Method for manufacturing hollow article

一种制造方法、中空的技术,应用在中空物品、其他家里用具、家里用具等方向,能够解决制造工序妨碍等问题,达到前置时间缩短、数目均匀的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

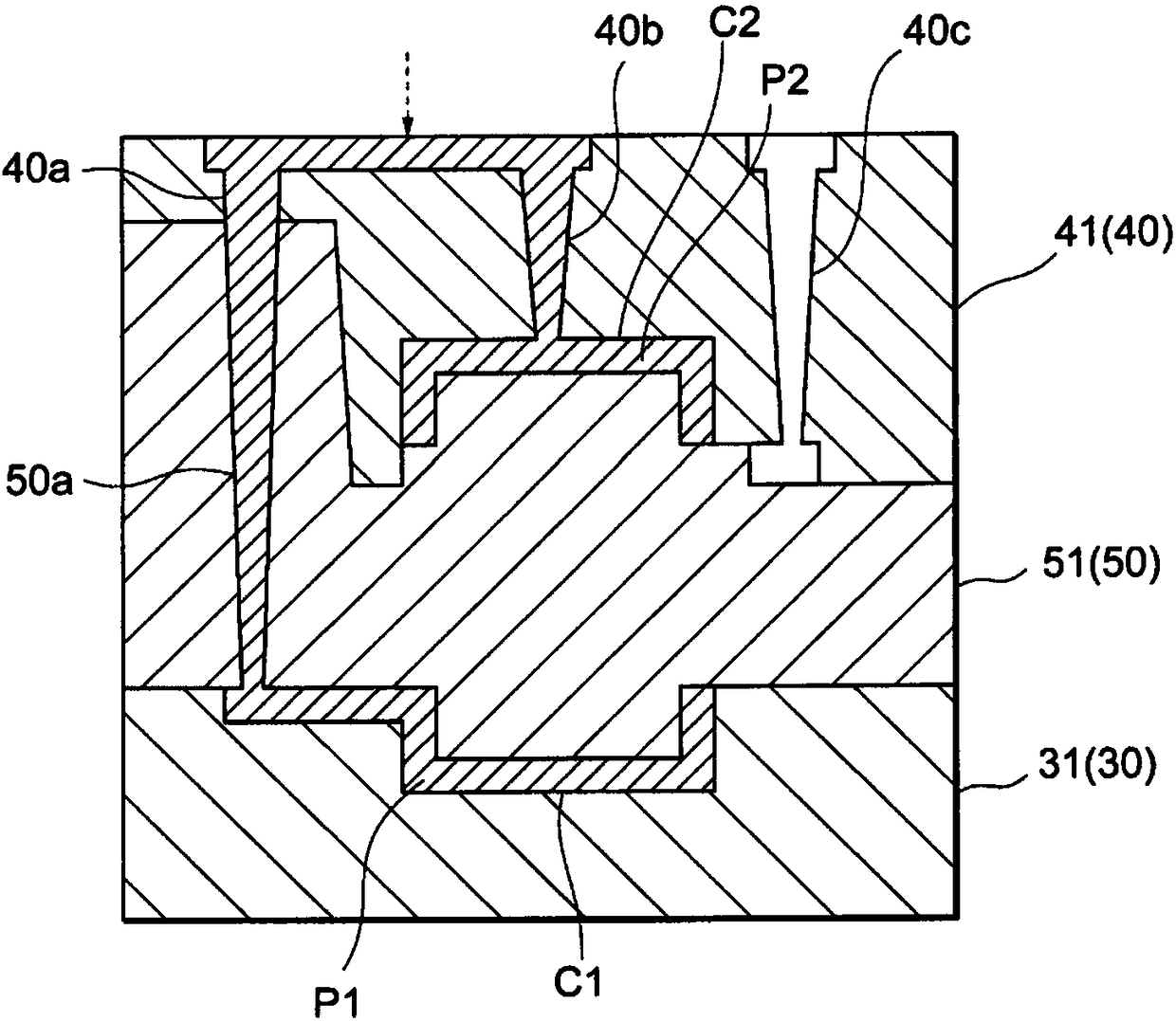

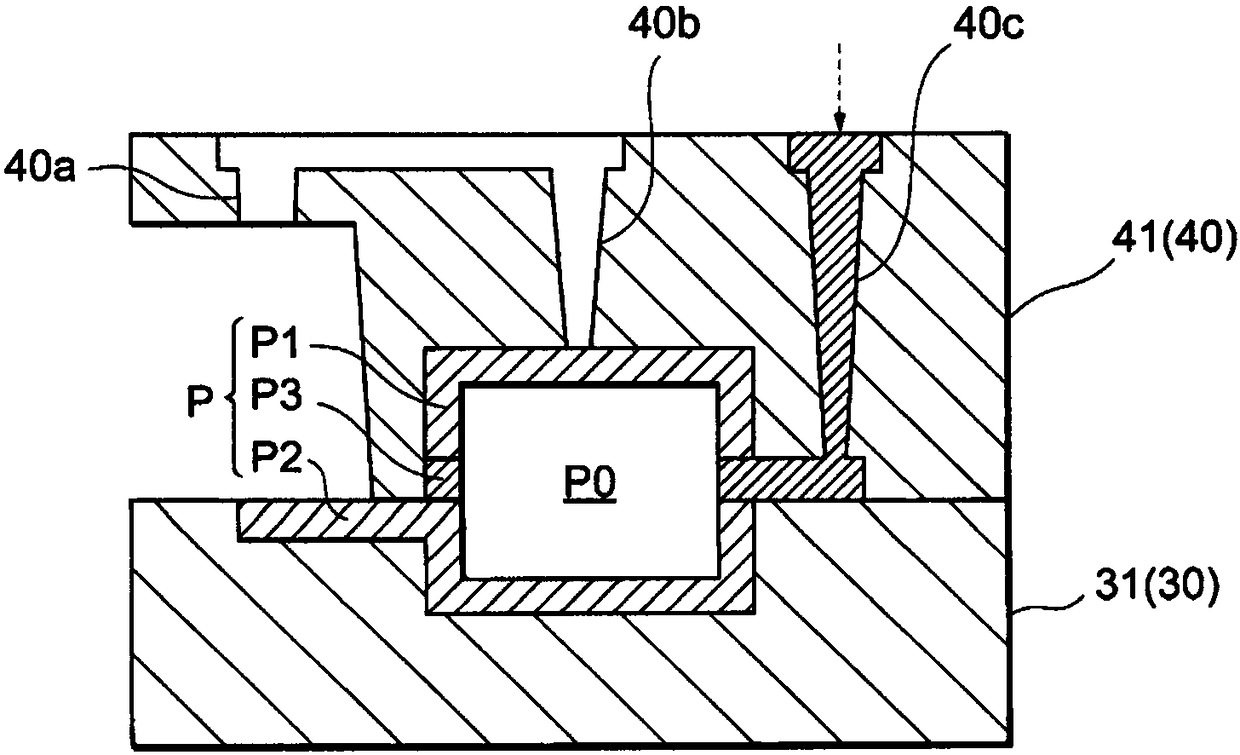

[0031] refer to figure 1 ˜ FIG. 7 , the manufacturing method according to the first embodiment will be described. This manufacturing method is a method of manufacturing the hollow product P mentioned later. The hollow product P is a member in which a space P0 is formed. The hollow product P uses an air flow meter for measuring the flow rate of air, and the air to be measured flows inside.

