Temperature control for sheet heating device

A technology for heating devices and paper, applied to electrical recording technology using charge graphics, equipment and instruments for electrical recording technology using charge graphics, etc., can solve problems such as failure of image fixation, and achieve the goal of preventing adhesion and suppressing adverse effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

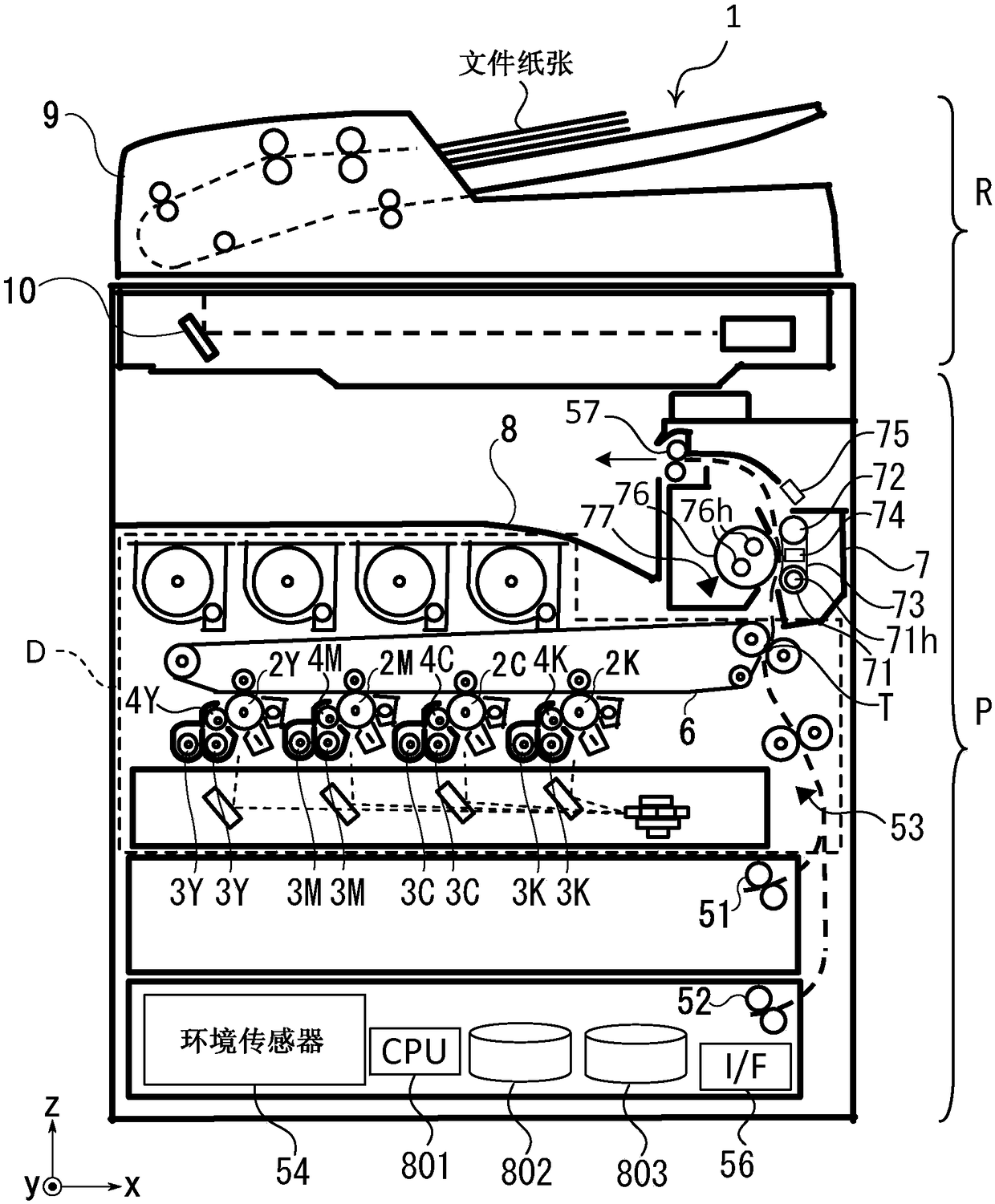

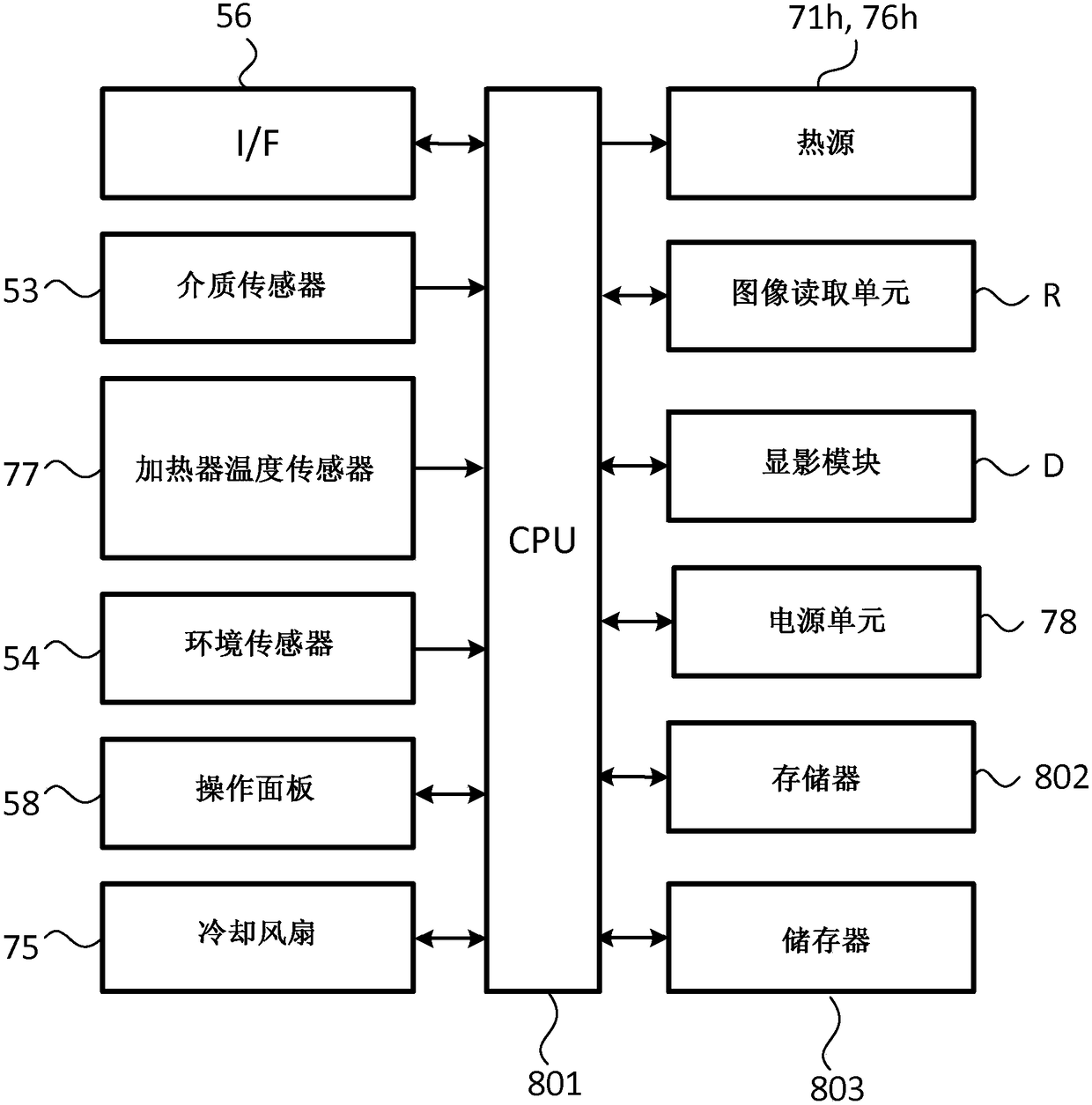

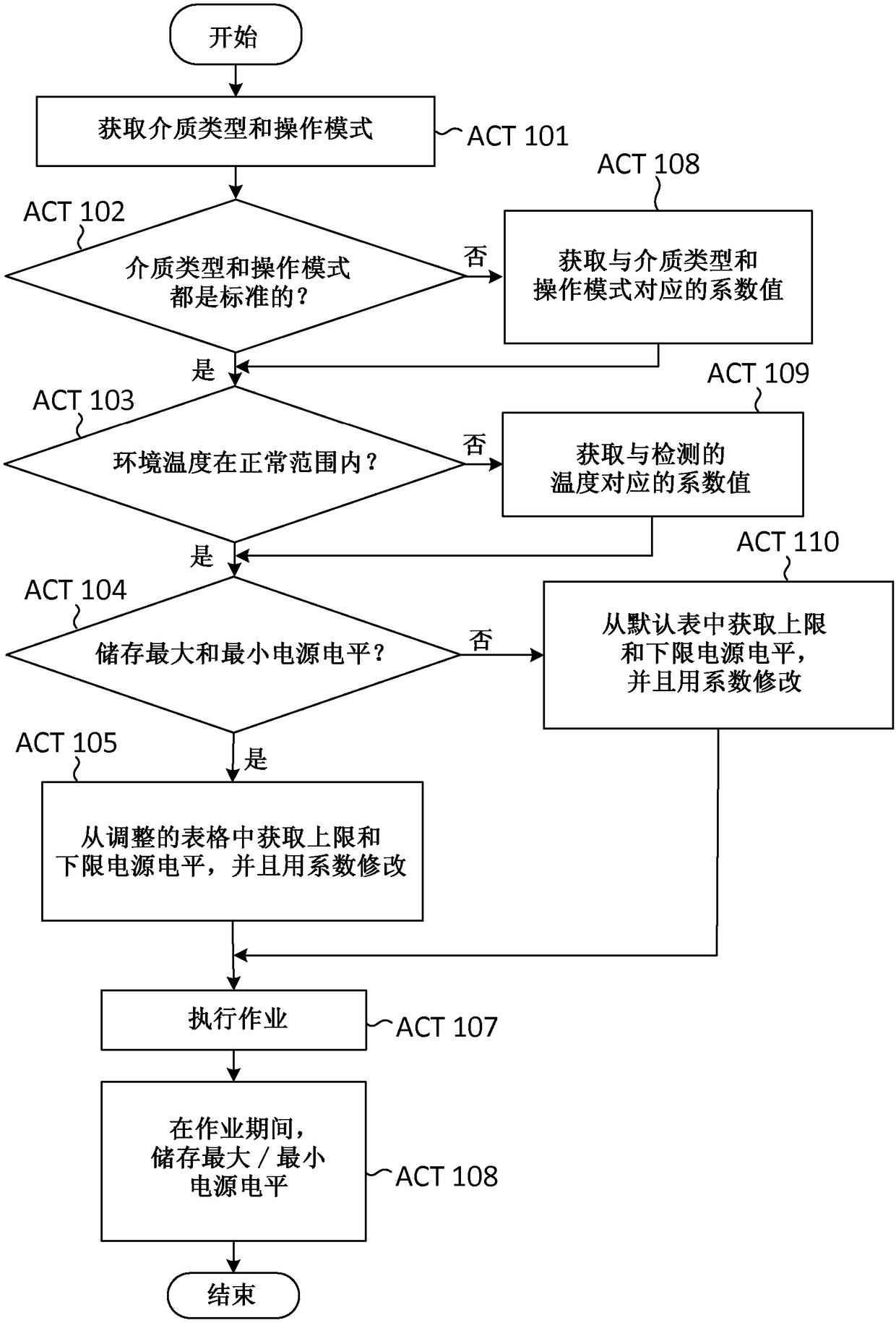

[0015] According to an aspect of the present invention, there is provided a paper heating apparatus including: a heater; a power supply for the heater; and a control unit configured to store the maximum and the minimum power level, set the initial power level of the power supply when the heater starts the paper heating job, and control the power level of the power supply during the paper heating job based on the temperature detected by the temperature sensor.

[0016] According to another aspect of the present invention, there is provided a temperature control method for a paper heating device having: a heater; a temperature sensor configured to detect a temperature of the heater; power supply for the heater. The method includes: detecting a temperature of the heater; setting an initial power level of the power supply when the heater starts the paper heating job based on the paper heating job and based on whether maximum and minimum power levels from the last paper heating job...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com