Transport device for fabricated wall and transport method thereof

A transportation device and assembly technology, applied in the direction of transportation and packaging, packaging, external accessories, etc., can solve the problems of easy bump damage to the wall, failure to protect the wall, troublesome installation, etc., to avoid bump damage, simple structure, and easy installation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

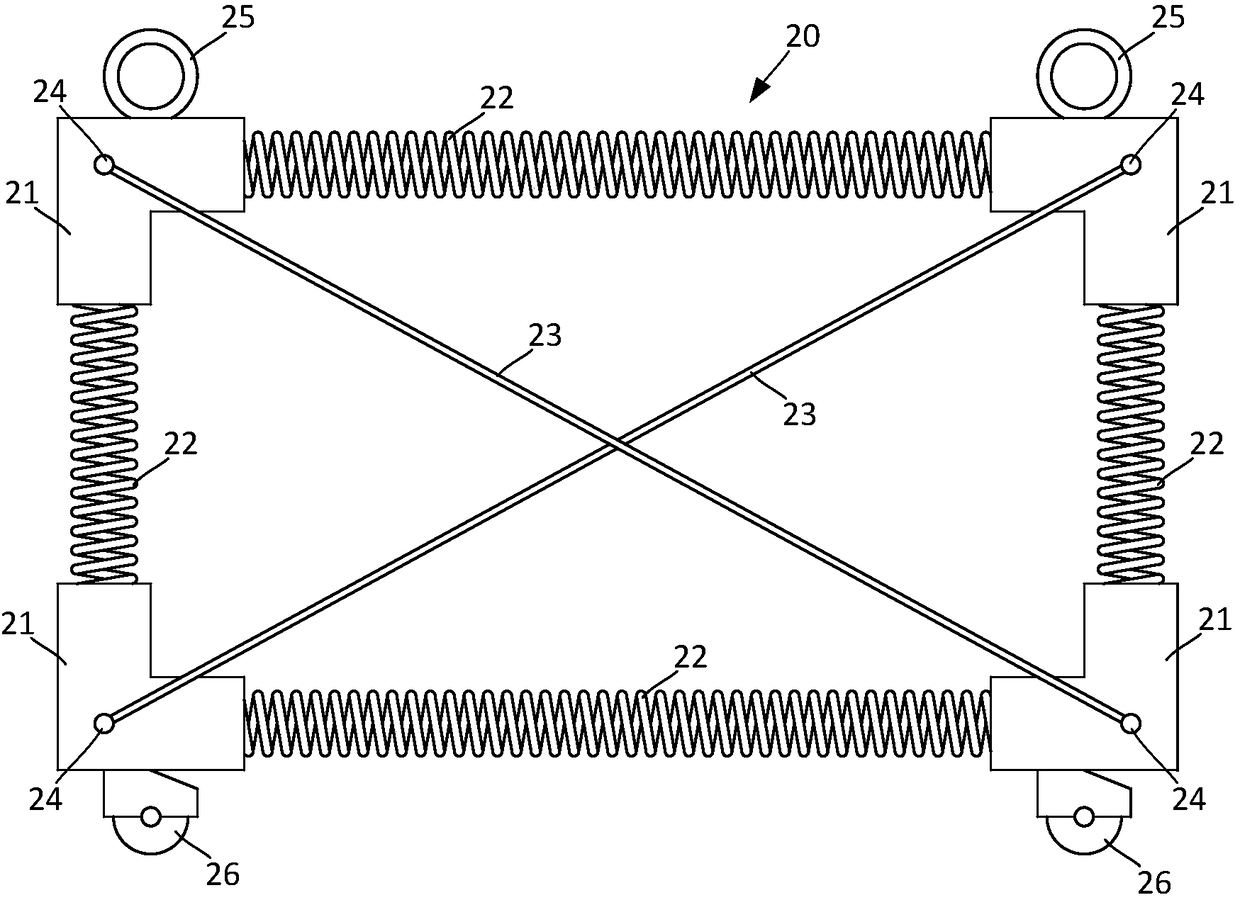

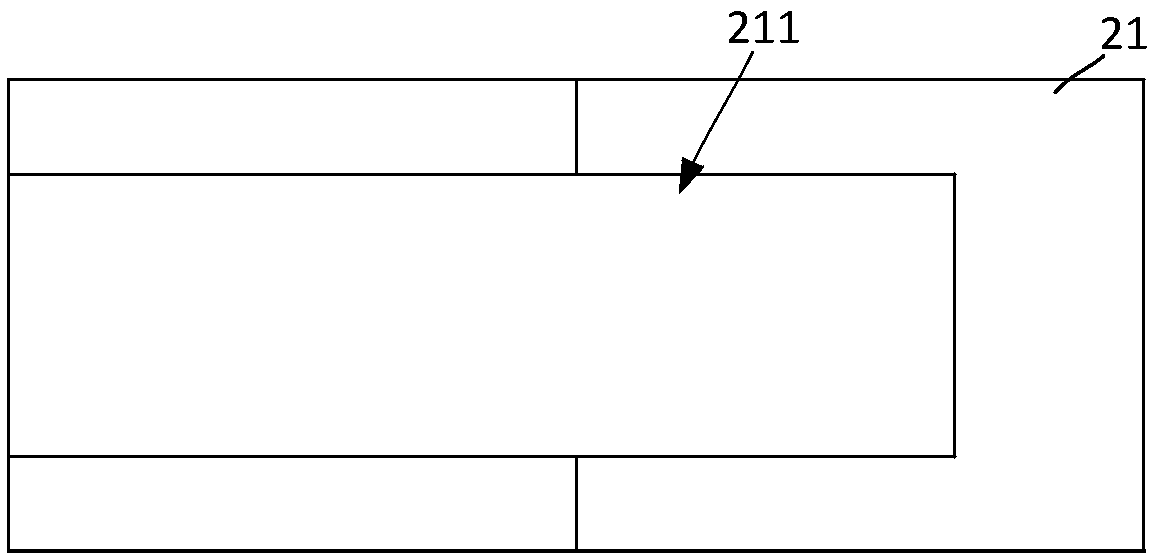

[0028] refer to figure 1 , the present invention provides a transport device and a transport method for a prefabricated wall, which can effectively protect the prefabricated wall and can also transport the prefabricated wall. The transport device can stretch the elastic tie The four corner-wrapping structures are set on the four corners of the prefabricated wall, and the corner-wrapping structure can be tightly wrapped around the prefabricated wall through the tension of the elastic tie. The flexible layer set on the corner-wrapping structure is The prefabricated wall plays a good protective role, and the elastic limiters tied on the diagonal wrapping structure and arranged on both sides of the prefabricated wall can improve the stability of the transportation device. In addition, the lifting ring can be used to cooperate with the crane to lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com