High-temperature oil resistant molded component for automobile

A molding part, high temperature technology, applied in the field of molding parts, can solve the problems of poor oil resistance of PBT resin, deterioration of dimensional stability and strength of molded parts, generation of voids, etc., and achieve the effect of excellent high temperature oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 9 and comparative example 1 to 4

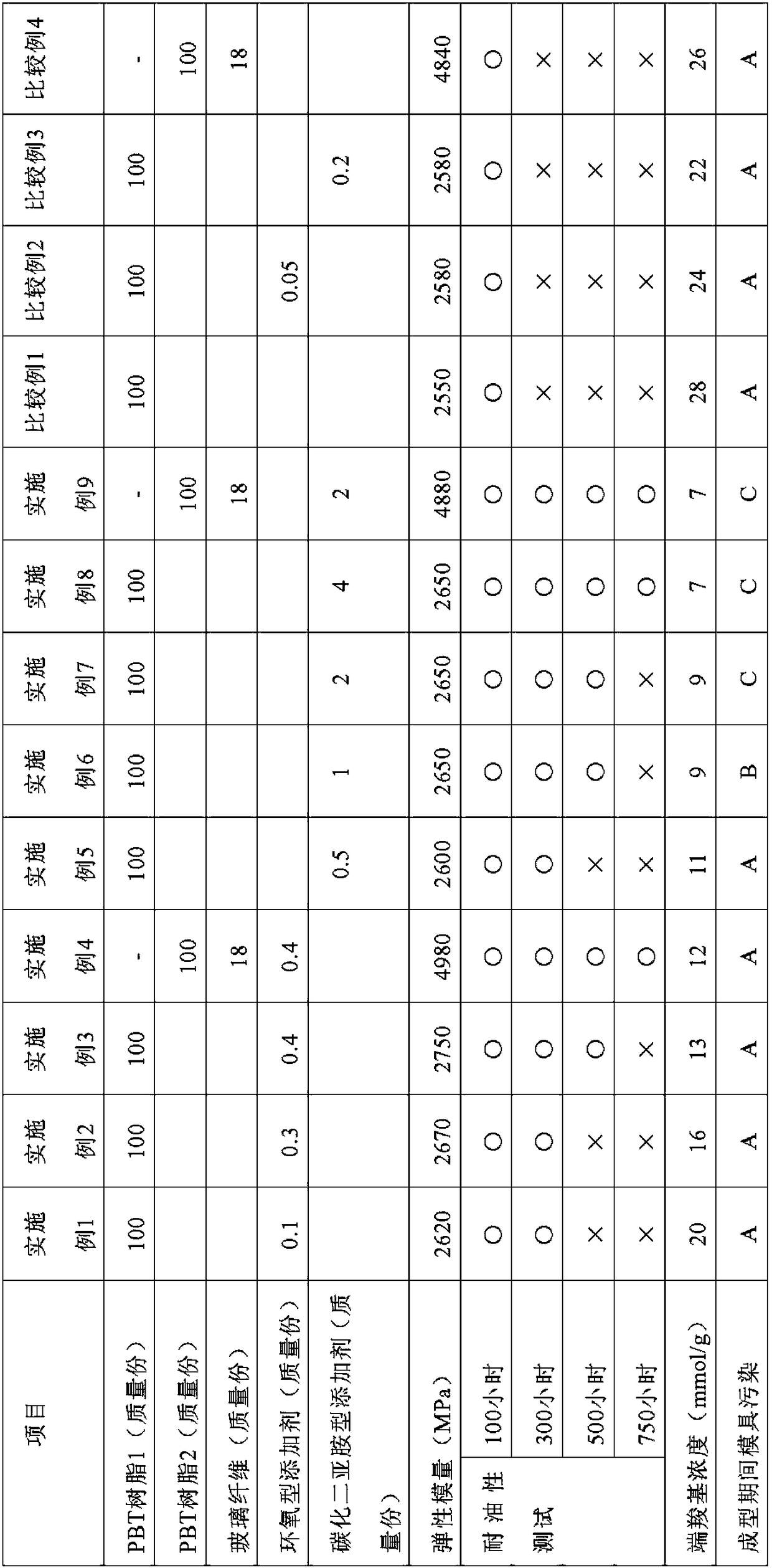

[0057] In each example or comparative example, a resin composition containing the components listed in Table 1 below was produced. Using this resin composition, injection molding was performed by a horizontal molding machine manufactured by FUNAC Co., Ltd. at a resin temperature of 260° C. and a mold temperature of 80° C. to obtain a test piece 127 mm long, 12.7 mm wide, and 1.6 mm thick piece. Using the obtained test pieces, the following evaluation tests were performed.

[0058] [Table 1]

[0059]

[0060] Details of the individual components in Table 1 are described below.

[0061] PBT resin 1: PBT non-reinforced material manufactured by Toray Industries, Inc. 1401-X06

[0062] PBT resin 2: PBT SK602 manufactured by Du Pont

[0063] * As a PBT-G15 material, 18 parts by mass of glass fibers are contained per 100 parts by mass of PBT resin.

[0064] Epoxy type additive (epoxy compound): JONCRYL ADR4368 manufactured by BASF

[0065] Carbodiimide-type additive (carbodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com