A Method for Predicting Cigarette Combustion Intensity Based on Detecting Flow Field Distribution

A technology of combustion intensity and flow field distribution, which is applied in the direction of using combustion for chemical analysis, etc., can solve the problems of impact, large time cost, and heavy workload of data extraction, so as to reduce workload, wide applicability, and reduce instability effect of factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

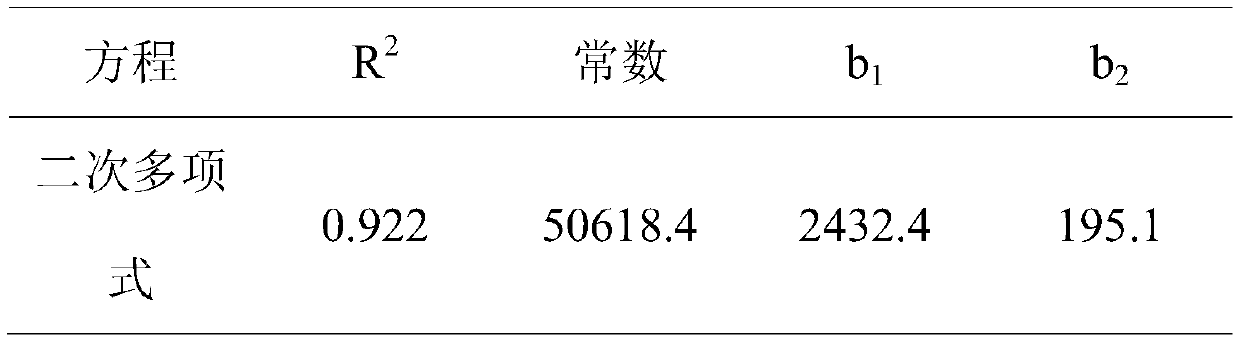

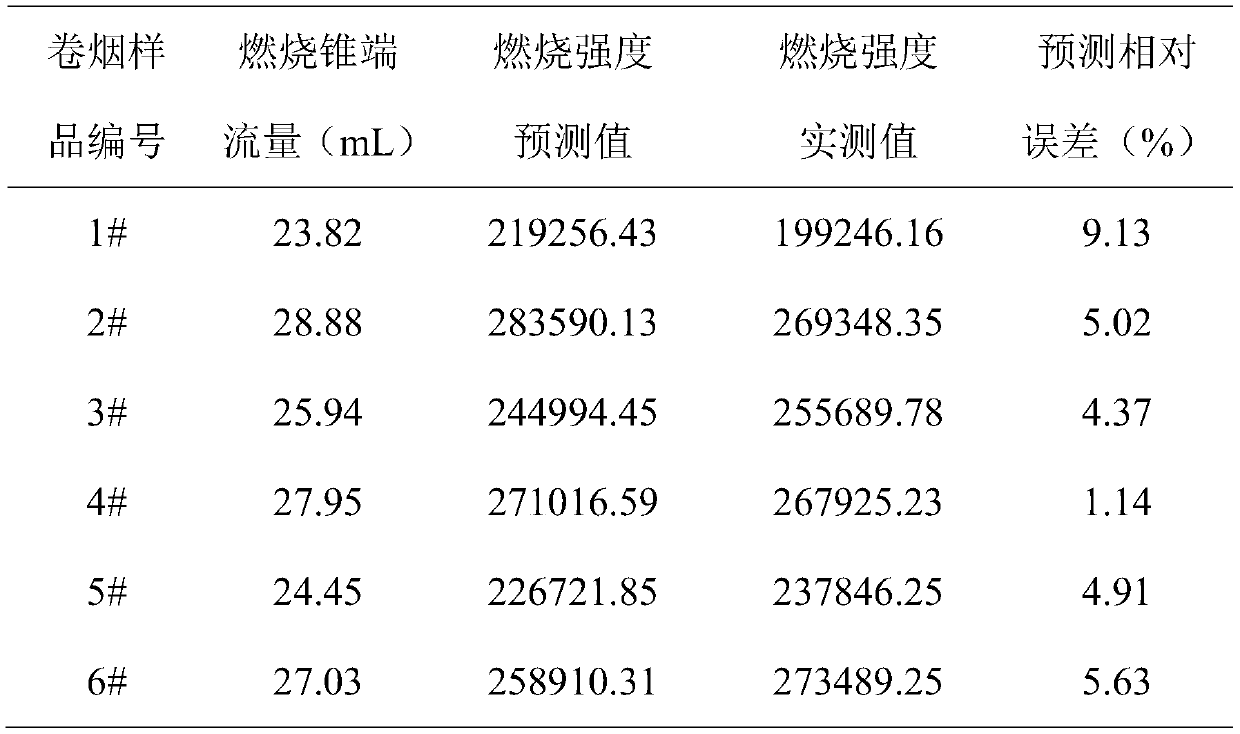

[0031] A method for predicting cigarette combustion intensity based on detection of flow field distribution, comprising the steps of:

