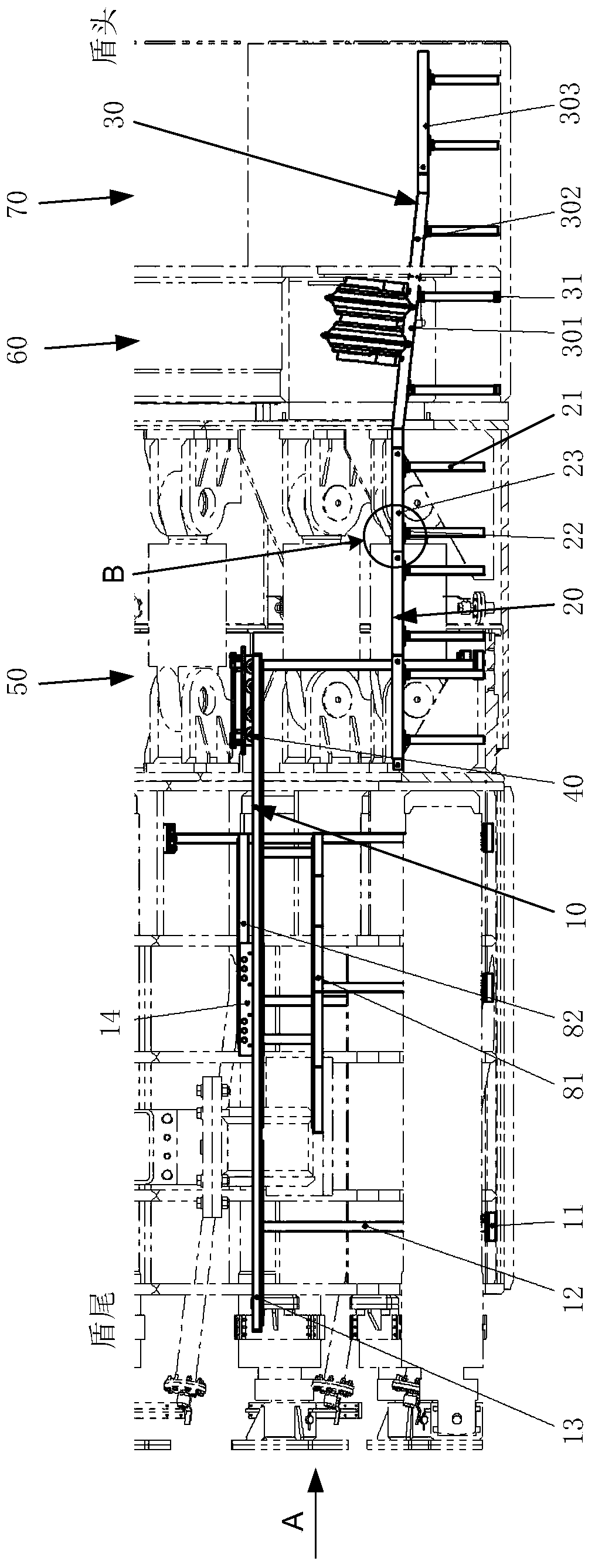

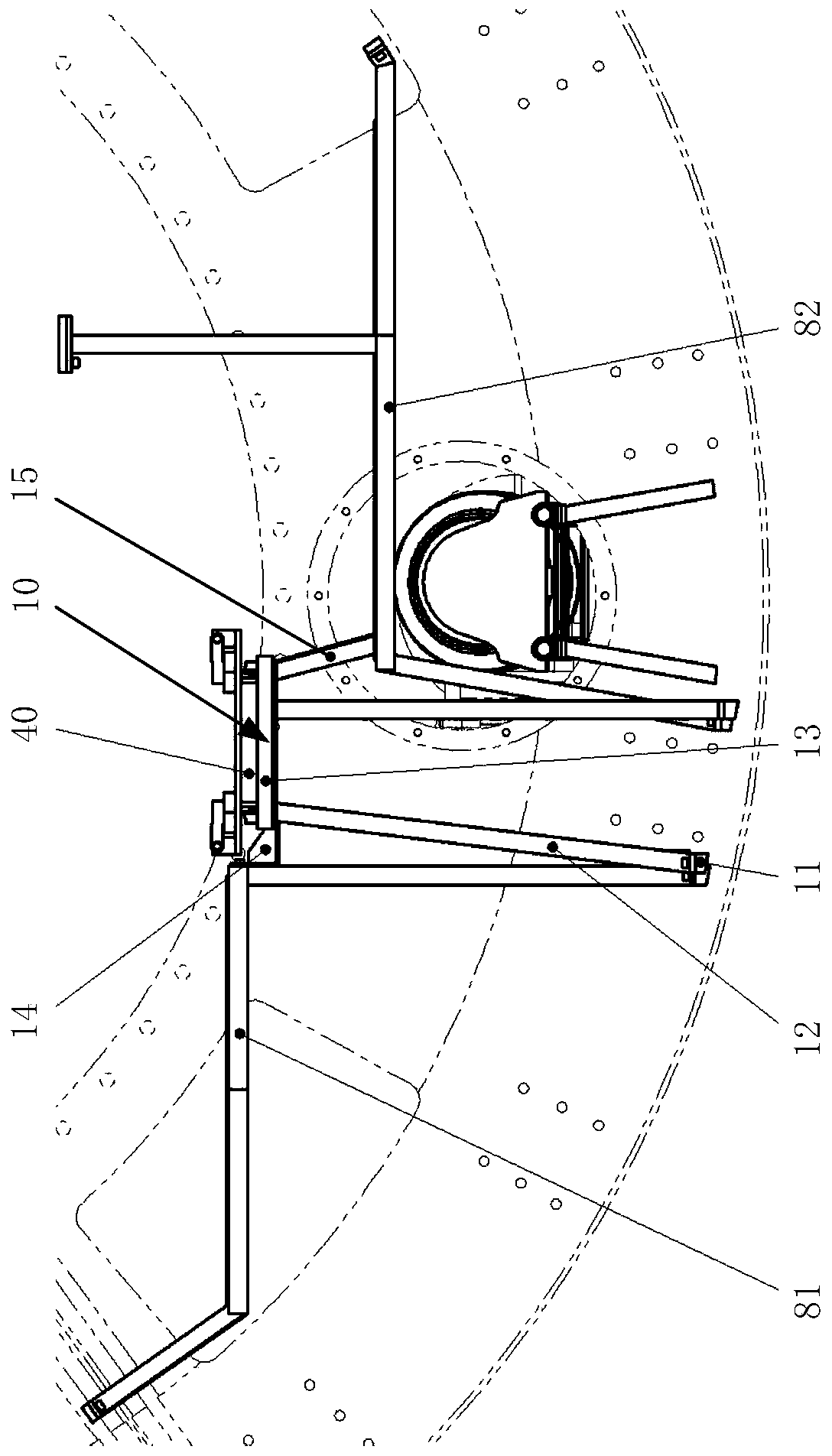

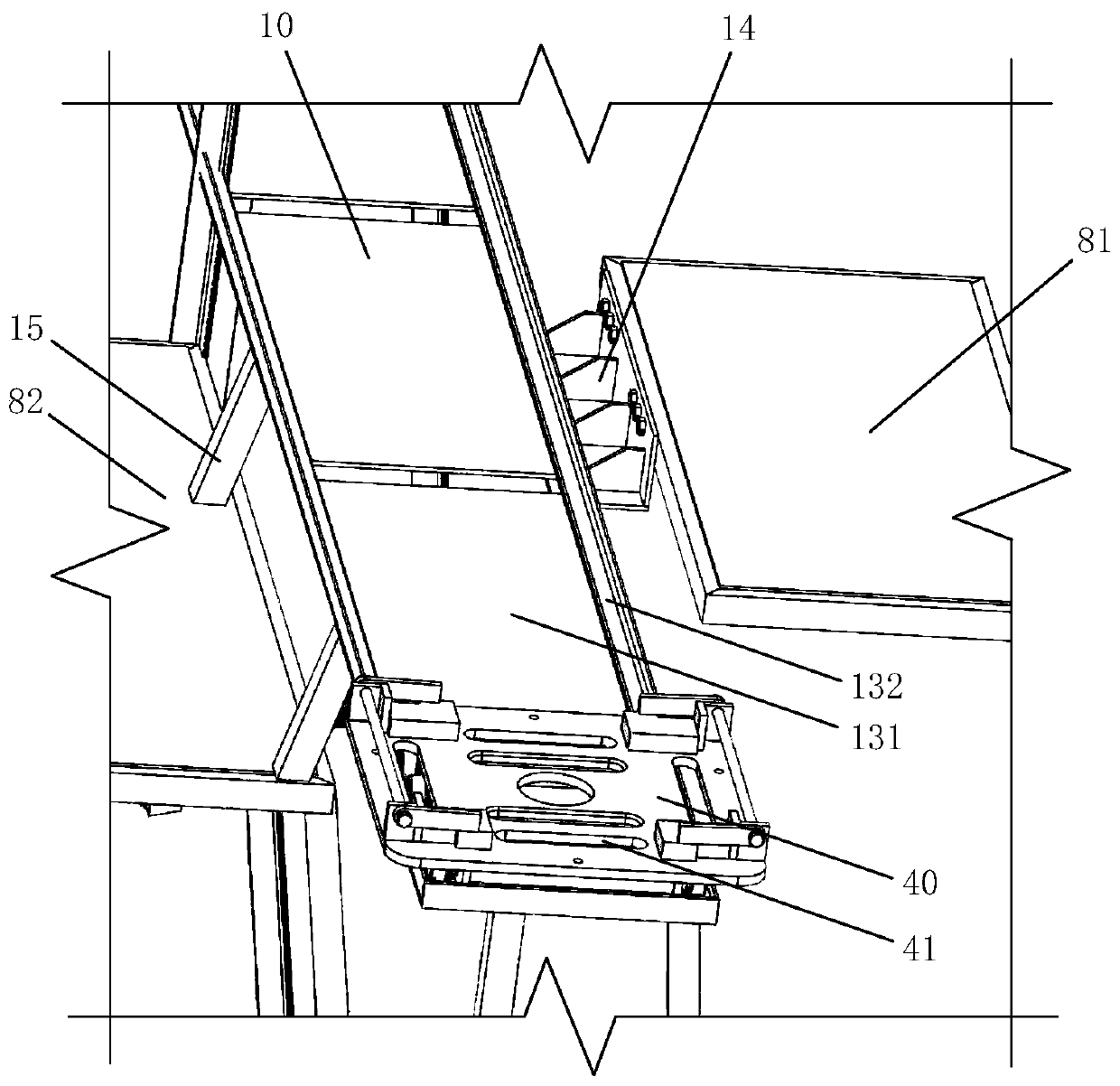

[0023] Refer to figure 1 The present invention provides a shield hob transport track, which does not need to be completely dismantled when the shield is advancing, and achieves the effects of saving manpower and speeding up the construction progress. The following describes the shield hob transport track of the present invention with reference to the accompanying drawings.

[0024] Such as figure 1 As shown, the shield hob transport track of the present invention includes a track set connected and supported on the shield shell, and the track set passes through the belt conveyor in the shield shell at the tail of the shield along the lower left of the shield advancing direction, and the cutter head The lower part of the drive 50 and the transition compartment 70 continuously extend from the tail of the shield to the head of the shield, so that the hob can be tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com