Method for predicating combustion intensity of cigarettes based on detection of pressure drop

A technology of burning intensity and cigarettes, which is applied in the field of predicting the burning intensity of cigarettes based on detection pressure drop, can solve the problem of few relationship studies, achieve the effect of simplifying workload, strengthening practicability, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

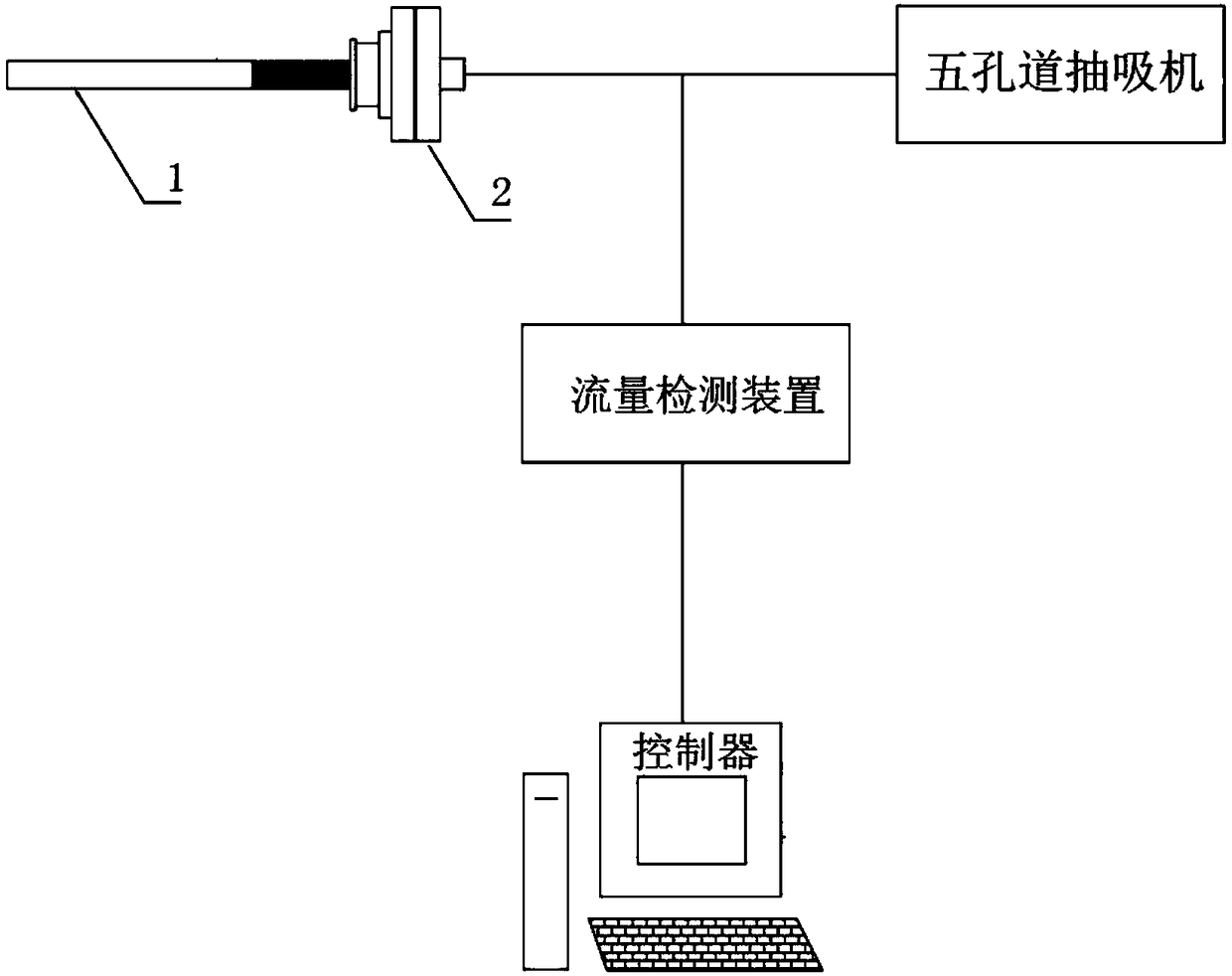

[0032] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0033] The cigarette pressure drop in the present invention refers to the average value of the cigarette system pressure drop within the duration of each puff of a cigarette under different puffing modes.

[0034] Sampling: Select 50 cigarette samples according to the conditions stipulated in GB / T 16447-2004 "Atmospheric Environment for Conditioning and Testing of Tobacco and Tobacco Products" to collect puff-by-puff pressure drop and combustion intensity under different puffing sequence .

[0035] Because the first puff of smoking and combustion of the sample is greatly affected by the cigarette lighter, the two parameter data of the second to fifth puffs of each cigarette were studied. That is to say, there are 250 sets of puff-by-puff pressure drop and corresponding puff lower surface temperature data for 50 cigarettes.

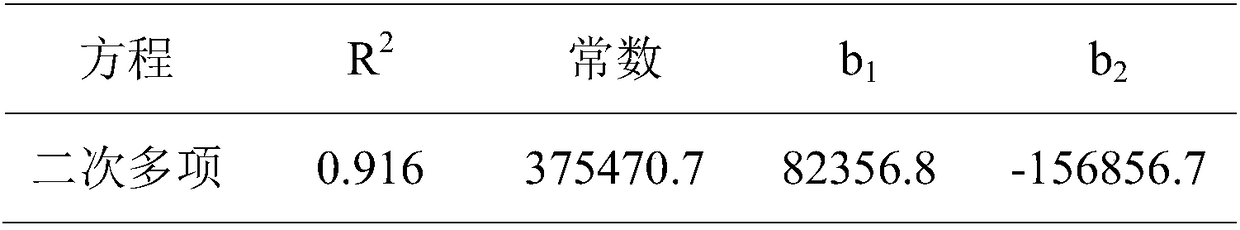

[0036] Ciga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com