Dynamic braking control method for electronic expansion valve

A technology of electronic expansion valve and brake control, which is applied in the direction of electric controllers and controllers with specific characteristics, and can solve problems such as large overshoot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

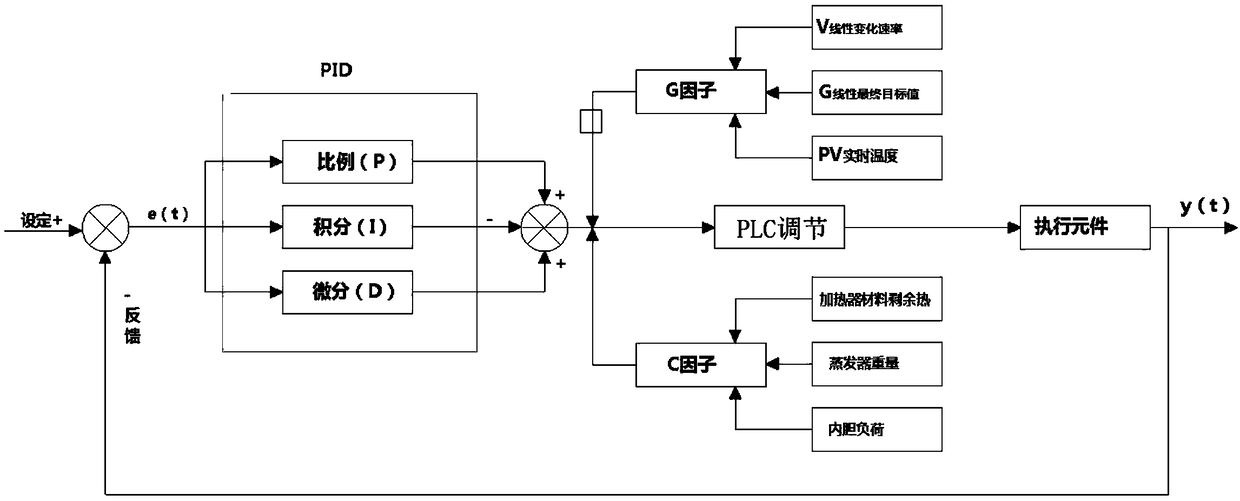

[0023] see figure 2 The present invention shows a dynamic braking control method for an electronic expansion valve, which includes the following steps:

[0024] 1) setting e(t) , and perform the PID operation of the continuous function;

[0025] 2) Set G factor, G factor includes V linear change factor, G linear final target value, PV real-time temperature;

[0026] 3) Set the C factor, which includes the residual heat of the heating material, the weight of the evaporator, and the load of the inner tank;

[0027] 4) set e(t) , after the PID calculation of the continuous function, it is substituted into the PLC system for PID adjustment of the analog quantity; at the same time, the G factor and C factor are substituted into the real-time PLC error elimination adjustment, and then the overshoot is kept within the standard by executing the original output;

[0028] 5) At the same time, the output data is fed back to e(t) .

[0029] The G factor is specifically: when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com