Assembled staggered floor cross arm tangent tower and tower erection method thereof

A prefabricated, linear tower technology, applied in the field of transmission linear towers, can solve the problems of difficult electrical performance, mechanical performance and economic performance of conductors, ground wires and transmission towers, large design workload, and difficult assembly. The effect of reducing the difficulty of assembly, improving construction efficiency and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

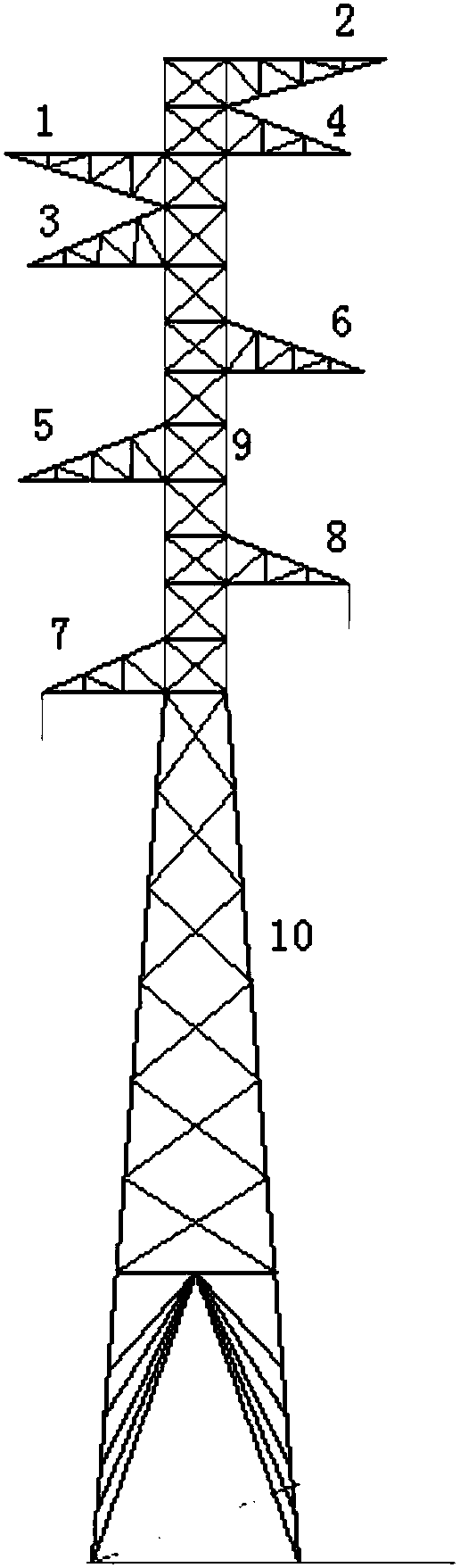

[0034] Such as figure 1 As shown, the present invention provides an assembled staggered cross-arm straight tower, including a tower body and a cross-arm vertically arranged with the tower body; the tower body includes an upper tower body 9 and a lower tower body 10; The upper tower body 9 is in a vertical direction; the cross arms are staggeredly distributed on both sides of the upper tower body 9 .

[0035] The cross-arms on both sides of the tower body respectively include ground wire cross-arms and wire cross-arms distributed from top to bottom; The cross arm 7; the wire cross arm on the right side includes the upper right wire cross arm 4, the right middle wire cross arm 6, and the right lower wire cross arm 8; the left ground wire cross arm 1 is arranged on the upper side of the left upper wire cross arm 3; The right ground wire cross arm 2 is arranged on the upper side of the upper right wire cross arm 4 .

[0036] The vertical height of the ground wire cross arm is eq...

