Sheet conveying mechanical hand with dedusting function and assemblies thereof

A technology of mechanical components and manipulators, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problem of dust affecting the suction of suction cups, etc., and achieve the best dust removal effect, reasonable structure, and reliable control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

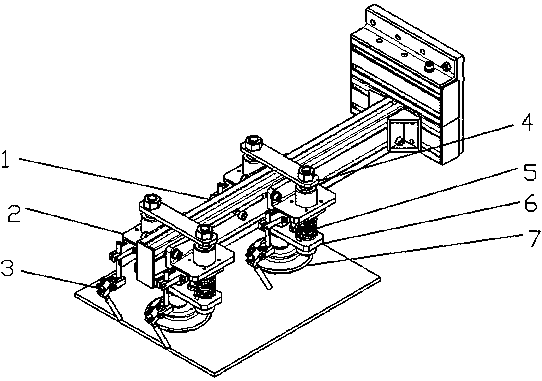

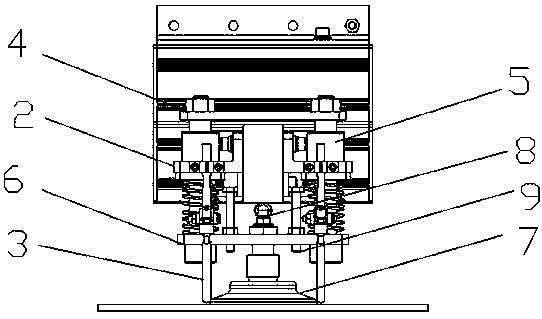

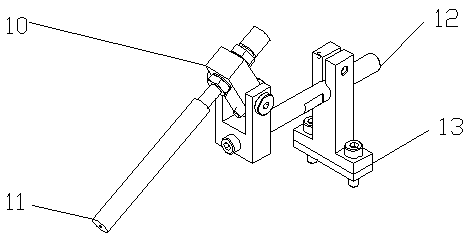

[0024] Such as figure 1 As shown, the present invention proposes a manipulator for thin plate transmission with dust removal function, including a dust removal device 3, an upper fixed plate 4, a middle fixed plate 2, a lower fixed plate 6, and a suction cup 7 through a suction cup connector 8. The suction cup 7 is fixed on the lower fixed plate 6 through the suction cup connector 8, the buffer device body is fixed between the upper fixed plate 4 and the middle fixed plate 2, and the lower end of the buffer device support rod passing through the spring is fixed on the lower fixed plate 6; the dust removal device 3 is fixed On the middle fixed plate 2, the limit body 9 is installed between the middle fixed plate 2 and the lower fixed plate 6, and the working distance between the lower fixed plate 6 and the middle fixed plate 2 is adjusted, and the dust removal device 3 is composed of the rotating device 10, The gas nozzle body 11, the long rod 12 and the fixed body 13 are compo...

Embodiment 2

[0026] A sucker-type manipulator assembly with dust removal function proposed by the present invention uses two manipulators, which are respectively arranged oppositely at the two ends of the guide rail, and the tops thereof are fixedly connected by an upper fixing plate, and there are more than two mechanical assemblies.

[0027] Such as figure 2 As shown, each suction cup manipulator includes a suction cup 7, a suction cup connector 8, a frame body 1, an upper fixing plate 4, a lower fixing plate 6, a buffer device 5, a limit body 9, a dust removal device 3, and a middle fixing plate 2. . Wherein the dedusting device is made up of rotating device 10 , gas nozzle body 11 , long rod 12 and fixed body 13 . The suction cup 7 and the suction cup connector 8 form a suction cup body, the suction cup body is fixed on the lower fixed plate 6, the buffer device 5 is multiple fixed by the upper fixed plate 4, the lower fixed plate 6 and the middle fixed plate 2, the limiter 9 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com