Turbine energy recovery parallel connection and series connection R type automobile shock absorber and method

A technology for recovering energy and shock absorbers, applied in the direction of shock absorbers, spring/shock absorber functional characteristics, spring/shock absorber design features, etc. OK, lower operating temperatures, cleverly conceived effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

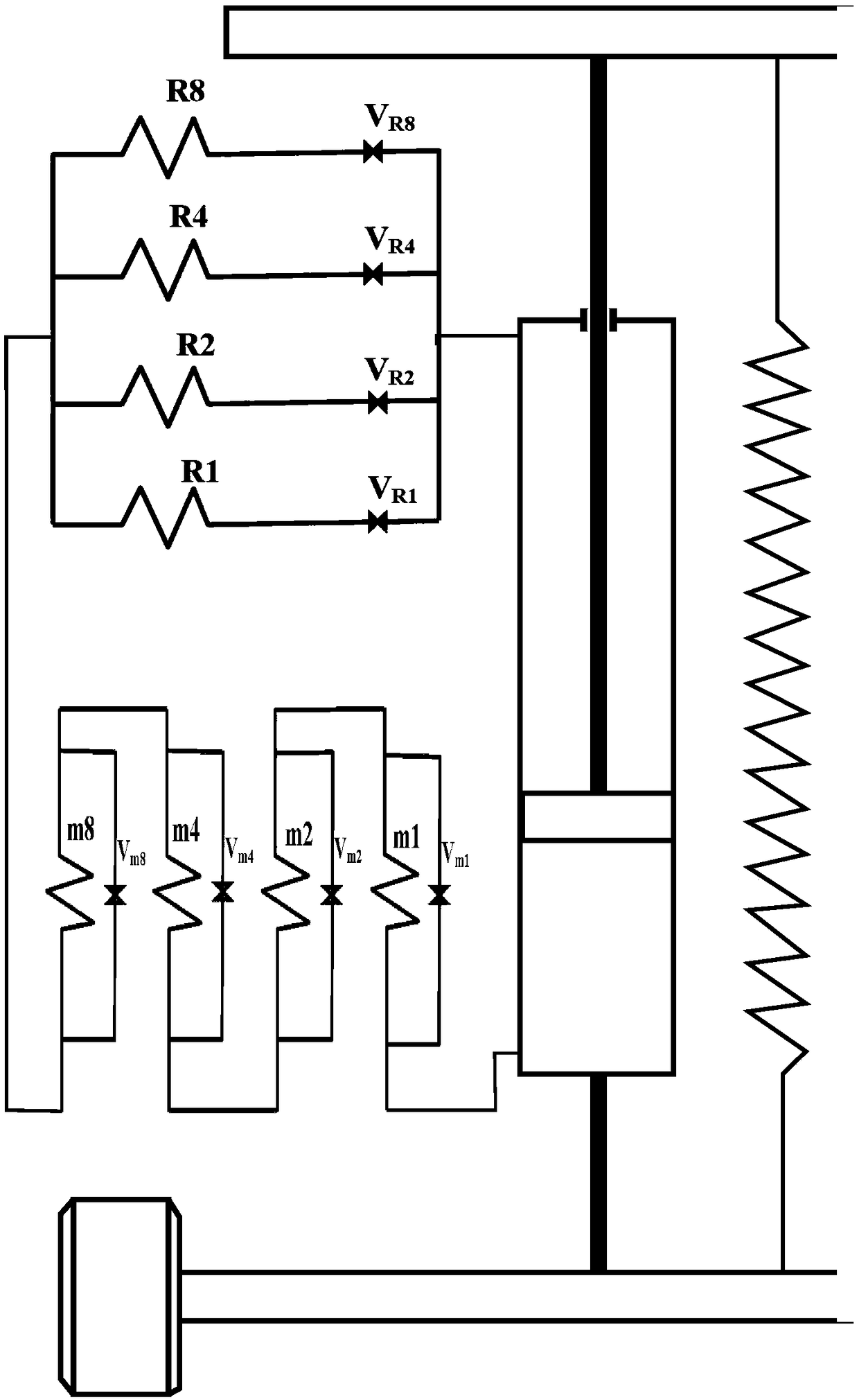

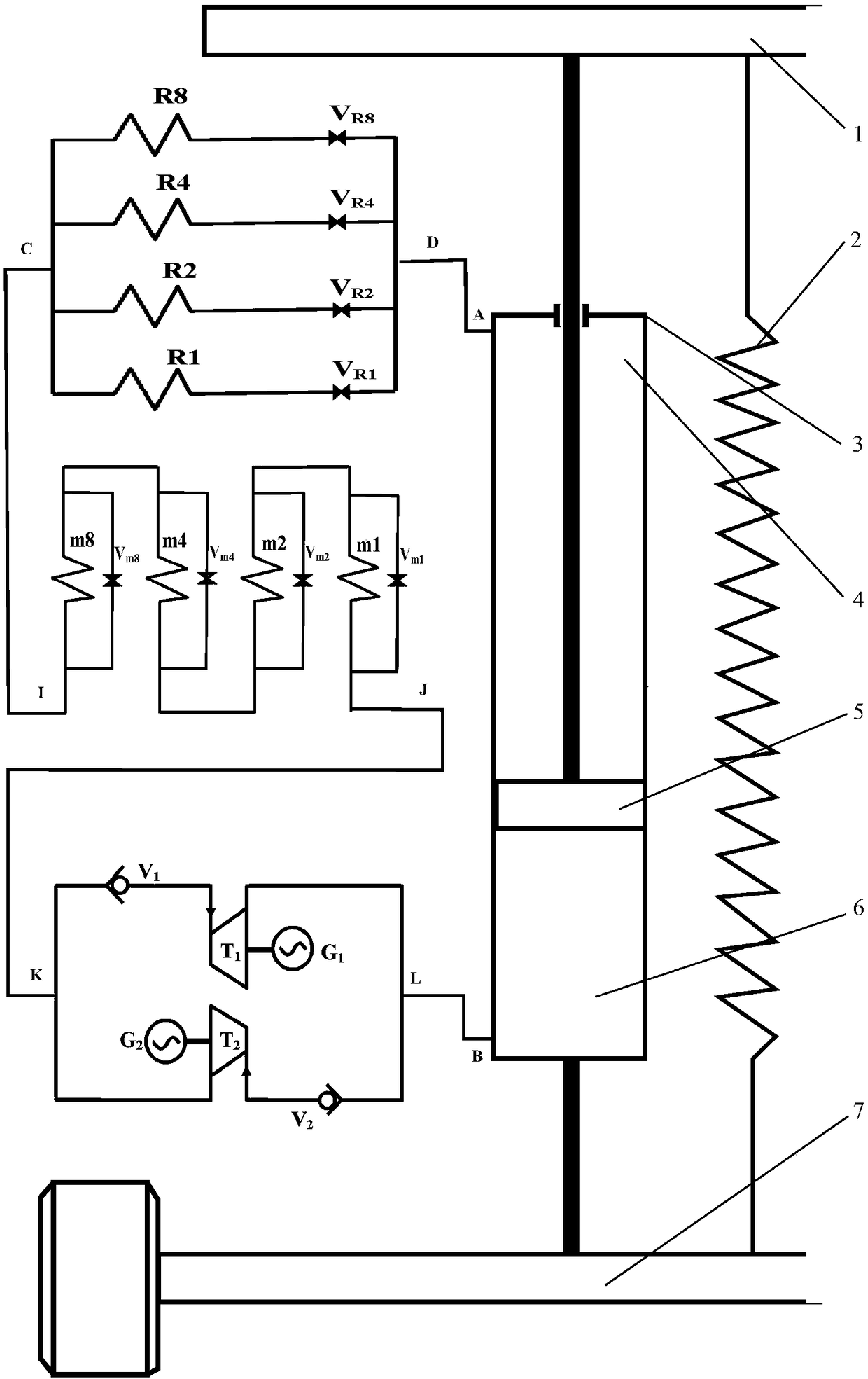

[0037] as attached figure 2 shown.

[0038] The resistance adjustment section includes four capillary tubes respectively R8, R4, R2 and R1; they are equal in length and connected in series with the solenoid valve V R8 , V R4 , V R2 , V R1 control its work. The ratio of the cross-sectional areas of these four capillaries is 8:4:2:1; their lengths are all L R .

[0039] The frequency modulation section includes four capillary tubes which are m8, m4, m2 and m1; they have the same cross-sectional area and are respectively connected in parallel with the solenoid valve V m8 , V m4 , V m2 , V m1 Control its work; the ratio of the lengths of these four-way capillaries is 8:4:2:1. In this embodiment, the length L of the shortest capillary m1 among the four capillaries m1 Equal to the length L of the capillary in the resistance adjustment section R half of. The diameter d of the four-way capillary m Equal to 4 times the diameter d of the largest capillary R8 in the resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com