Preparation method and application of aluminum-based light high-entropy alloy metal powder cored welding wire

A metal powder core and high-entropy alloy technology, applied in metal processing equipment, welding equipment, welding media, etc., can solve the problems of expensive powder, high price, and inability to prepare large components, and achieve good hardness, uniform chemical composition and structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

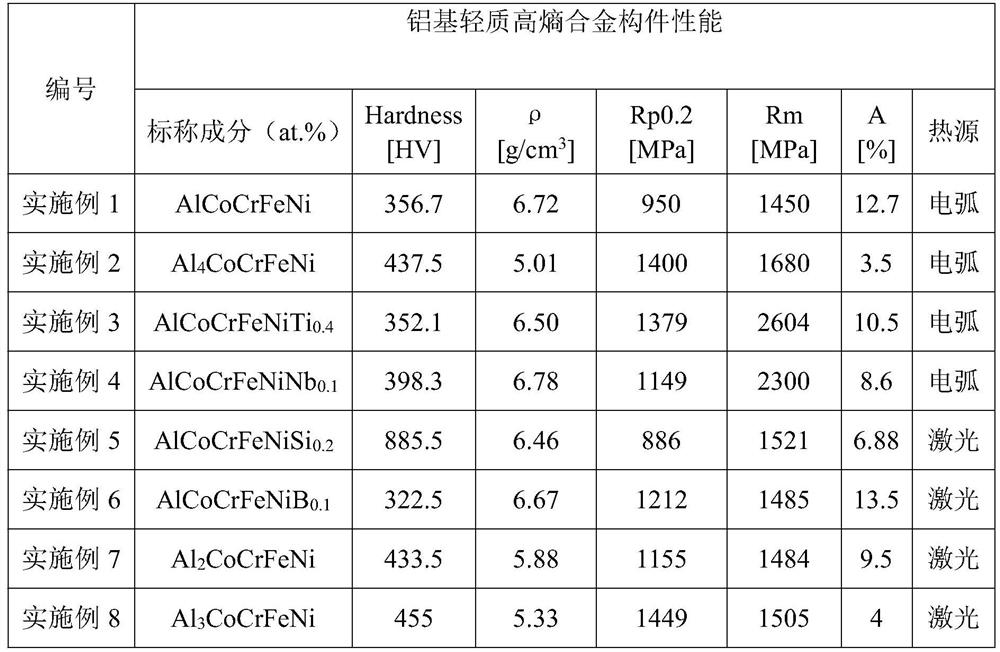

Embodiment 1

[0027] An aluminum-based lightweight high-entropy alloy metal powder-cored welding wire, the chemical composition of which includes: Al: 10.688%, Co: 23.345%, Cr: 20.597%, Fe: 22.121%, Ni: 23.250%.

[0028] Further, its preparation method specifically includes the following steps:

[0029] S1, first weigh 40.833 grams of Co powder, 36.027 grams of Cr powder, 38.694 grams of Fe powder, and 40.667 grams of Ni powder. The above-mentioned powders are all high-purity (purity ≥ 99.99%) metal powders, followed by weighing 4.687 grams of ethanol process control agent;

[0030]S2. Put the weighed high-purity metal powder and process control agent into the ball mill tank, and at the same time put stainless steel balls into the ball-to-material ratio of 10:1, and fully ball mill for 20 hours until the metal powder is alloyed;

[0031] S3, cold rolling the pure aluminum strip to 0.1mm, then cutting it into 7mm wide, and rolling it into a U-shaped groove, filling the above-mentioned alloy ...

Embodiment 2

[0034] An Al-based lightweight high-entropy alloy metal powder-cored welding wire, the chemical composition of which includes: Al: 32.372%, Co: 17.677%, Cr: 15.596%, Fe: 16.751%, Ni: 17.605%.

[0035] Further, its preparation method specifically includes the following steps:

[0036] S1, first weigh 60.760 grams of Co powder, 53.608 grams of Cr powder, 57.576 grams of Fe powder, 6.512 grams of Ni powder, and the above powders are all high-purity (purity ≥ 99.99%) metal powders; secondly, weigh 6.97 grams of ethanol as a process control agent ;

[0037] S2. Put the weighed high-purity metal powder and process control agent into the ball mill tank, and at the same time put stainless steel balls in the ball-to-material ratio of 20:1, and fully ball mill for 15 hours until the metal powder is alloyed;

[0038] S3, cold rolling the pure aluminum strip to 0.46mm, then cutting it into 9mm wide, and rolling it into a U-shaped groove, filling the above-mentioned alloy powder, and clos...

Embodiment 3

[0041] An Al-based lightweight high-entropy alloy metal powder-cored welding wire, its chemical composition includes: Al: 9.934%, Co: 21.699%, Cr: 19.145%, Fe: 20.562%, Ni: 21.611%, Ti: 7.050 %.

[0042] Further, its preparation method specifically includes the following steps:

[0043] S1, first weigh 58.806 grams of Co powder, 51.884 grams of Cr powder, 55.724 grams of Fe powder, 58.566 grams of Ni powder, 19.105 grams of Ti powder, the above powders are all high-purity (purity ≥ 99.99%) metal powder; secondly weigh 7.322 grams Ethanol process control agent;

[0044] S2. Put the weighed high-purity metal powder and process control agent into the ball mill tank, and at the same time put stainless steel balls into the ball-to-material ratio of 40:1, and fully ball mill for 10 hours until the metal powder is alloyed;

[0045] S3, cold rolling the pure aluminum strip to 0.11mm, then cutting it into 9mm wide, and rolling it into a U-shaped groove, filling it with the above-ment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com