Air conditioning system

An air-conditioning system and evaporator technology, applied in lighting and heating equipment, irreversible cycle compressors, compressors, etc., can solve the problems that affect the stable and reliable operation of the compressor, the compressor oil continues to flow, and cannot return to the compressor, etc. , to improve performance, improve return efficiency, and improve operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

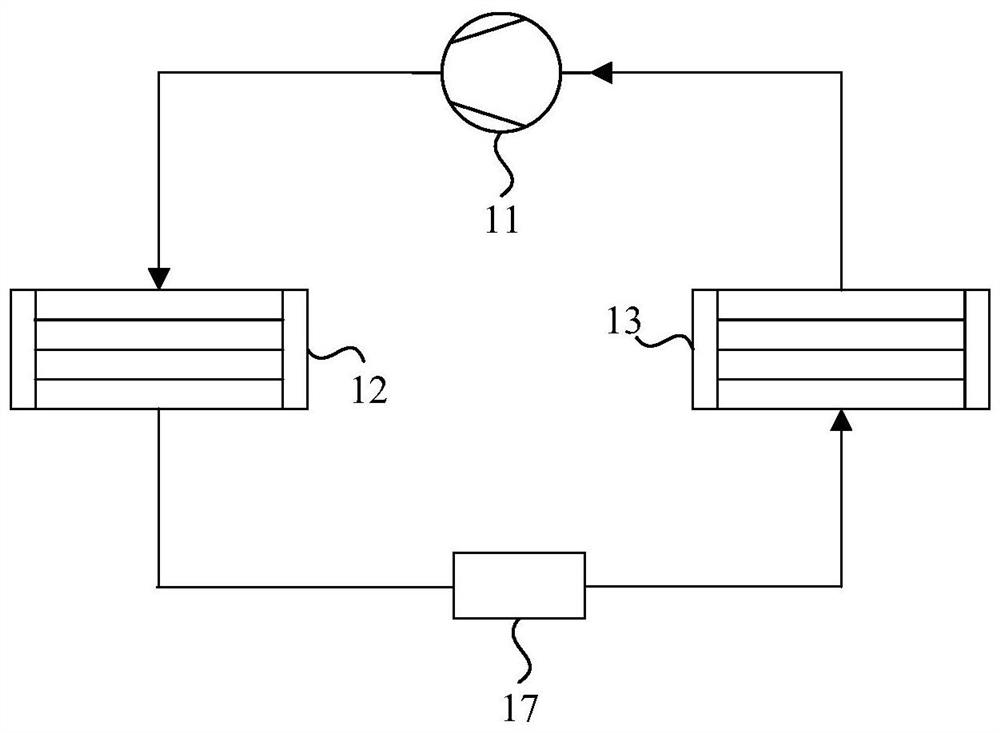

[0058] figure 1 Schematic diagram of the structure of the air conditioning system provided for the related art. refer to figure 1 As shown, the air conditioning system may include a compressor 11, a condenser 12, and an evaporator 13. The compressor 11 may compress the gaseous refrigerant into a high-temperature and high-pressure refrigerant, and the high-temperature and high-pressure refrigerant enters the condenser 12, and in the condenser 12 The liquid refrigerant enters the evaporator 13, absorbs a large amount of heat at the evaporator 13, and then turns into a gaseous state, and then enters the compressor 11 for recirculation.

[0059] A throttling device 17 is also connected between the condenser 12 and the evaporator 13. The specific structure of the throttling device 17 includes but is not limited to an electronic expansion valve, a thermal expansion valve, a capillary tube, etc. The throttling device 17 is used for high-pressure liquid refrigeration. The refrigeran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com