Single shaft controlled type five-degrees-of-freedom (DOF) miniature magnetic bearing

A single-axis control, degree of freedom technology, applied in the direction of shafts and bearings, bearings, mechanical equipment, etc., can solve the problems that cannot be applied to occasions with space restrictions, large structural size, and reduce the volume of magnetic bearings, etc., to achieve low power consumption , streamline the structure, reduce the effect of power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

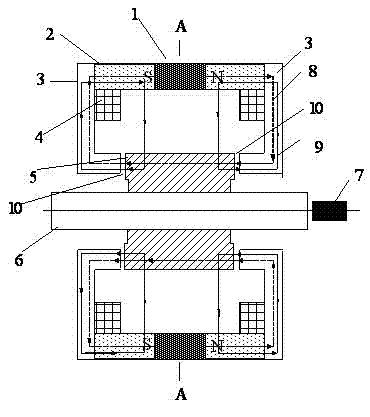

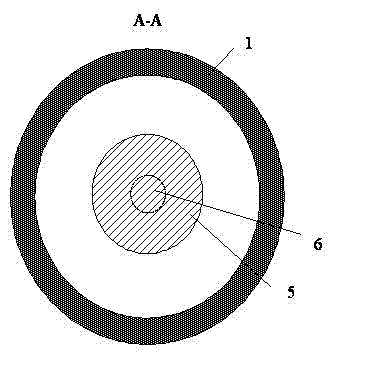

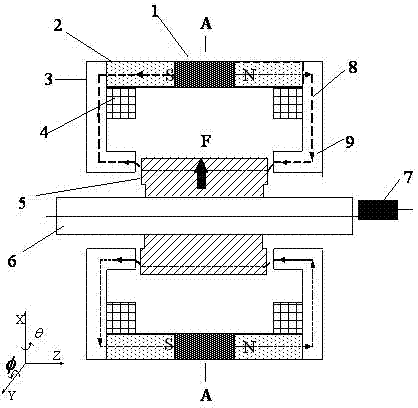

[0016] Such as figure 1 and figure 2 As shown, the present invention consists of 1 permanent magnet 1, 2 identical stator yokes 2, 2 identical flanges 3, 2 identical axial control coils 4, 1 rotor 5, 1 rotating shaft 6 and One sensor 7 is constituted. Two identical flanges 3 are both hollowly sleeved on the rotating shaft 6 and arranged left and right. The flanges 3 are commonly used in a stepped structure, and a rotor 5 and two identical stators are arranged between the two identical flanges 3 A yoke 2, a permanent magnet 1 and two identical axial control coils 4, wherein the rotor 5 is coaxially fixed on the rotating shaft 6, and a circular silicon steel sheet is laminated on the rotating shaft 6, and the two identical There is an axial air gap 10 between the inner surface of the flange 3 and the two end surfaces of the rotor 5 . A permanent magnet 1 is placed above the rotor 5, and the permanent magnet 1 is an annular permanent magnet magnetized in the axial direction, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com