Pull-rod schoolbag

A technology of school bags and trolleys, which is applied in the field of student supplies, can solve the problems of poor flexibility and inconvenient use, and achieve the effects of good cushioning and shock absorption, convenient use and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

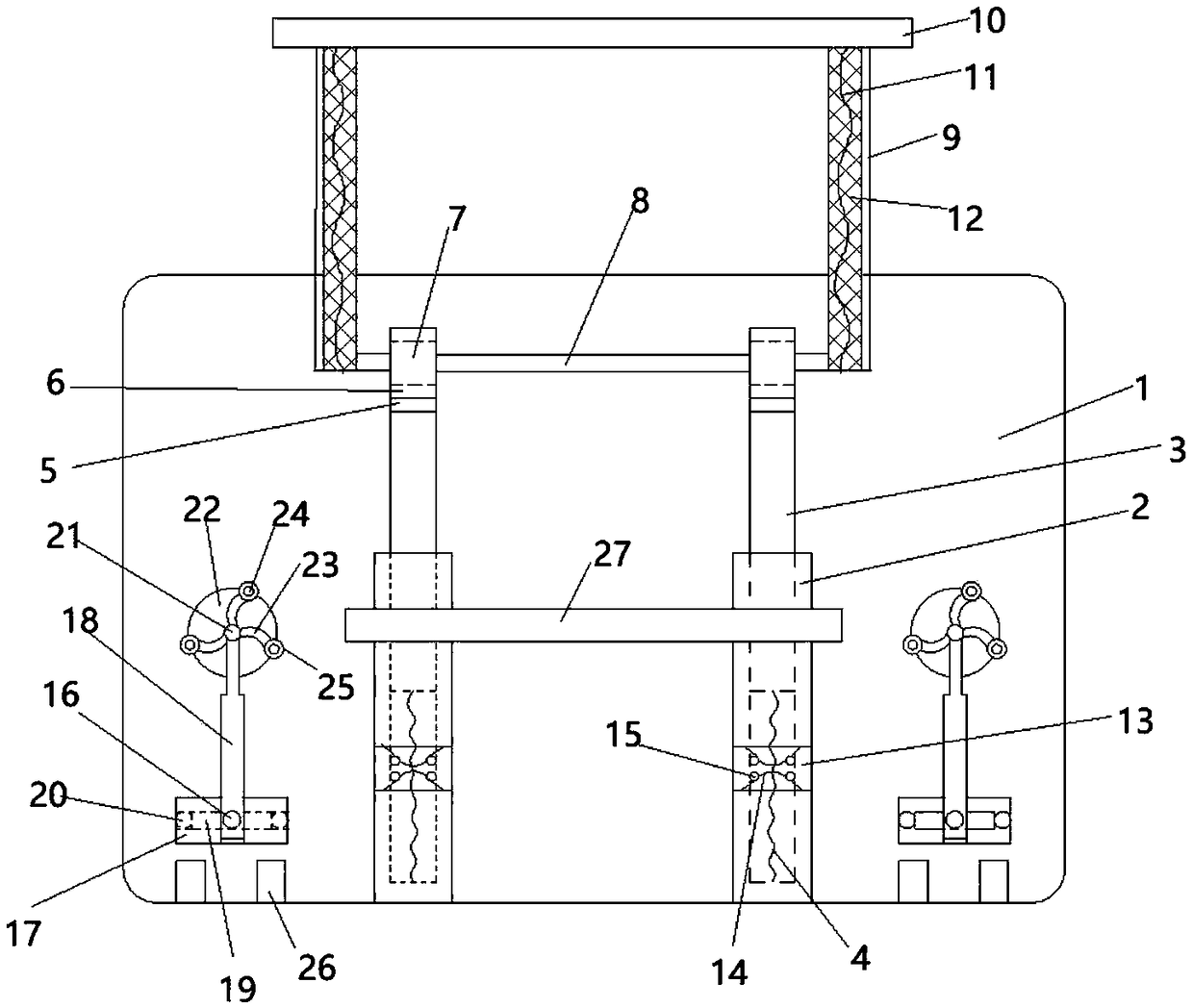

[0021] A trolley schoolbag, see figure 1 , the trolley schoolbag includes a bag body 1, two outer tubes 2 are evenly distributed on the back of the bag body 1, and inner rods 3 are respectively arranged in the outer tubes 2, and the lower end surface of the inner rod 3 is connected to the bottom surface of the outer tube 2. The lower springs 4 are respectively connected between them, the upper ends of the inner rods 3 are respectively connected with the outer ring gear 6 through the hinge 5, the inner gear shafts 7 are respectively meshed in the outer ring gears 6, and the upper end of the inner gear shafts 7 is jointly connected with an upper spring. The two ends of the rotating shaft 8 and the upper rotating shaft 8 are respectively located outside the inner gear shaft 7, and the two ends of the upper rotating shaft 8 are respectively connected with the lower end of the elastic arc plate 9, and the upper ends of the elastic arc plate 9 are connected with the upper cross bar 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com