Embodiment 2

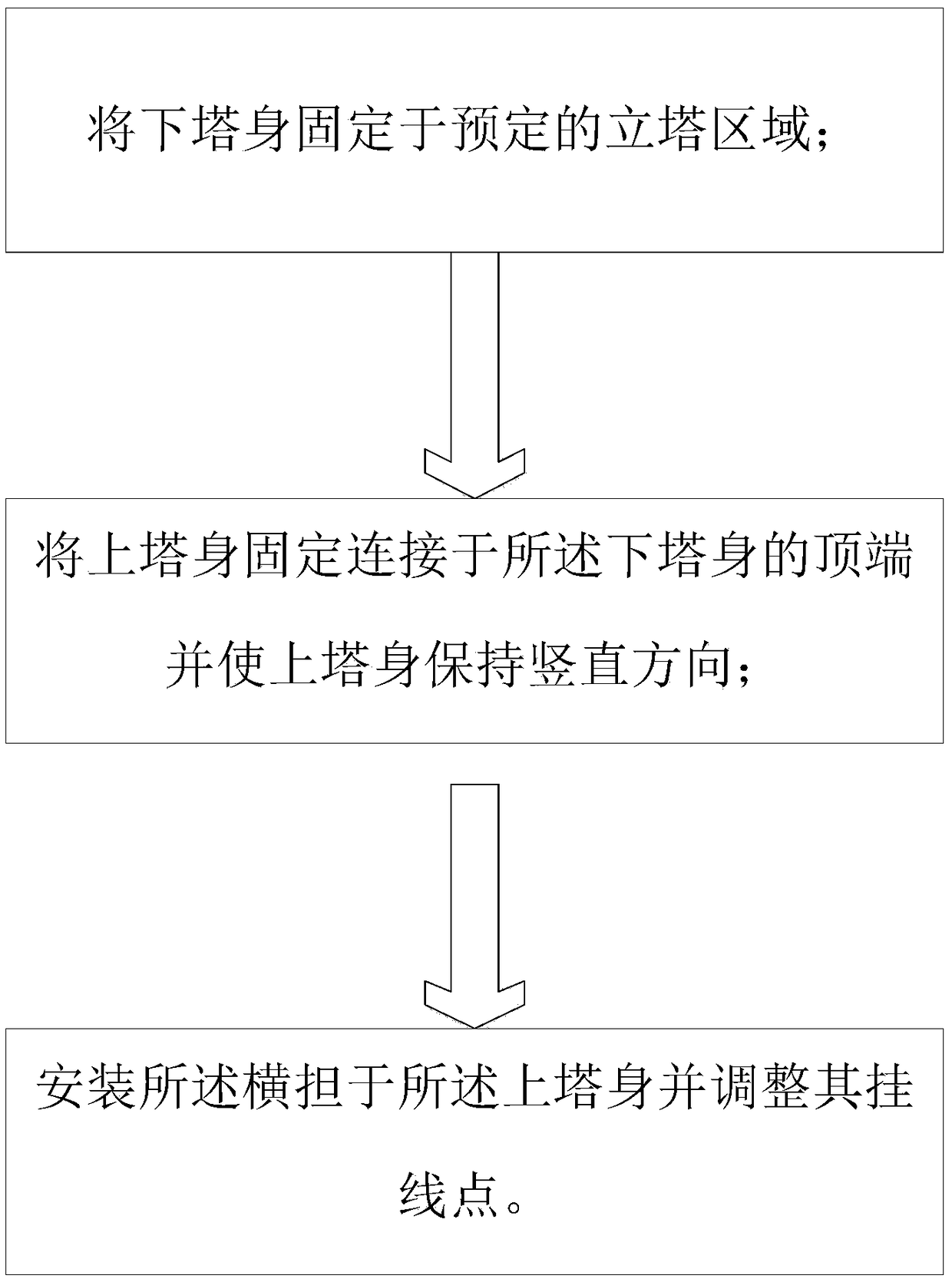

[0048] Such as figure 2 As shown, based on the unified inventive concept, the present invention also provides a method for erecting the above-mentioned prefabricated split-level cross-arm straight tower, the method comprising the following steps:

[0049] (1) The lower tower body 10 is fixed to a predetermined vertical tower area;

[0050] (2) The upper tower body 9 is fixedly connected to the top of the lower tower body 10 and the upper tower body 9 is kept vertical;

[0051] (3) Install the cross arm on the upper tower body 9 and adjust its hanging point.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com