Novel manual stock cutter

A material cutting machine and manual technology, applied in metal processing and other directions, can solve the problems of large manpower and material resources consumption, poor processing quality, high labor intensity, etc., and achieve the effect of easy speed, speed control, stable and reliable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

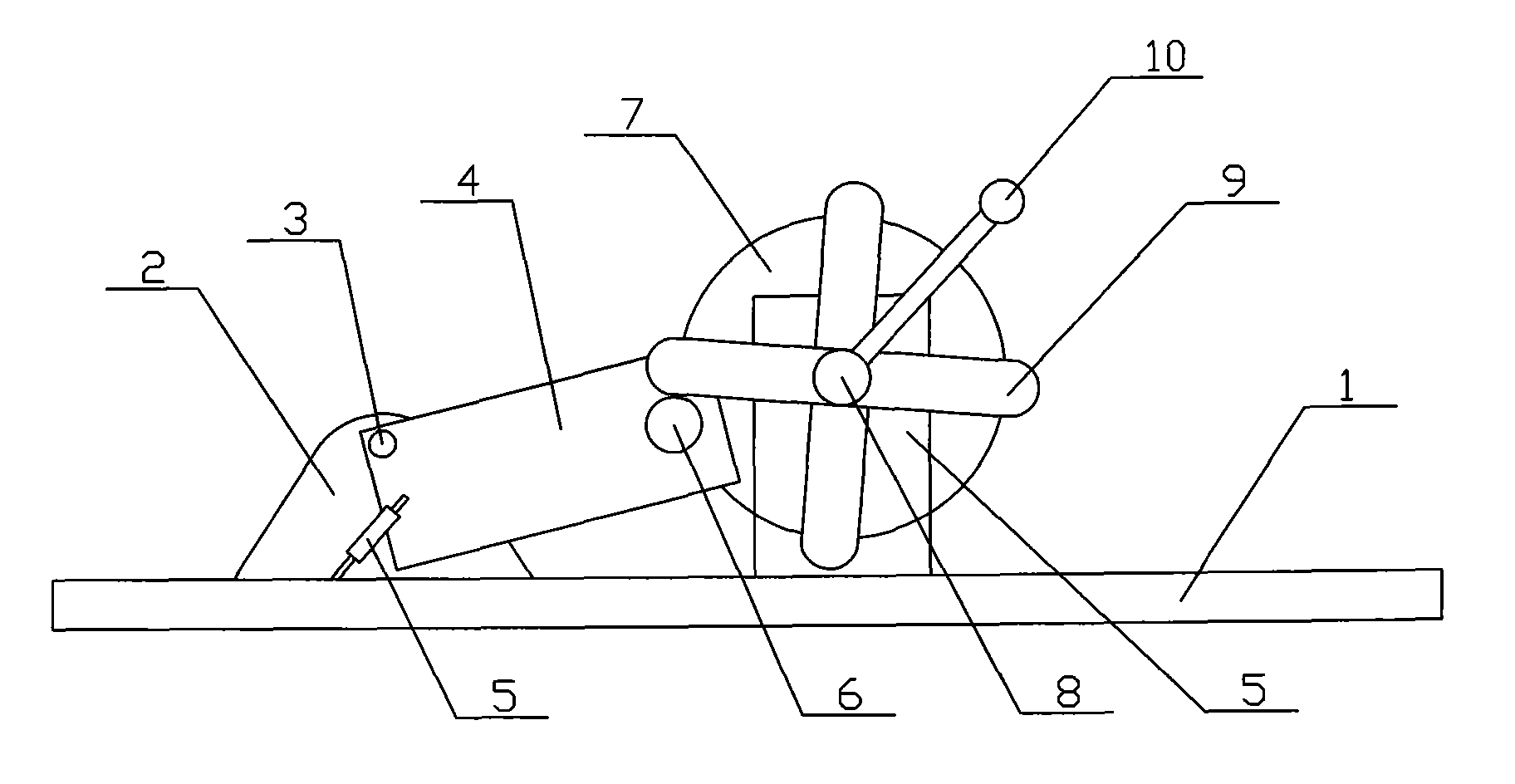

[0007] see figure 1 , the specific embodiment adopts the following technical scheme: it comprises a base 1, a support seat 2, a shaft 3, a blade 4, an air spring 5, a bump 6, a turntable 7, a rotating shaft 8, a lever 9 and a rocker 10, and supports Seat 2 is arranged on the upper end of base 1, and its upper end is movably connected with blade 4 through shaft 3, and the surface of blade 4 is provided with bump 6, and one end of air spring 5 is connected with base 1, and the other end is connected with shaft 3, and the turntable 7 Two intersecting driving rods 9 are arranged on the surface, the rotating shaft 8 passes through the support base 2 and is fixedly connected with the driving rod 9 , and one end of the rocking handle 10 is connected with the driving rod 9 .

[0008] When the rocking handle 10 is rotated, the driving lever 9 will also rotate, thereby pressing down the projection 6, and when the driving lever 9 leaves the projection 6, it will reset quickly by the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com