Photosensitive resin composition, photocuring three-dimensional printer and printing method of photocuring three-dimensional printer

A technology of 3D printers and photosensitive resins, applied in metal processing equipment, 3D object support structures, manufacturing tools, etc., can solve problems such as inability to achieve color printing and monotonous colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

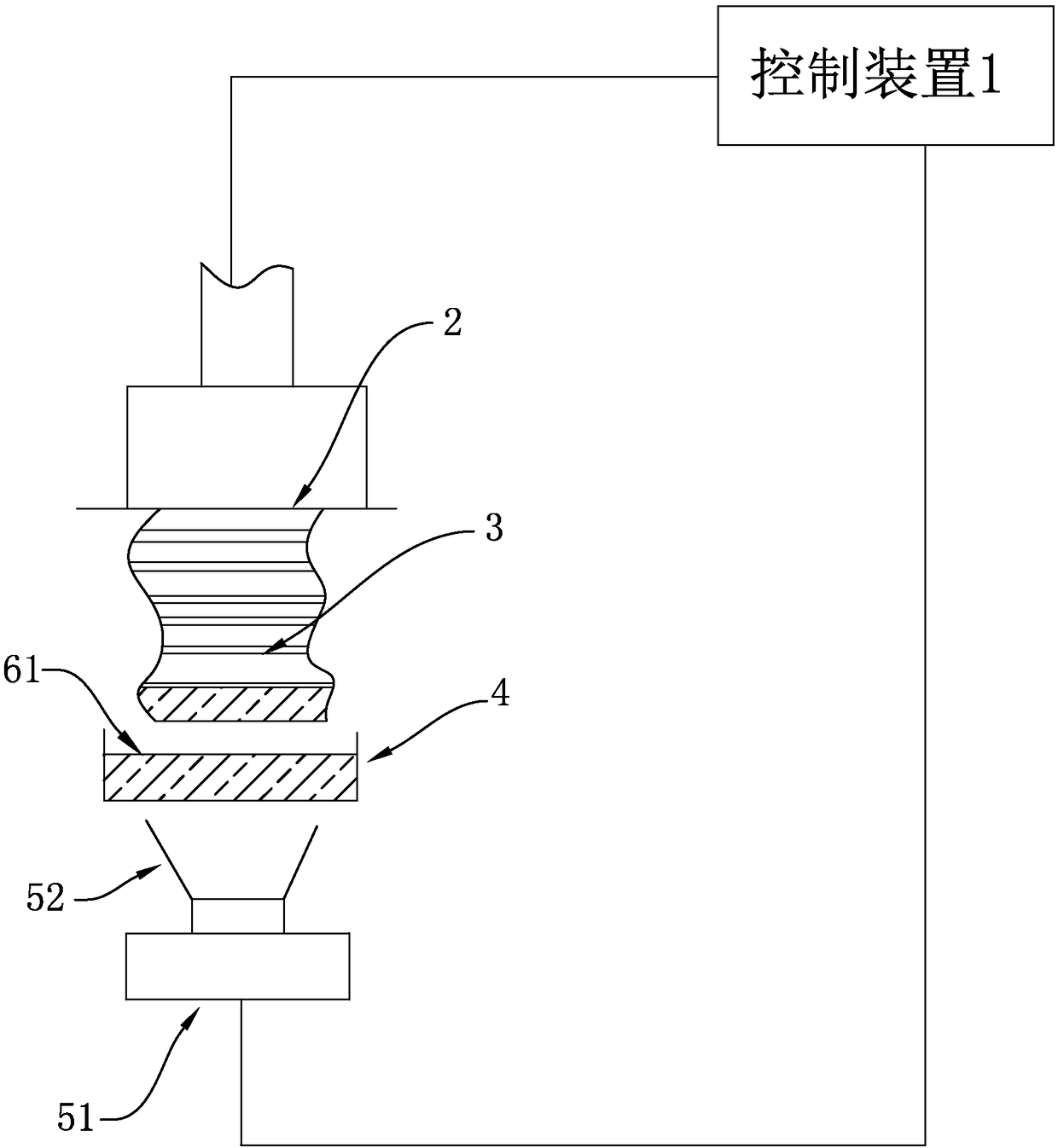

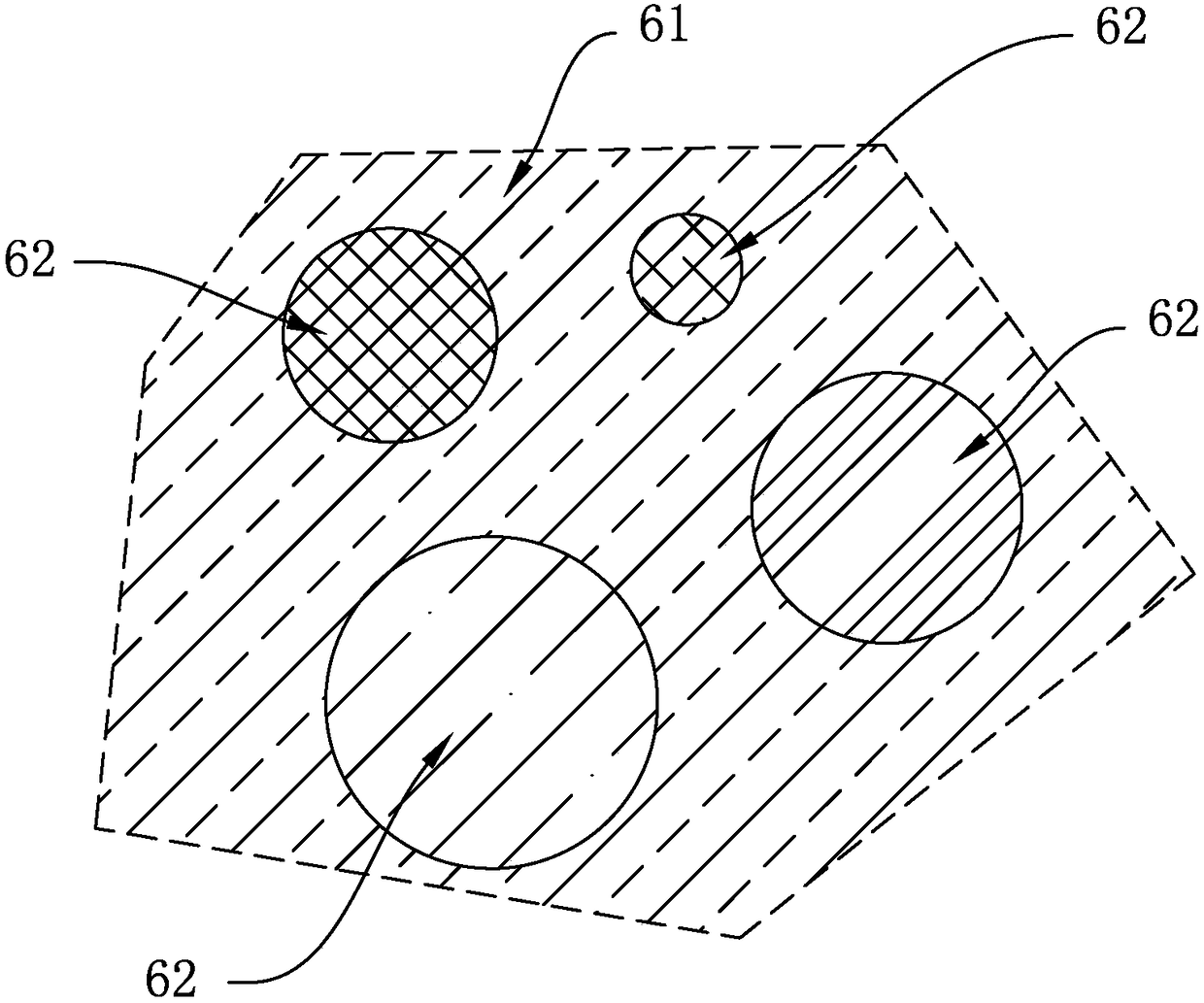

[0042] refer to figure 1 and figure 2 , the photocuring three-dimensional printer includes a control device 1, a printing platform 2, a photosensitive resin tank 4 and a light processing device 51, the printing platform 2 is located above the photosensitive resin tank 4 and is used to carry a three-dimensional object 3, and the photosensitive resin tank 4 is used to hold liquid photosensitive Resin 61, the photosensitive resin is used for curing and molding of the three-dimensional object 3, the printing platform 2 can move from low to high in the vertical direction during printing, and the light processing device 51 is located under the photosensitive resin tank 4 and can output curing light toward the printing platform 2 52. The curing light 52 can pass through the bottom of the photosensitive resin tank 4 and the photosensitive resin 61, and the photosensitive resin is cured and formed on the printing platform. The light processing device 51 can either use a fractional la...

no. 2 example

[0057] The second embodiment mainly separates the three-dimensional object 3 imaging and color imaging, so the curing light includes model curing light and color curing light, and the wavelength of the curing light can be matched and output according to the photosensitive resin and quantum dots with different particle radii.

[0058] Photocuring 3D printer printing methods include:

[0059] The light processing device 51 outputs model curing light;

[0060] Model curing light passes through the photosensitive resin;

[0061] The model curing light cures the photosensitive resin on the printing platform 2 and forms a layer of the three-dimensional object 3;

[0062] The light processing device 51 outputs color curing light to the cured photosensitive resin, so that the quantum dots of this layer of the three-dimensional object 3 are excited by the color curing light and display colors, and different particle radii display different colors according to the color curing light of d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com