A tbm tool changing robot body structure

A technology of robot body and cutter head, which is applied in the direction of manipulator, metal processing equipment, metal processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions.

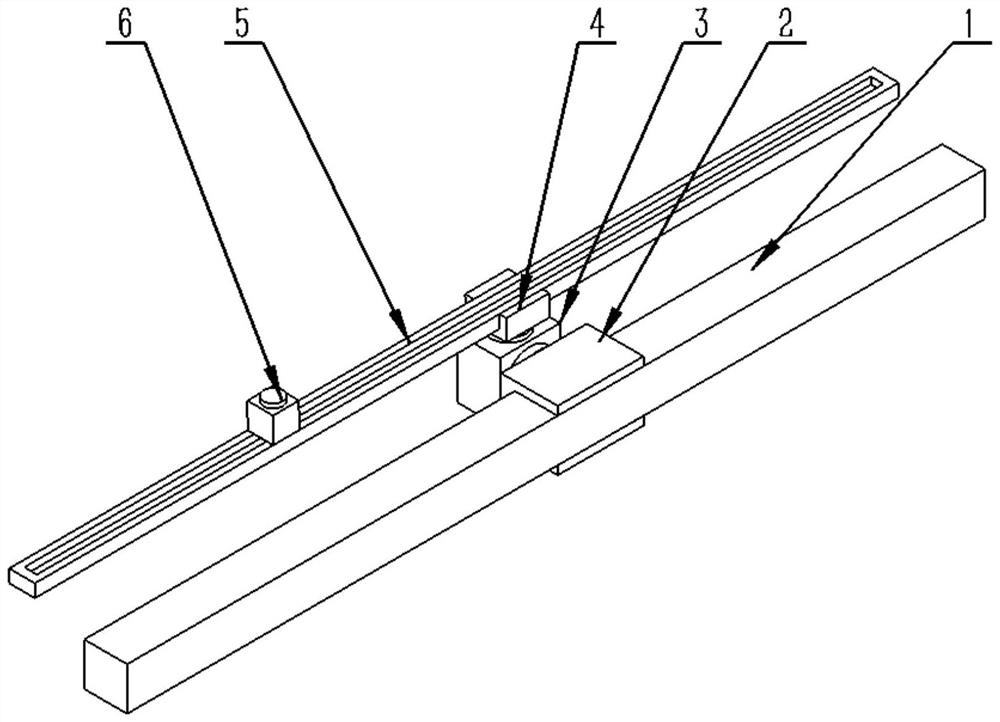

[0036] A tool changing robot body structure capable of entering into a cutter head from a TBM main beam.

