Sectioned well cementation technology for deep trona drilling and mining

A trona and cementing technology, which is applied in earth-moving drilling, wellbore/well components, sealing/packing, etc. The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will be described in detail in conjunction with the technical solutions in the embodiments of the present invention:

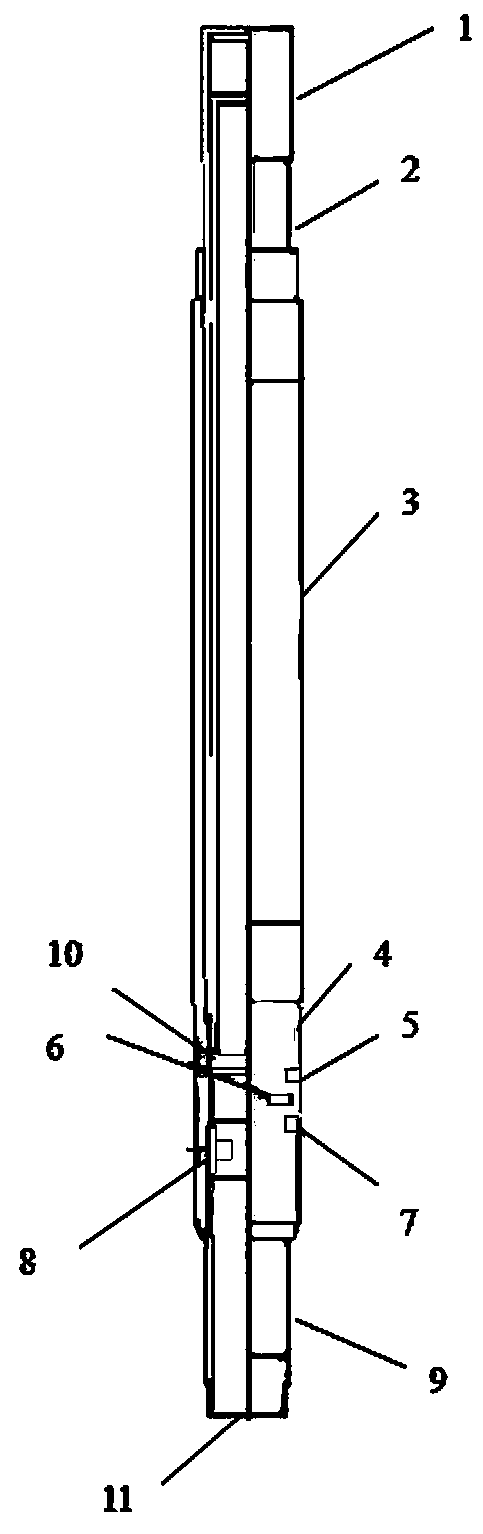

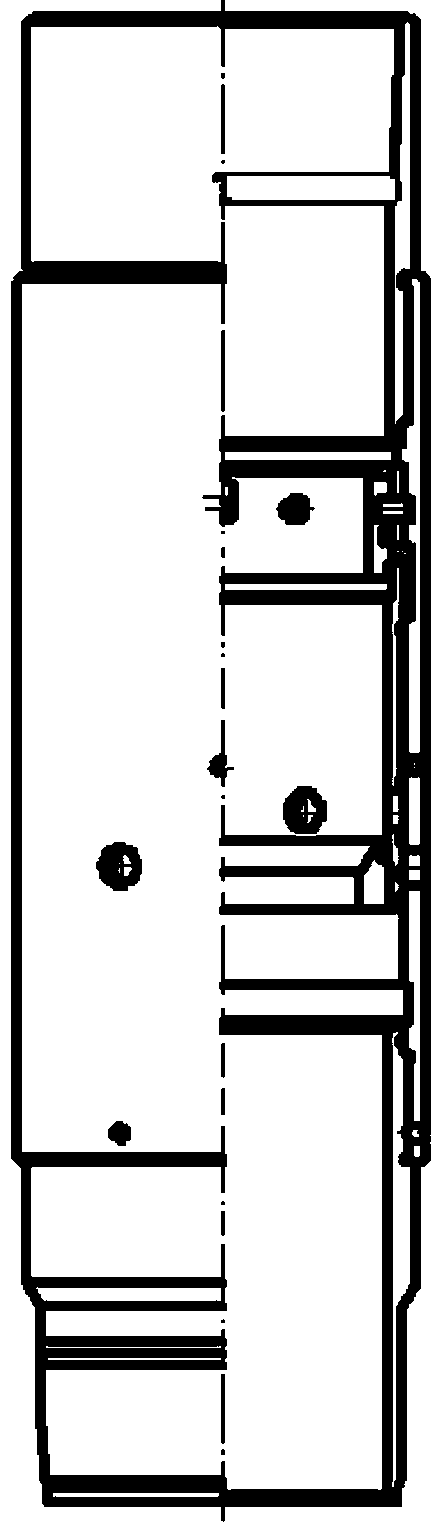

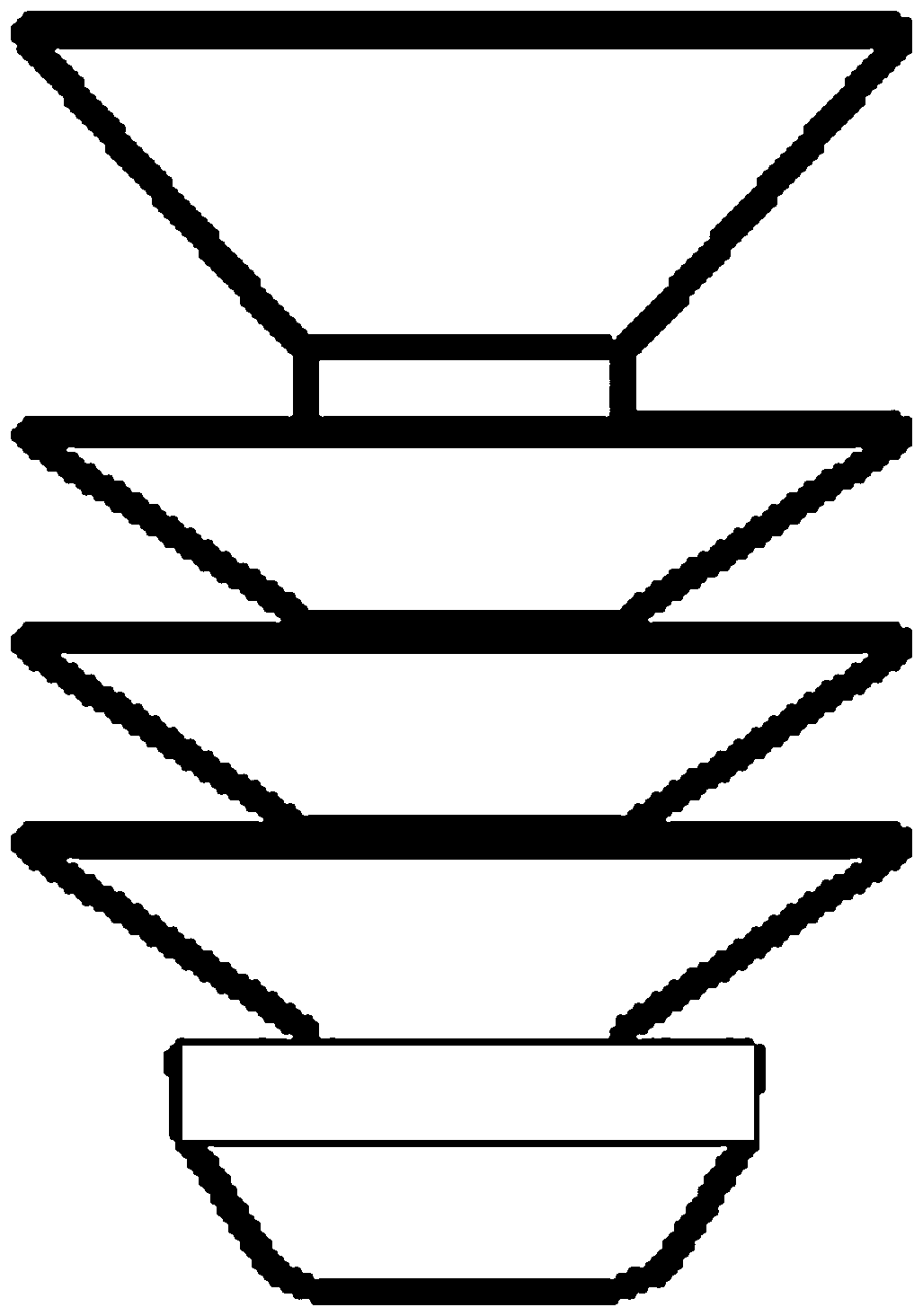

[0020] see figure 1 As shown, the formation packer includes a collar 1, a central pipe 2, a rubber sleeve 3, a valve body 4, and a pup joint 9 designed from top to bottom, and the collar 1, rubber sleeve 3, and valve body 4 are designed from top to bottom The lower sleeve is placed on the outer wall of the central pipe 2, the bottom of the valve body 4 is connected with a nipple 9, the valve body 4 includes a pressure limiting valve 5, a check valve 6, and a locking valve 7, and the valve body 4 is provided with There is disconnect lever 8. During construction, when the replacement rubber plug 10 passes through the formation packer valve body 4, the breaking rod 8 sealed on the liquid inlet hole will be broken, and when the replacement rubber plug 10 runs to the baffle plate 11, the sleeve A seal is formed in the pipe (the pipe string pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com