Parallel R-type automobile shock absorber for recovering energy by turbines and method

A technology for energy recovery and shock absorbers, applied in the direction of shock absorbers, spring/shock absorber functional characteristics, spring/shock absorber design features, etc., can solve the problem that vibration energy consumption cannot be recovered, and achieve simple and easy technical means operation, lower operating temperature, cleverly conceived effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

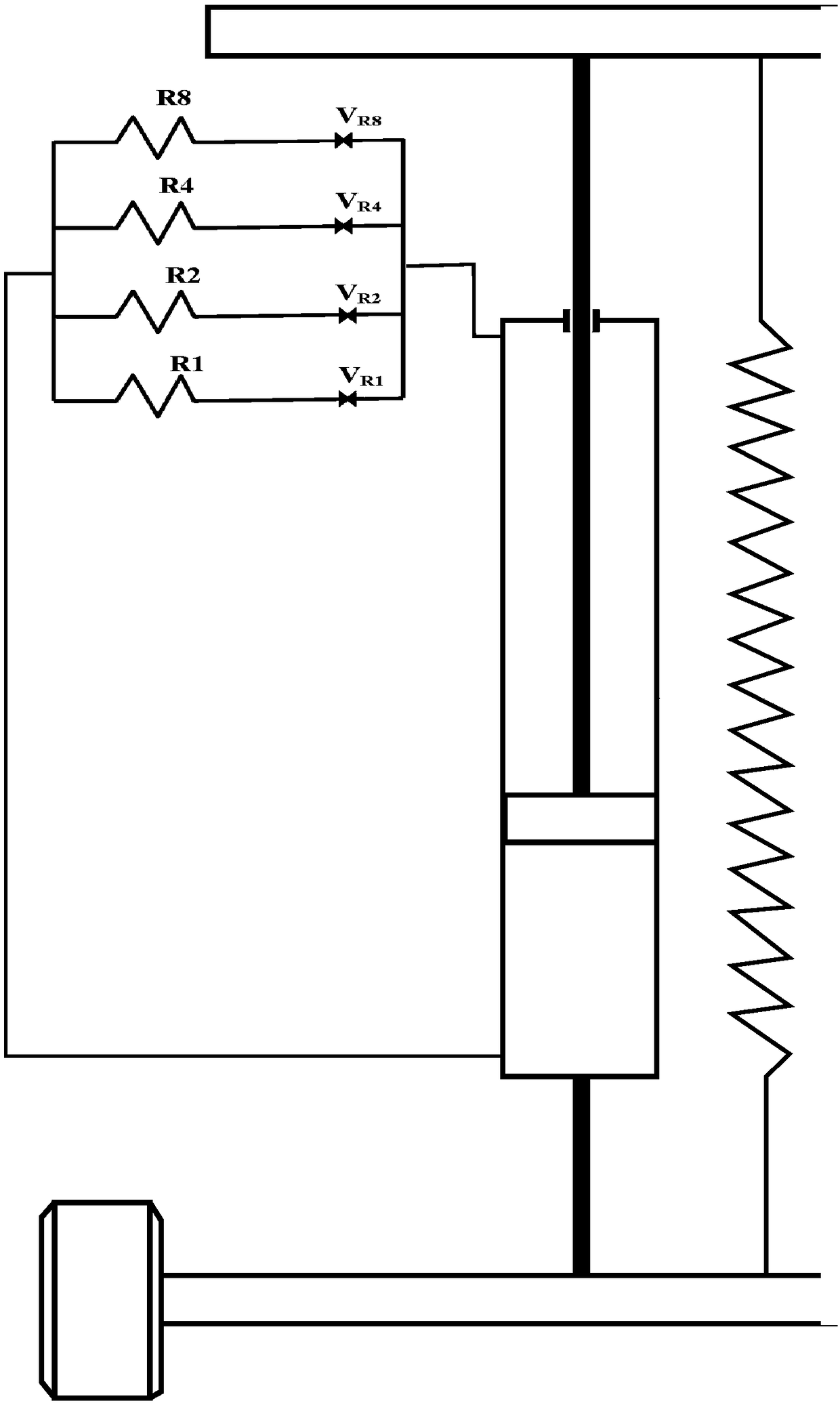

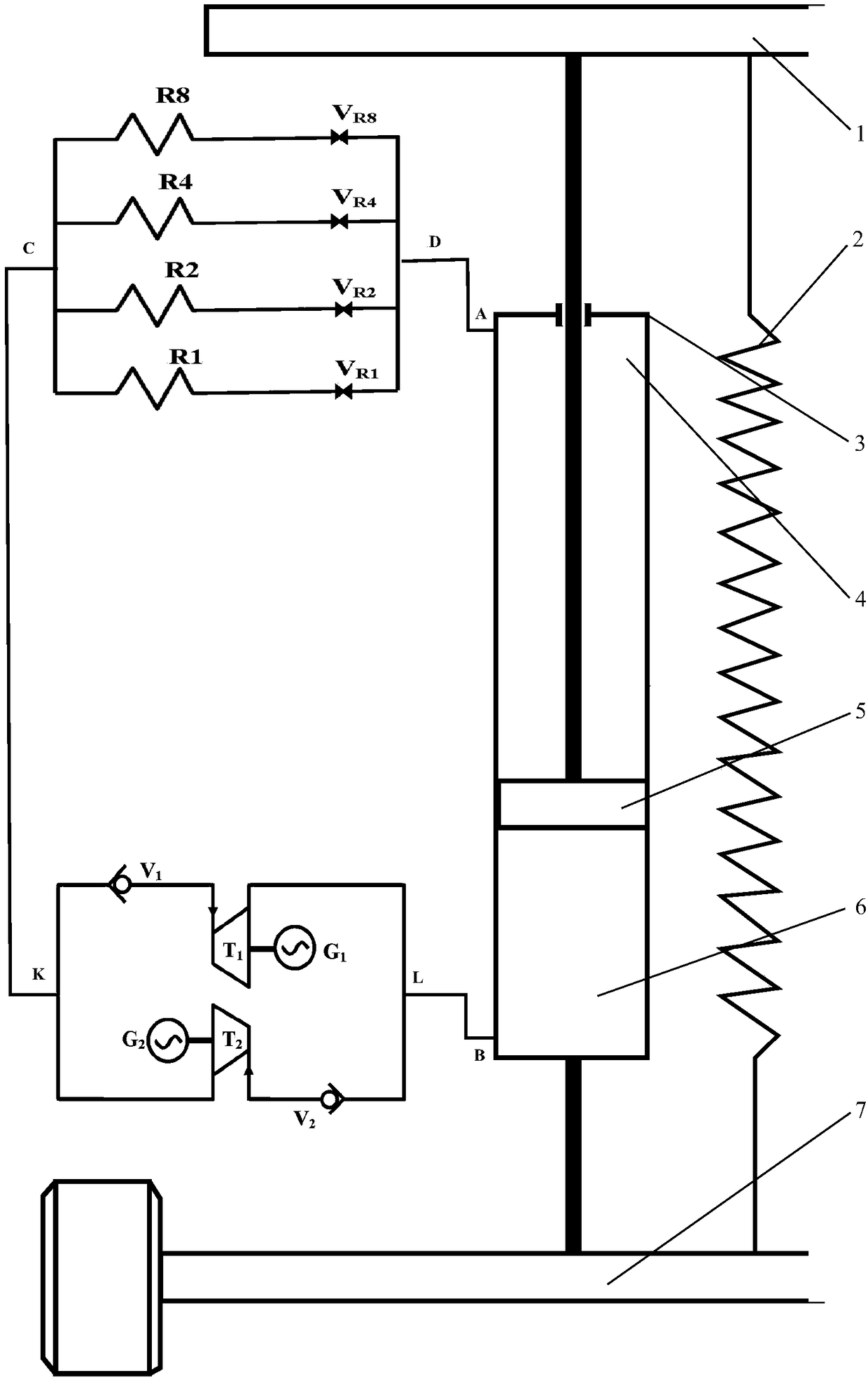

[0034] as attached figure 2 shown.

[0035] The resistance adjustment section includes four capillary tubes respectively R8, R4, R2 and R1; they are equal in length and connected in series with the solenoid valve V R8 , V R4 , V R2 , V R1 control its work. The ratio of the cross-sectional areas of the four capillaries is 8:4:2:1.

[0036] Twin-turbo energy recovery section including non-return valve V 1 , one-way valve V 2 , Turbo T 1 , Turbo T 2 , Generator G 1 , Generator G 2 . In this embodiment, the turbine T 1 , Turbo T 2 Choose the same parameters, that is, their flow ranges are the same. Select the maximum flow Q of the turbine Tmax The maximum hydraulic oil flow rate Q than the shock absorber Smax 10% larger; ie: Q Tmax =1.1Q Smax .

[0037] When there is relative movement between the frame and the axle, the piston will move up or down accordingly; the upward movement of the piston is the extension stroke, and the downward movement of the piston is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com