Rapid radish slicing and slitting device

A fast and slicing technology, applied in metal processing and other directions, can solve the problems of slow speed and hard work, and achieve the effect of fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

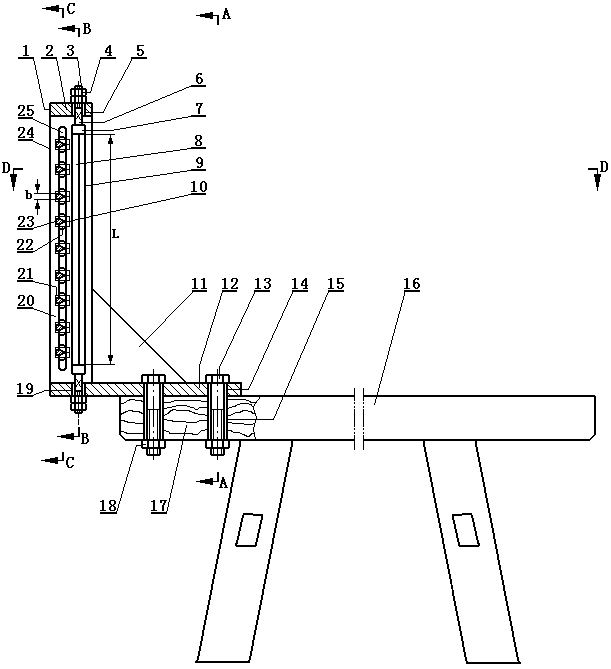

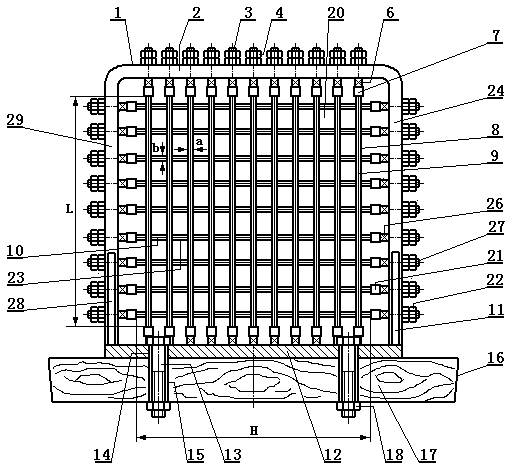

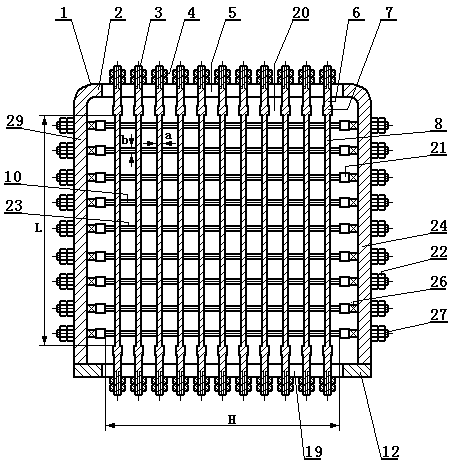

[0042] Embodiment: as shown in accompanying drawing, by knife rest 1, first nut 4, vertical cutter 8, rear reinforcement board 11, knife rest bottom plate 12, bolt 13, wooden bench 16, second nut 18, the third A kind of fast slicing and bar cutter of radish that nut 22, transverse cutter 23 and front reinforcing plate 28 constitute, the right end of the square inner space 20 that knife rest 1 and knife rest bottom plate 12 constitute are provided with 11 evenly distributed and mutually parallel The vertical cutter 8 that can regulate the thickness of cutting radish slices and radish strips, the right end of every vertical cutter 8 is provided with sharp vertical blade 9, the square inner space 20 that knife rest 1 and knife rest bottom plate 12 constitute The left end of the radish is provided with 9 horizontal cutters 23 that are evenly distributed and parallel to each other and can adjust the width of the radish strips. The right end of each horizontal cutter 23 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com