Integration device for solenoid valve assembling

A technology of integrated device and solenoid valve, applied in the direction of coupling device, connecting device components, circuits, etc., can solve the problems of high assembly error rate, poor dustproof effect of integrated valve seat, etc., and achieve the effect of reducing the error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Before the present invention is described in detail, it should be noted that in the following description, similar components are denoted by the same numerals.

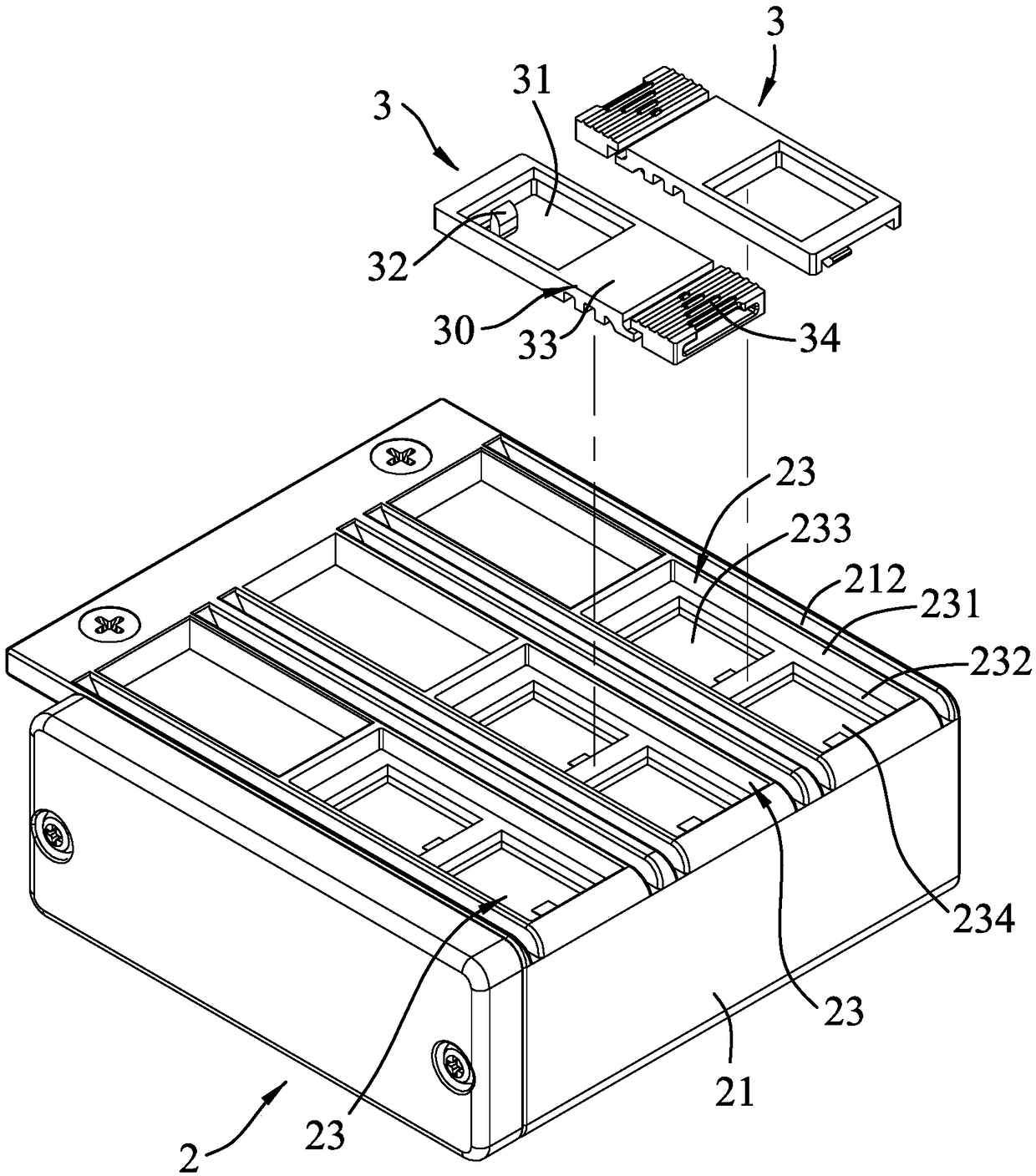

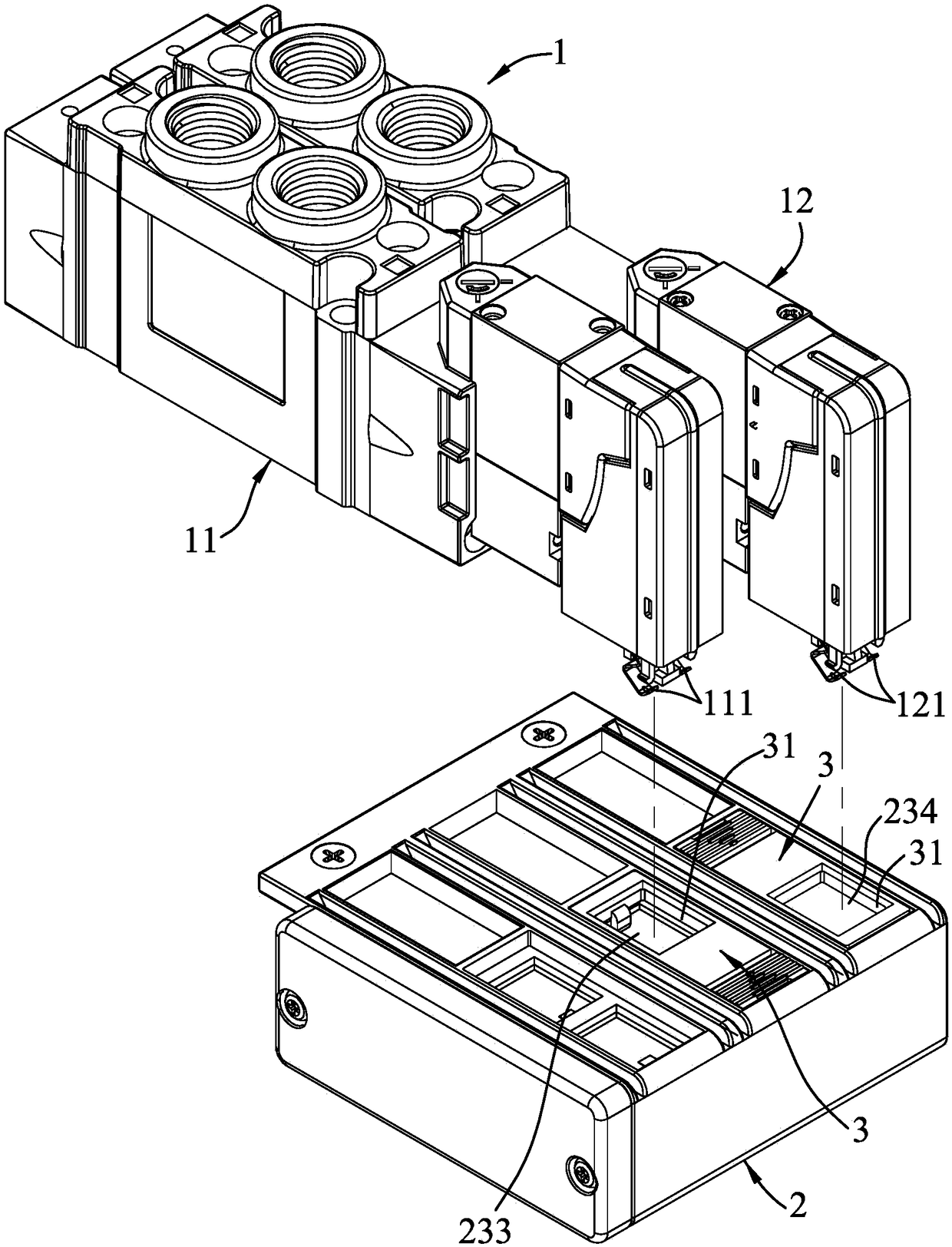

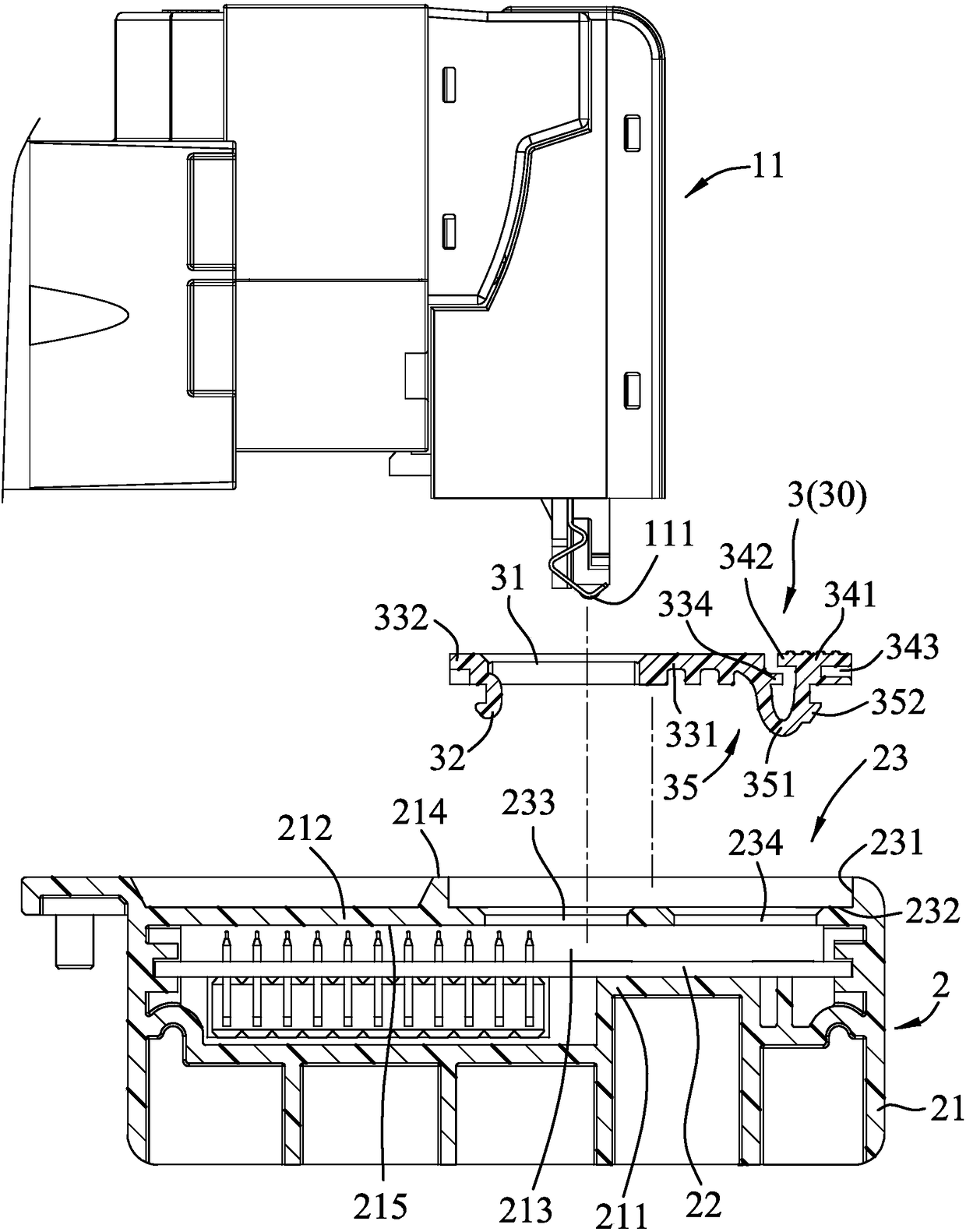

[0027] refer to figure 1 , 2 , a first embodiment of the integrated device of the present invention can be electrically connected with a solenoid valve group 1, the solenoid valve group 1 has a first solenoid valve 11 with a two-position structure, and a second solenoid valve with a three-position structure 12. The first solenoid valve 11 and the second solenoid valve 12 are long rectangular bodies, but have different lengths due to different internal structures. The first solenoid valve 11 has a pair of first pins 111 protruding downward , the second solenoid valve 12 has a pair of second pins 121 protruding downwards and having a position difference from the first pins 111 . The form of the electromagnetic valve group 1 suitable for assembly on the integrated device of this embodiment is not particularly li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com