Order picking method based on electronic label and system thereof

An electronic label and truck technology, applied in the picking system, in the field of picking based on electronic labels, can solve the problems of low sorting efficiency and accuracy, low commodity aggregation, and a large number of manual sorting, and achieve high efficiency in the picking process. , the effect of low error rate and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

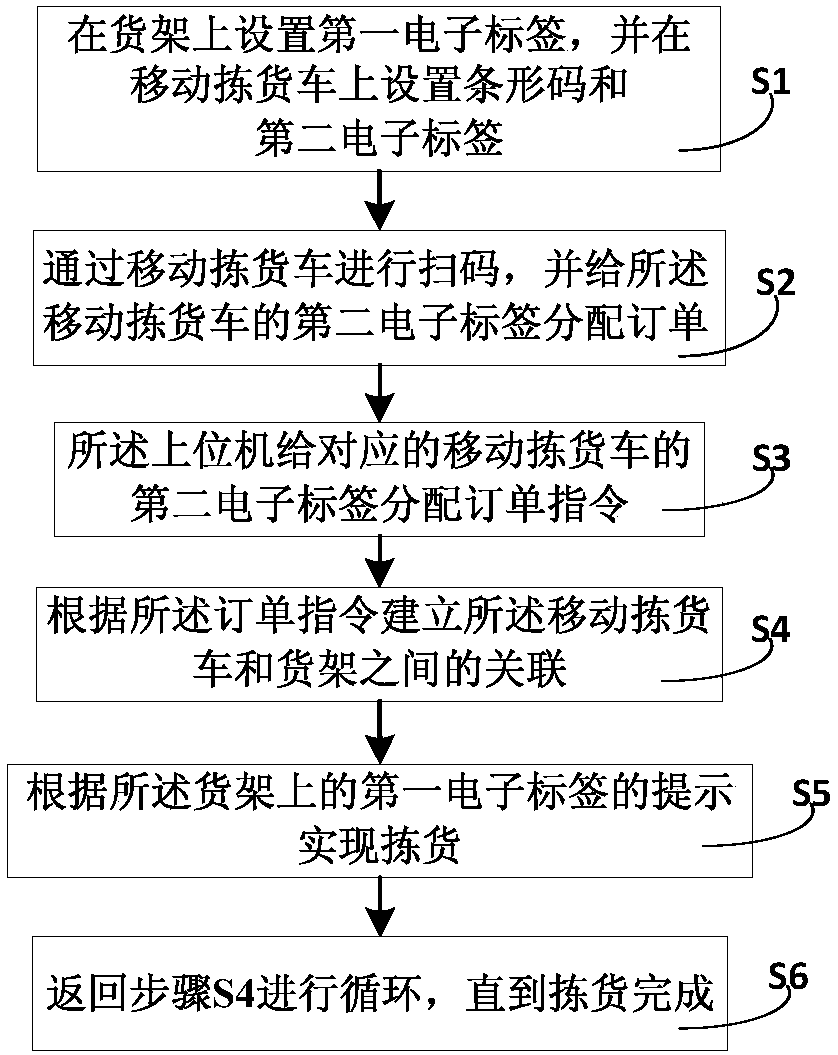

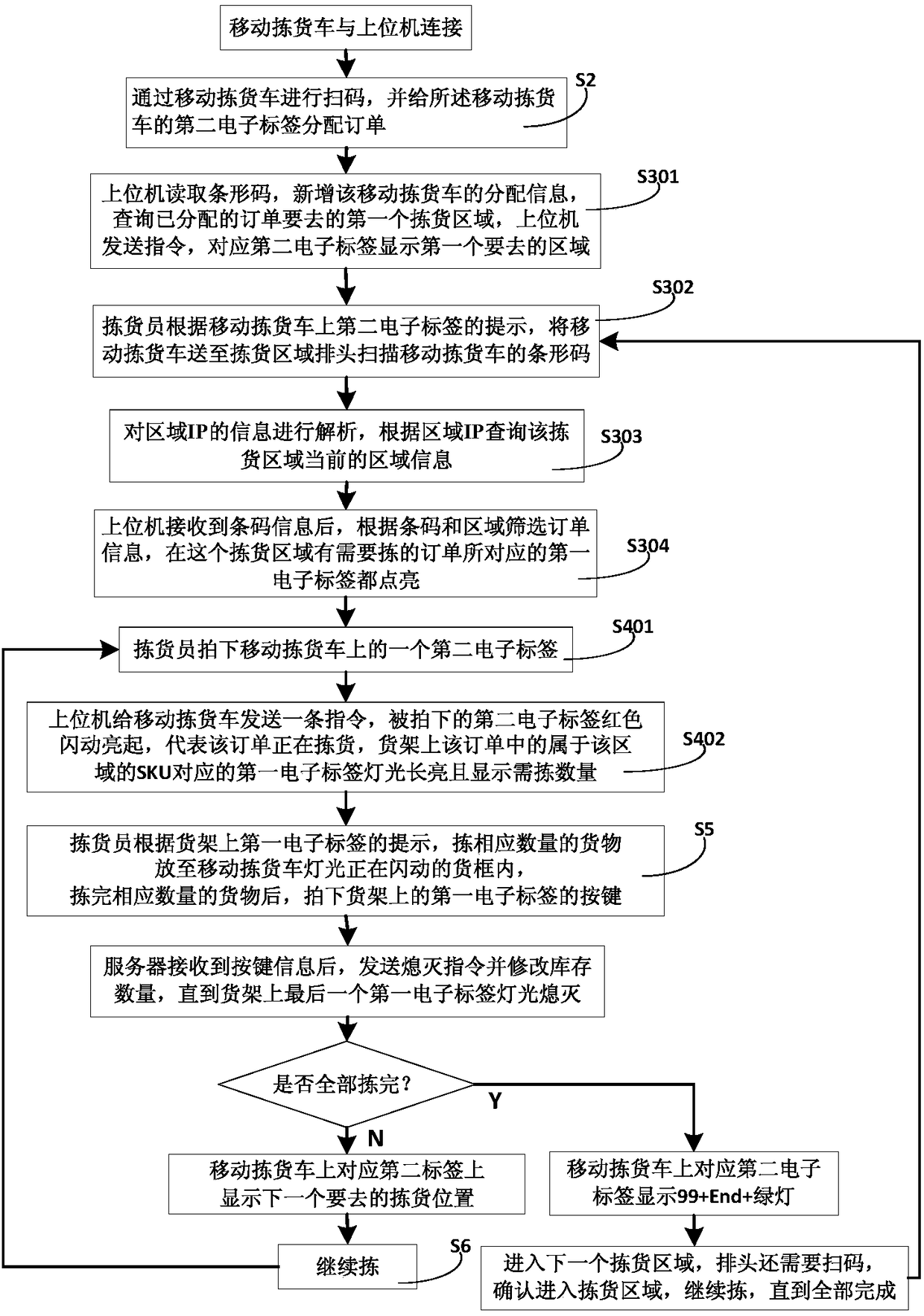

[0035] Such as figure 1 with figure 2 As shown, this example provides a picking method based on electronic tags, including the following steps:

[0036] Step S1, setting the first electronic label on the shelf, and setting the barcode and the second electronic label on the mobile picking cart;

[0037] Step S2, scan the code through the mobile picking vehicle, then receive and analyze the barcode message obtained by scanning the code through the host computer, and assign an order to the second electronic label of the mobile picking vehicle according to the barcode message;

[0038] Step S3, the host computer assigns an order instruction to the second electronic tag of the corresponding mobile picking vehicle, and the order instruction includes picking area information and a signal to be picked;

[0039] Step S4, establishing the association between the mobile picking vehicle and the shelf according to the order instruction;

[0040] Step S5, realizing picking according to ...

