Telescopic type size variable continuous type robot

A scale-variable and continuous technology, applied in the field of robotics, can solve the problems of few longitudinal dimensions and free changes of manipulators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

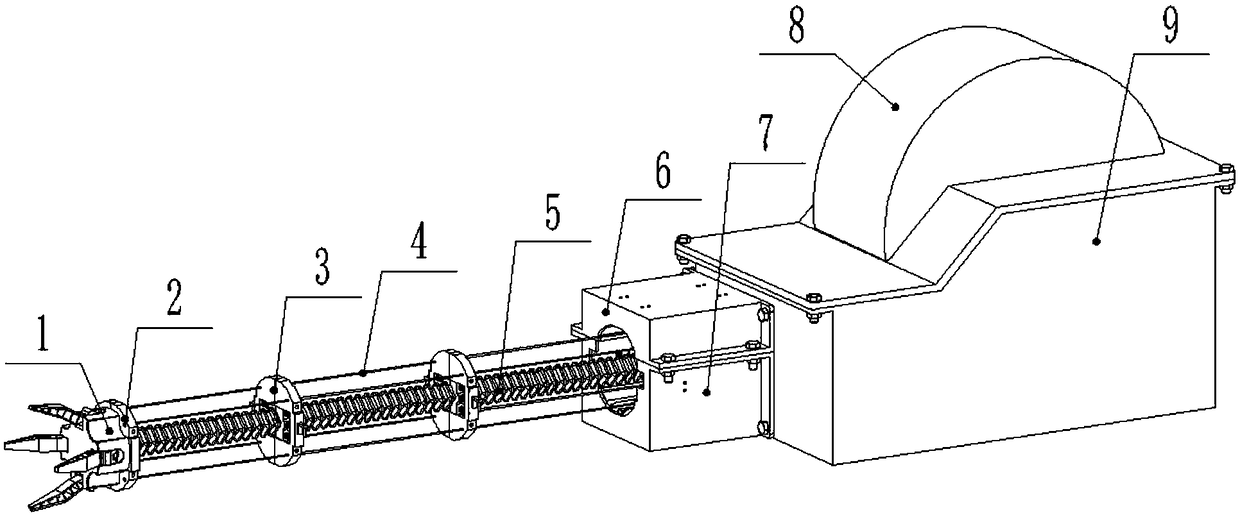

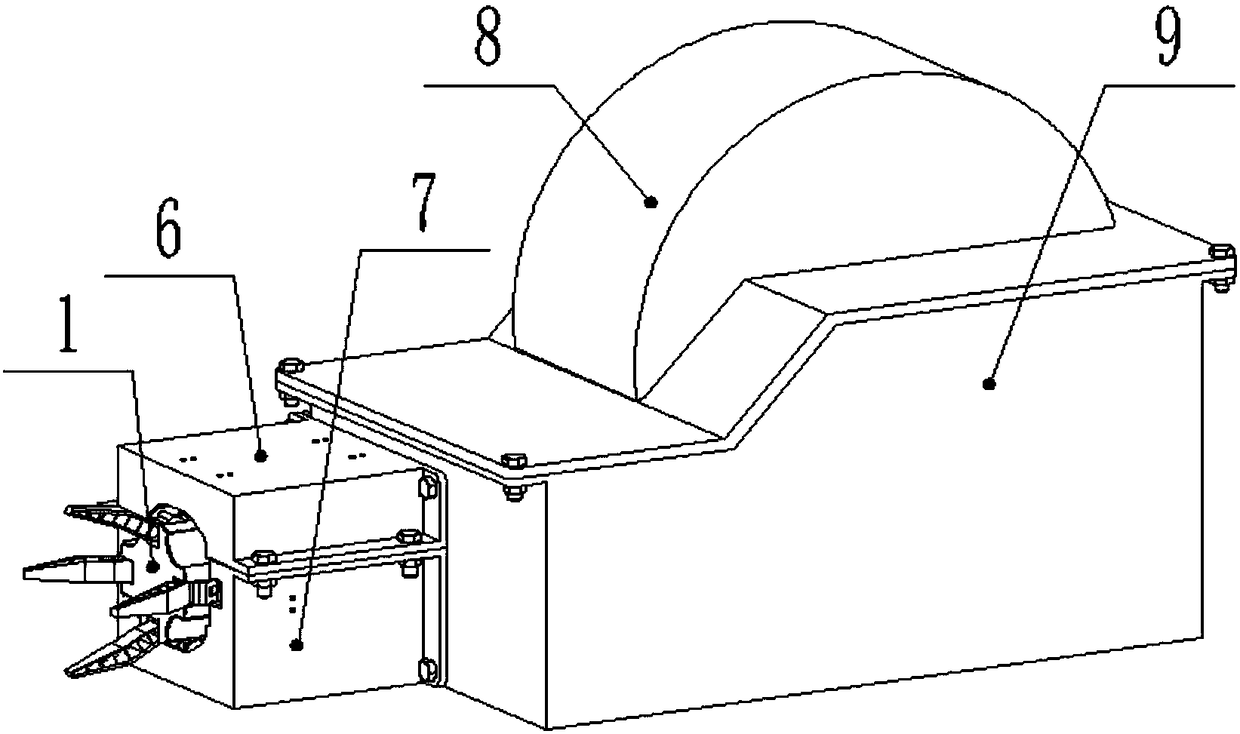

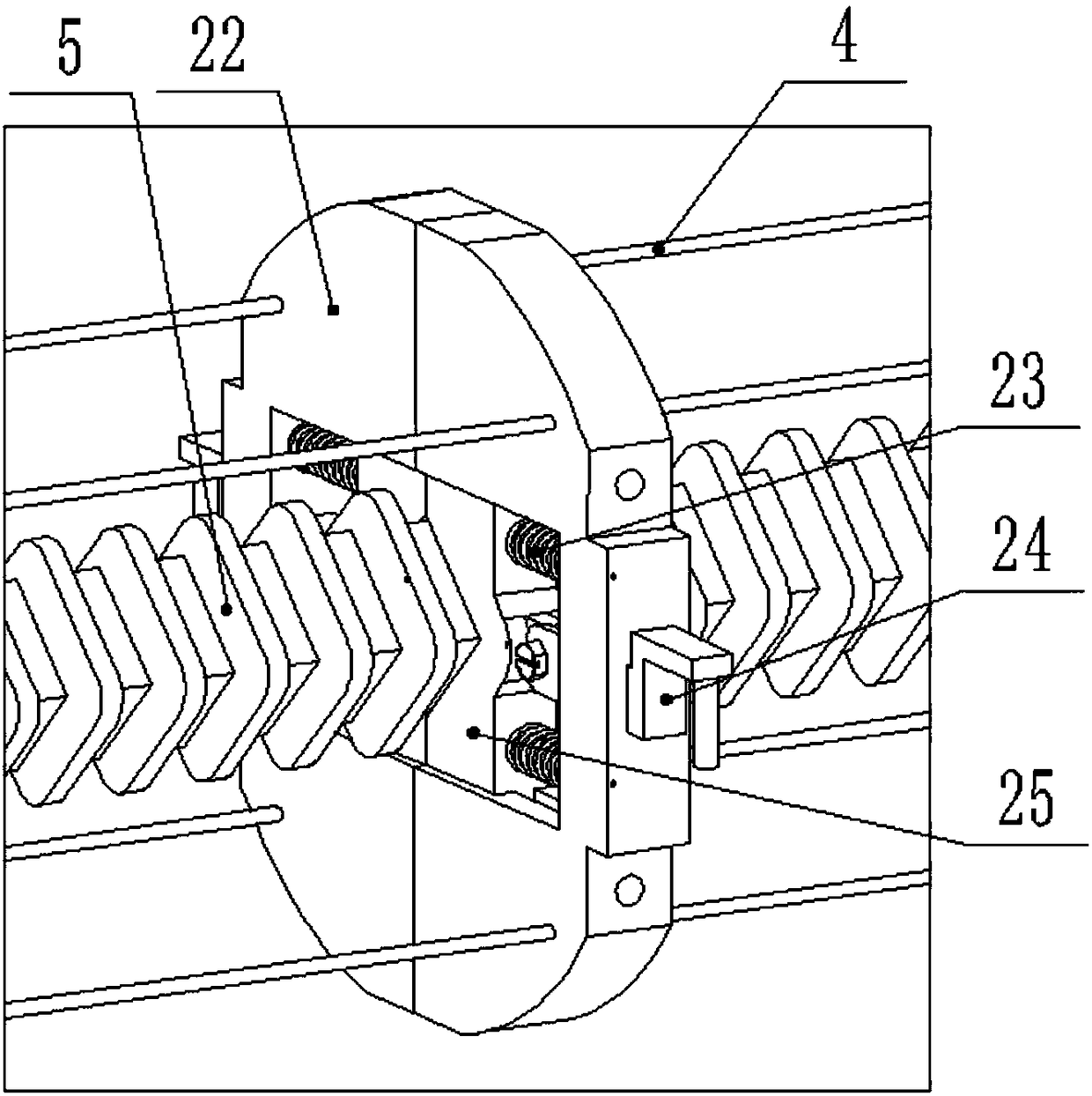

[0027] exist figure 1 and figure 2 In the shown schematic diagram of the telescopic variable-scale continuous robot, the box body includes a main box body and a storage box body, and the side wall (front side wall) of the main box body 9 provided with the main box cover 8 is provided with a through hole. The outer wall of the through hole is provided with a storage box connected to it by a storage box 7 and a storage box cover 6. The storage box and the storage box cover are not only connected up and down but also connected with the main box respectively. The body and the storage box cover are not provided with the main box body to establish through hole side walls adjacent but parallel walls (front side walls) are respectively provided with upward and downward opening grooves, and the two opening grooves are relatively circular through holes. The box is provided with a driving mechanism, a guiding mechanism, a storage mechanism, a flexible mechanical arm and an end effector...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com