[0032] B1. Sampling: Use the conditions specified in GB / T 16447-2004 "Atmospheric Environment for Conditioning and Testing of Tobacco and Tobacco Products" to balance and select cigarette samples for collecting flow field distribution and temperature distribution under different puffing port sequences.

[0033] Cigarette samples include mixed cigarette samples or flue-cured cigarette samples with any circumference, any length, any filter tip ventilation and any cigarette paper segment ventilation.

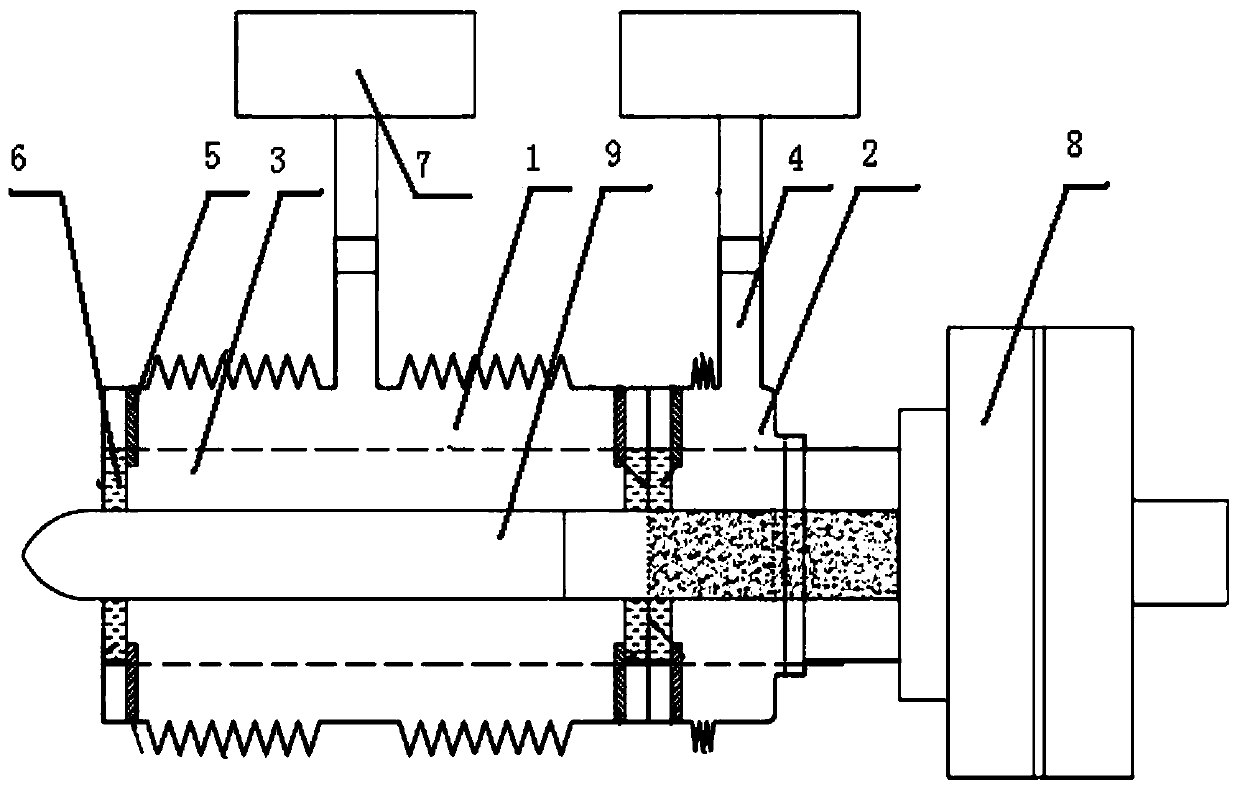

[0034] B2. Use a flow detection device to measure the air flow at the combustion cone end when the cigarette sample is sucked;

[0035] The air flow at the burning cone end of the cigarette is calculated by u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com