Multifunctional Welding Test Specimen Fixture

A welding test and multi-functional technology, applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of single angle clamping, etc., to avoid the operation space, ensure the accuracy, and avoid the effect of test shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below through specific examples.

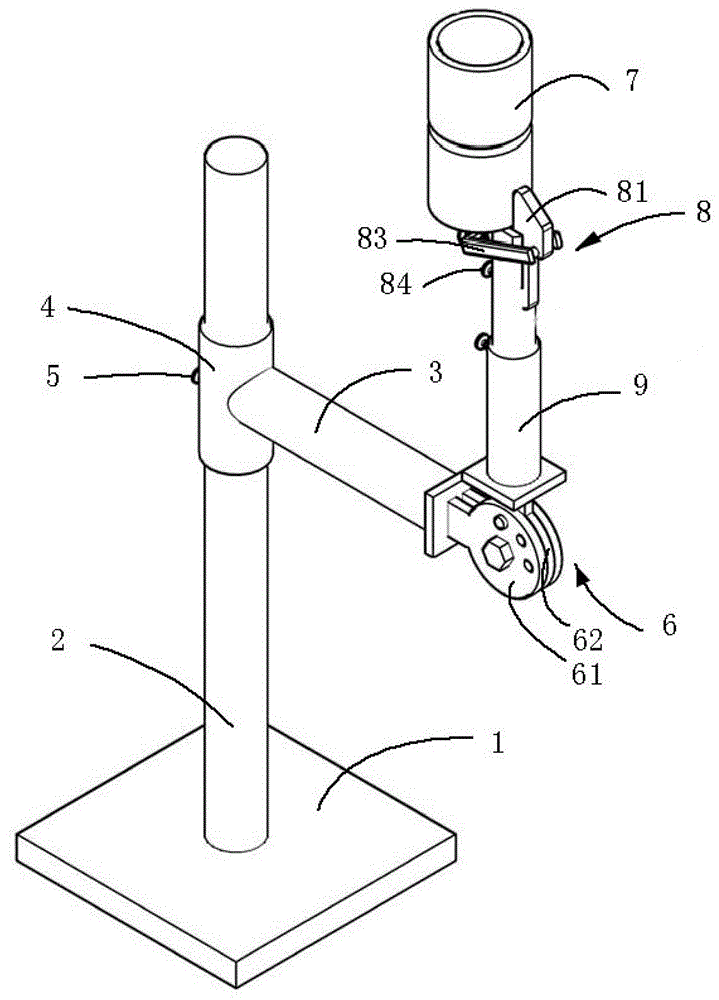

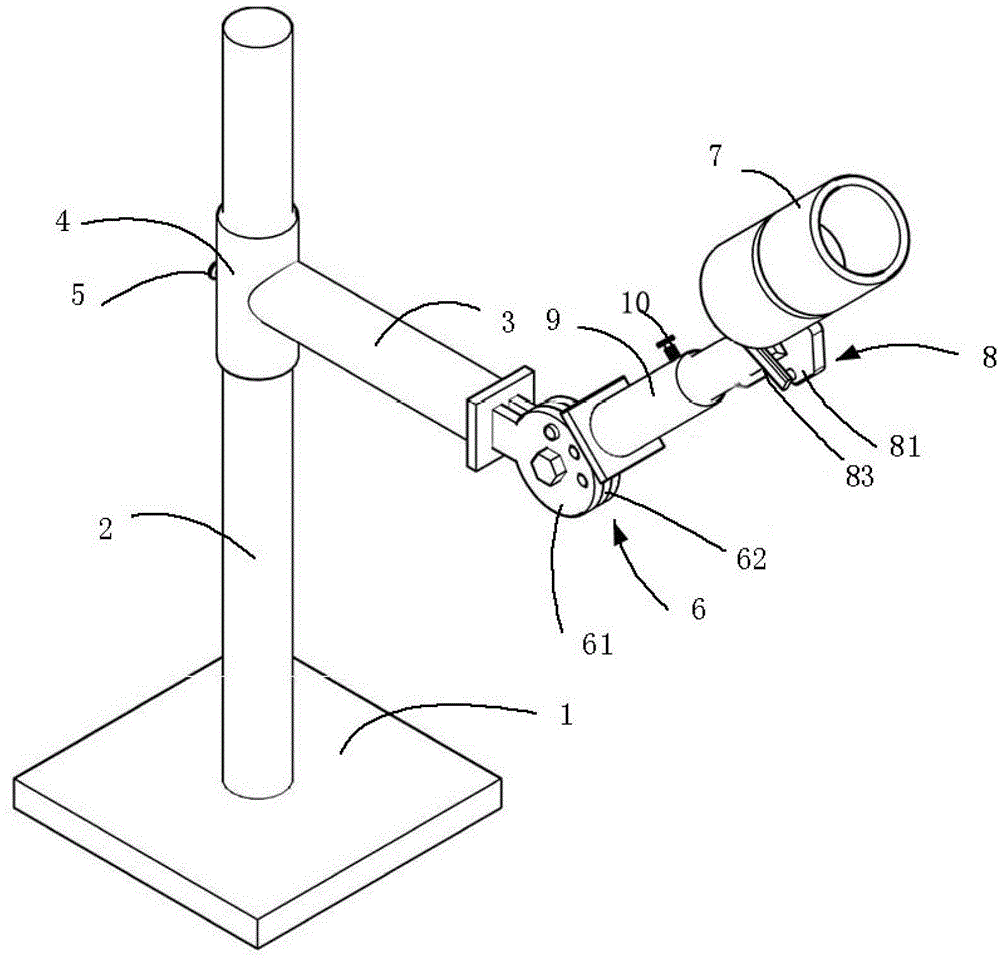

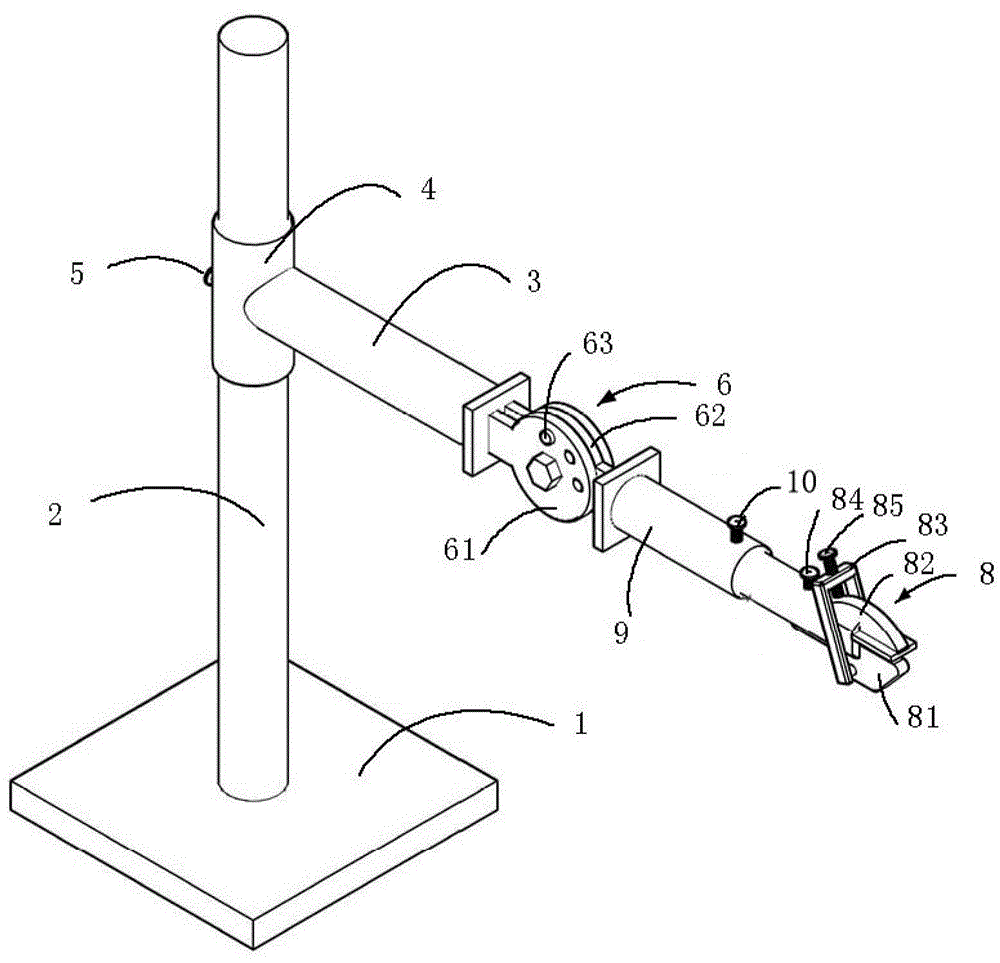

[0031] Such as Figure 1-4 As shown, the multifunctional welding test specimen 7 fixtures include a base 1, a column 2, a beam 3, a movable cantilever 9 and a clamp 8, the column 2 is fixed on the base 1, and the beam 3 is installed on the column 2, In this embodiment, one end of the crossbeam 3 is provided with a sleeve 4, and the sleeve 4 is set on the outside of the column 2 and fixed by the positioning bolt 5. The crossbeam 3 is perpendicular to the sleeve 4, that is, the crossbeam 3 is horizontal, so One end of the movable cantilever 9 is hinged with the crossbeam 3, an angle adjustment mechanism 6 for adjusting the angle between the movable cantilever 9 and the crossbeam 3 is provided between the movable cantilever 9 and the crossbeam 3, and the chuck 8 is installed on the movable cantilever 9 another side.

[0032] Described angle adjustment mechanism 6 comprises a pair...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com