Embodiment 2

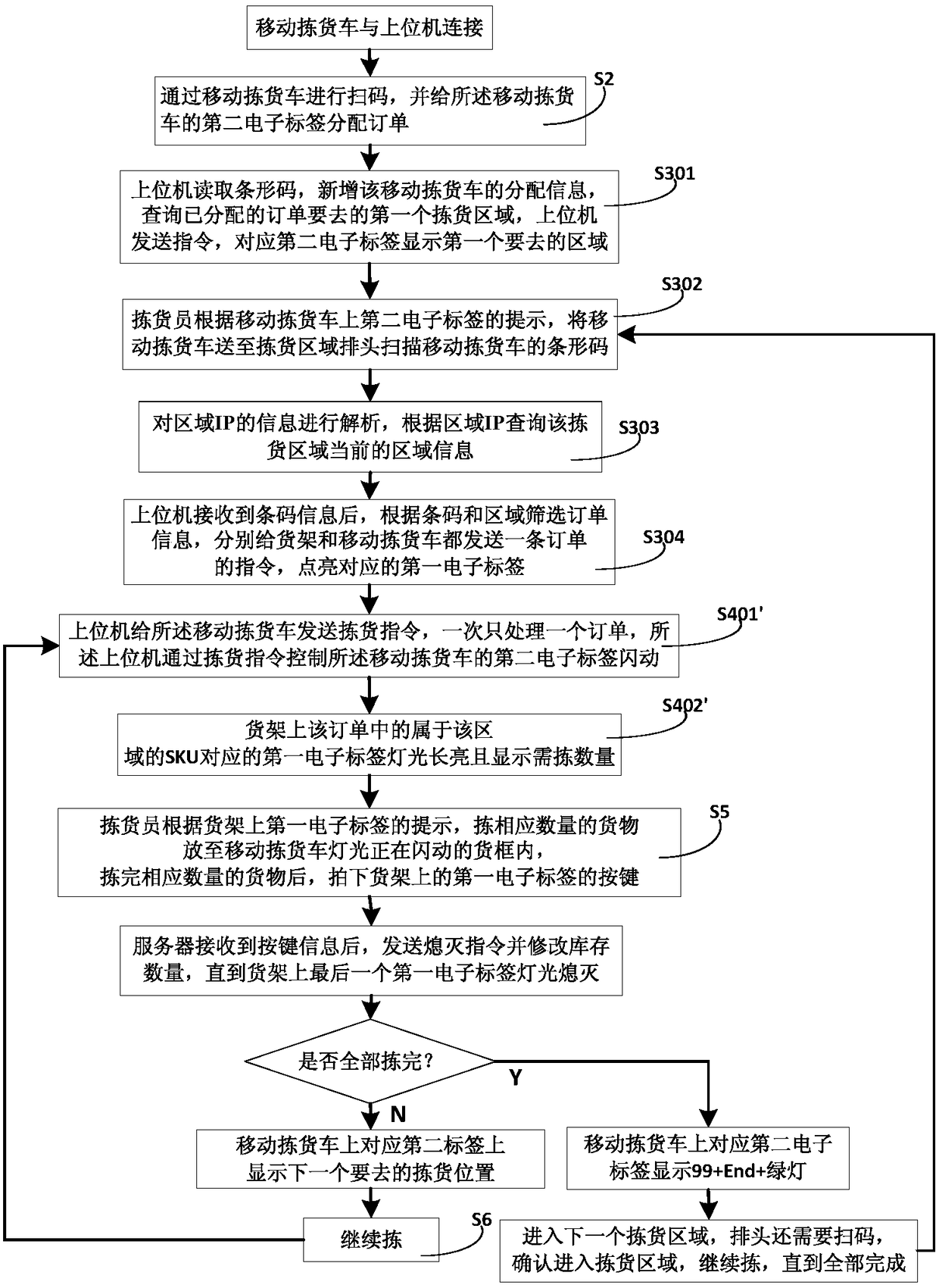

[0064] Such as figure 1 with image 3 As shown, the difference between this example and Embodiment 1 is that the step S4 includes the following sub-steps:

[0065] Step S401', the upper computer sends a picking instruction to the mobile picking vehicle, and only one order is processed at a time, and the upper computer controls the second electronic label of the mobile picking vehicle to flash through the picking instruction;

[0066] Step S402', the host computer controls the first electronic label corresponding to the flashing second electronic label to light up through the picking instruction, and displays the quantity.

[0067] In step S4 described in this example, according to the barcode information and area of the second electronic label, the assigned and unfinished orders of the mobile picking vehicle are queried, and then the host computer finds the connection channel of the mobile picking vehicle and sends a picking instruction , and only one order is processed at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com