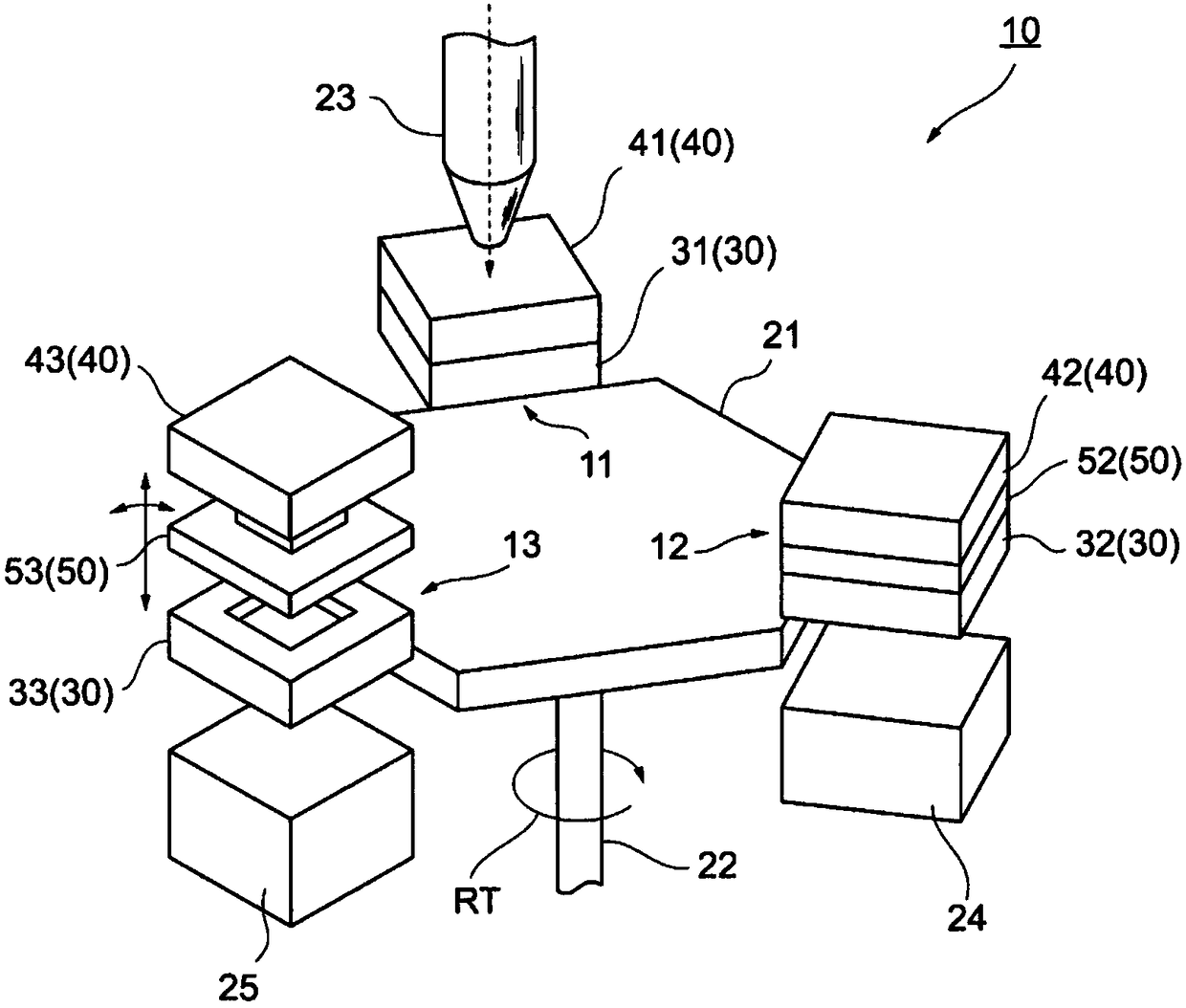

[0032] figure 1 It is a perspective view which shows the molding apparatus 10 used for the manufacturing method which concerns on this 1st Embodiment. The forming device 10 has a table 21 , a nozzle 23 , three sets of movable dies 30 and fixed dies 40 , and two inner dies 50 .

[0033] The table 21 is a flat member whose thickness direction is a vertical direction. A rotation shaft 22 extending vertically is provided at the lower portion of the table 21 . The rotary shaft 22 rotates in the direction shown by the arrow RT by the drive of the actuator not shown, and the table 21 also ro...

no. 2 approach

[0106] Next, refer to Figure 8 , Figure 9A as well as Figure 9BThe manufacturing method according to the second embodiment will be described. The manufacturing method according to the second embodiment is the same as the manufacturing method according to the first embodiment. First, the pair of split bodies are formed, and then the pair of split bodies are joined to form a hollow product. The manufacturing method according to the second embodiment uses a molding apparatus 100 different from the molding apparatus 10 used in the manufacturing method according to the first embodiment. The same reference numerals are assigned to the same configurations of the molding apparatus 100 as those of the molding apparatus 10 as appropriate, and description thereof will be omitted.

[0107] Figure 8 It is a perspective view showing the forming apparatus 100 used in the manufacturing method according to the second embodiment. The forming apparatus 100 has a table 21 , a nozzle 23 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com