Prefabricated prestressed concrete stair

A concrete and prestressed technology, applied in the direction of stairs, stepped structures, buildings, etc., can solve the problems of the dead weight of the stairs, the height of the ribbed beam and the beam, and reduce the beam height, the dead weight, the deflection and the crack. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to better understand the above-mentioned technical solution of the present invention, a further detailed description will be given below in conjunction with the accompanying drawings and embodiments.

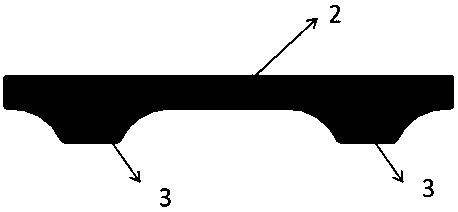

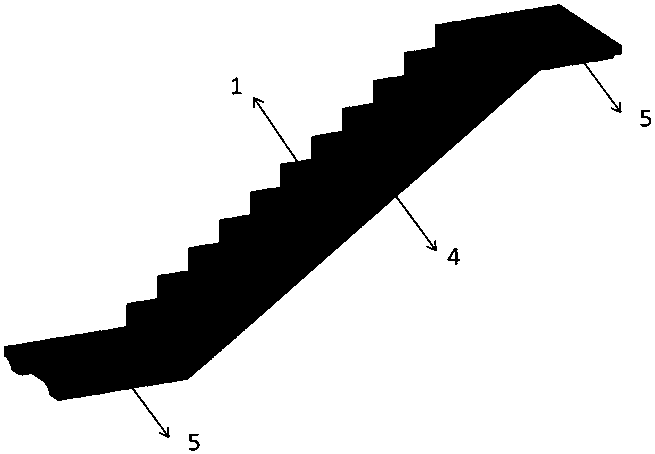

[0010] Such as figure 1 and figure 2 As shown, the prefabricated prestressed concrete stairs include stair treads 1, stair treads 2 and ribbed beams 3 under the stair treads 2, the stair treads 2 are composed of inclined ladder sections 4 and platform sections 5, and the ribbed beams 3 are equipped with prestressed rebar.

[0011] The ribbed beams 3 may be two symmetrically arranged, or one or more ribbed beams in the middle. It only needs to meet the load and force requirements of the stairs.

[0012] The combination of inclined ladder section 4 and platform section 5 is determined according to actual engineering, and the quantity is not limited. It can be freely combined by a plurality of inclined ladder segments 4 with different slopes and a plurality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com