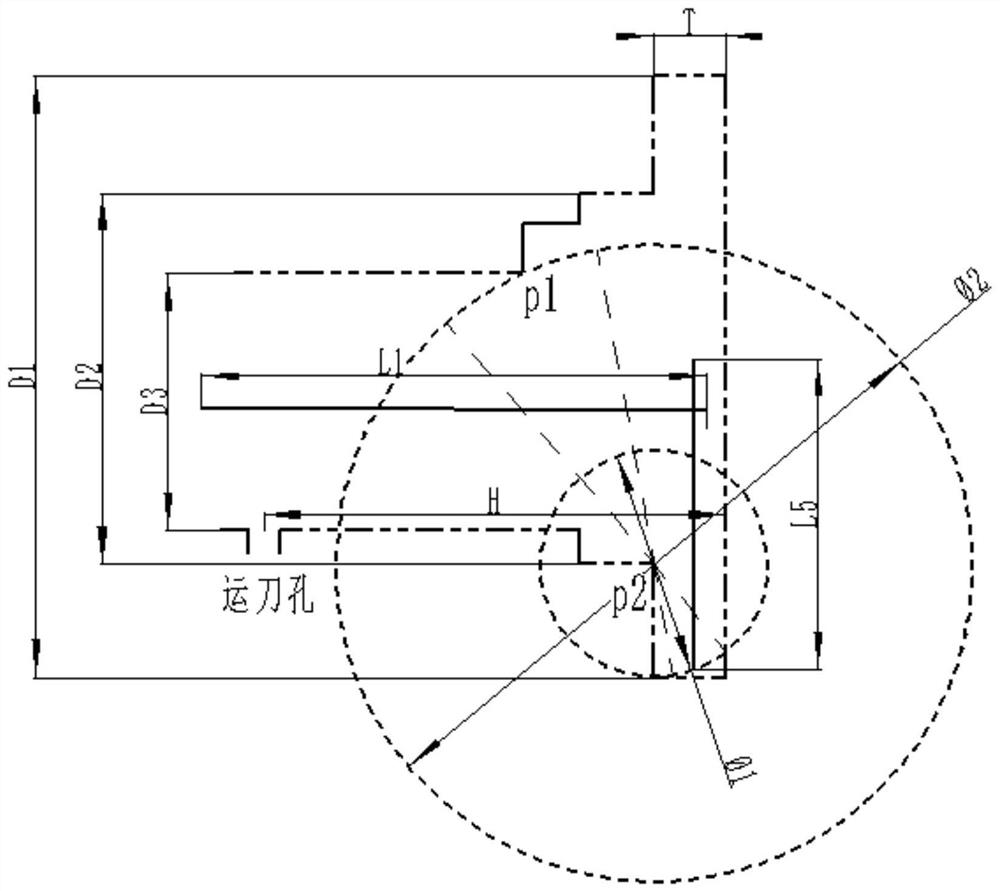

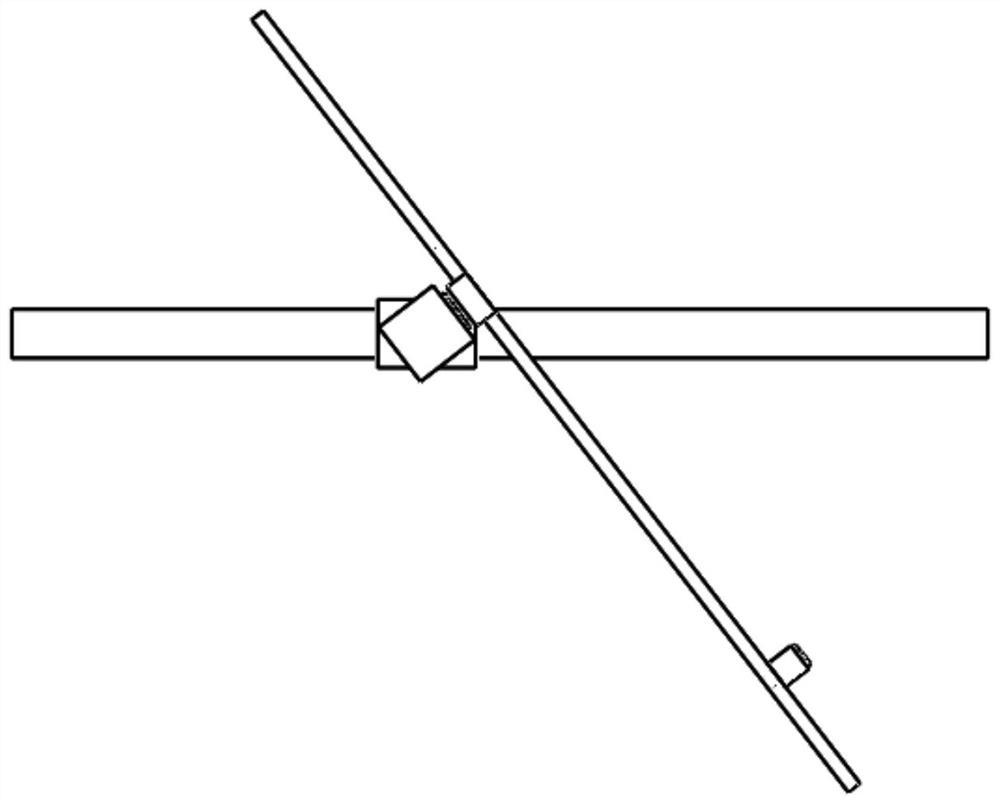

[0037] (1) When the robot is not working, the status of each part of the robot is as shown in the attached manual. figure 1 , the telescopic arm 5 is in the horizontal position; (2) When the TBM stops, the robot enters the tool change program, the sliding seat 2 and the upper and lower steering seats 3 are linked, and the telescopic arm is adjusted to the position as attached in the manual. image 3 state, and make the lower end of the telescopic arm close to the lower limit point p2 of the height of the main girder, then, maintain this posture, push the telescopic arm deep into the cutter head, and make the telescopic arm enter the maximum enveloping circle of the trajectory Then rotate the telesco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com