Injection molding machine pressure-maintaining system and injection molding machine

An injection molding machine and pressure maintaining technology, which is applied to the injection molding machine pressure maintaining system and the field of injection molding machines, can solve problems such as inaccurate judgment of the timing of pressurization, and achieve the effect of solving the inaccurate judgment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

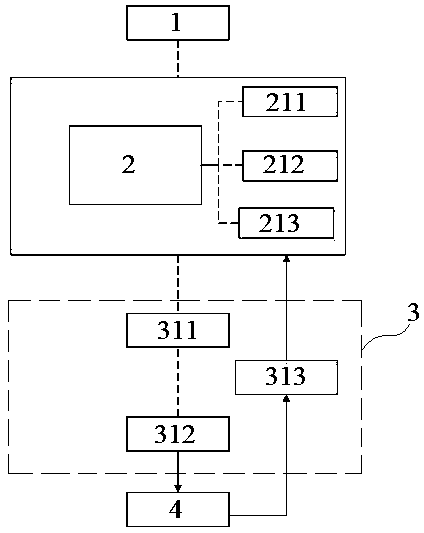

[0027] Specific embodiment 2 of the injection molding machine of the present invention, the pressure maintaining system of the injection molding machine in this embodiment includes a timing device, and the timing device transmits the timing to the information processing system, and the information processing system controls the pressurization unit according to the information transmitted by the timing device. Timing of pressurization of the mixing device. The embodiment of the information processing system and the pressurizing unit in this embodiment is the same as the embodiment of the information processing system and the pressurizing unit in Embodiment 1, and will not be repeated here.

specific Embodiment 3

[0028]Specific embodiment 3 of the injection molding machine of the present invention, the pressure maintaining system of the injection molding machine in this embodiment includes a liquid level gauge and an information processing device connected to the liquid level gauge. The information is transmitted to the information processing system, and the information processing system controls the pressurizing unit to pressurize and maintain the pressure of the mixing device. The embodiment of the information processing system and the pressurizing unit in this embodiment is the same as the embodiment of the information processing system and the pressurizing unit in Embodiment 1, and will not be repeated here.

[0029] The embodiments of the pressure maintaining system of the injection molding machine of the present invention are the same as the embodiments of the pressure maintaining system of the injection molding machine in the above-mentioned embodiments of the injection molding m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com