System for active alignment and curing of camera module

A camera module and active technology, applied in the system field, can solve the problem of low production efficiency of the camera module, save the time of active focusing, ensure product quality, and achieve the effect of high-efficiency production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

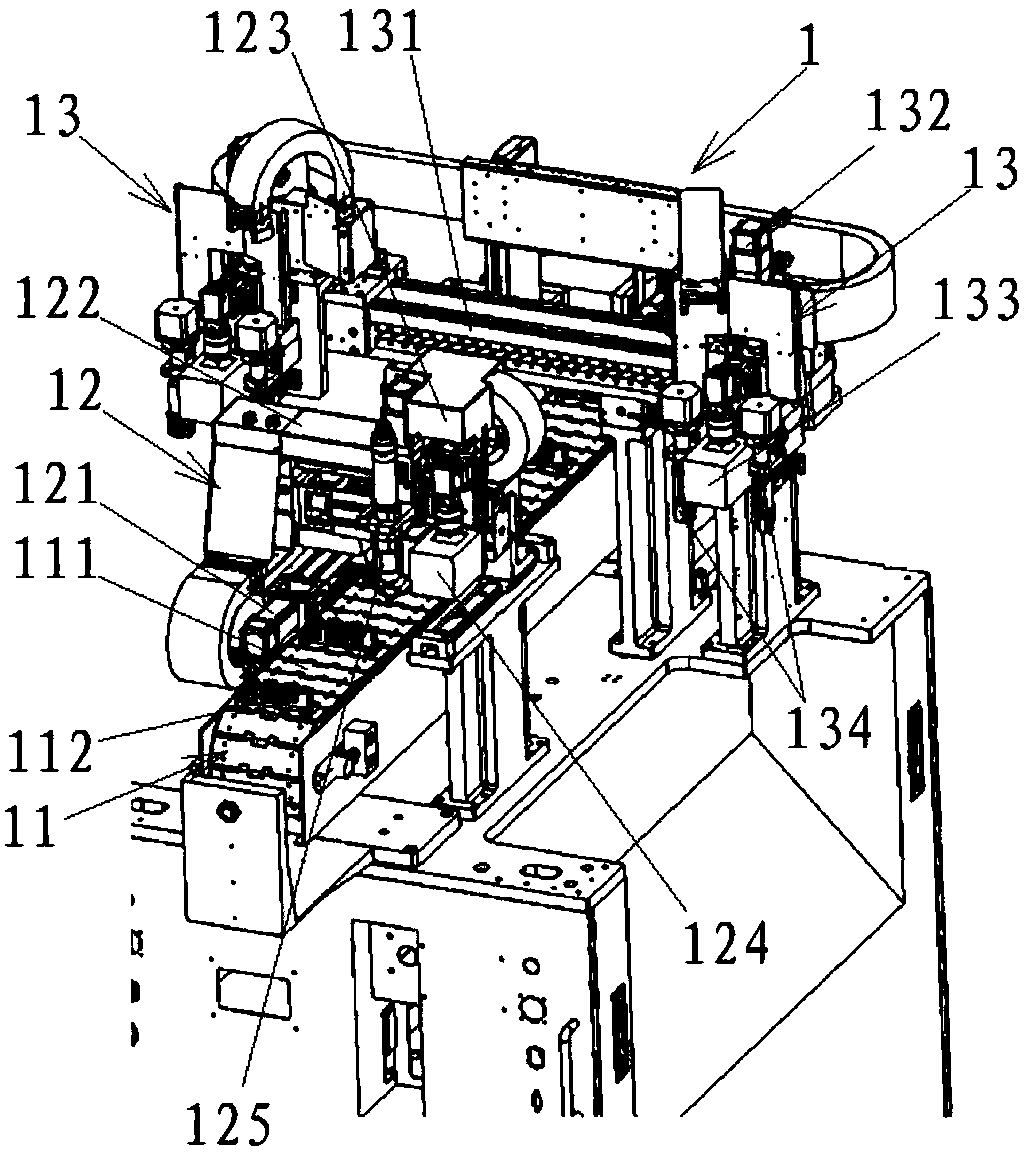

[0051] Such as figure 2 As shown, according to an embodiment of the present invention, the dispensing device 12 includes: a first X-axis drive mechanism 121, a first Y-axis mechanism 122, a first Z-axis mechanism 123, a first visual measurement mechanism 124 and a glue application mechanism 125. In this embodiment, the first Y-axis mechanism 122 is supported by the first X-axis drive mechanism 121 , and the first Z-axis mechanism 123 is supported by the first Y-axis mechanism 122 . The first visual measuring mechanism 124 and the gluing mechanism 125 are respectively fixedly connected with the first Z-axis mechanism 123 . In this embodiment, the first visual measurement mechanism 124 and the gluing mechanism 125 are arranged side by side.

[0052] Such as figure 2 As shown, according to an embodiment of the present invention, the first pick-and-place device 13 includes a second Y-axis mechanism 131 , a second Z-axis mechanism 132 , a second visual measurement mechanism 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com