Anti-jamming jewel-crafting fixture

A fixture and jewelry technology, applied in the field of processing fixtures, can solve the problems of property loss, easily pinched objects, difficult to control, etc., and achieve the effect of simple manual operation, convenient free adjustment, and prevention of being pinched.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

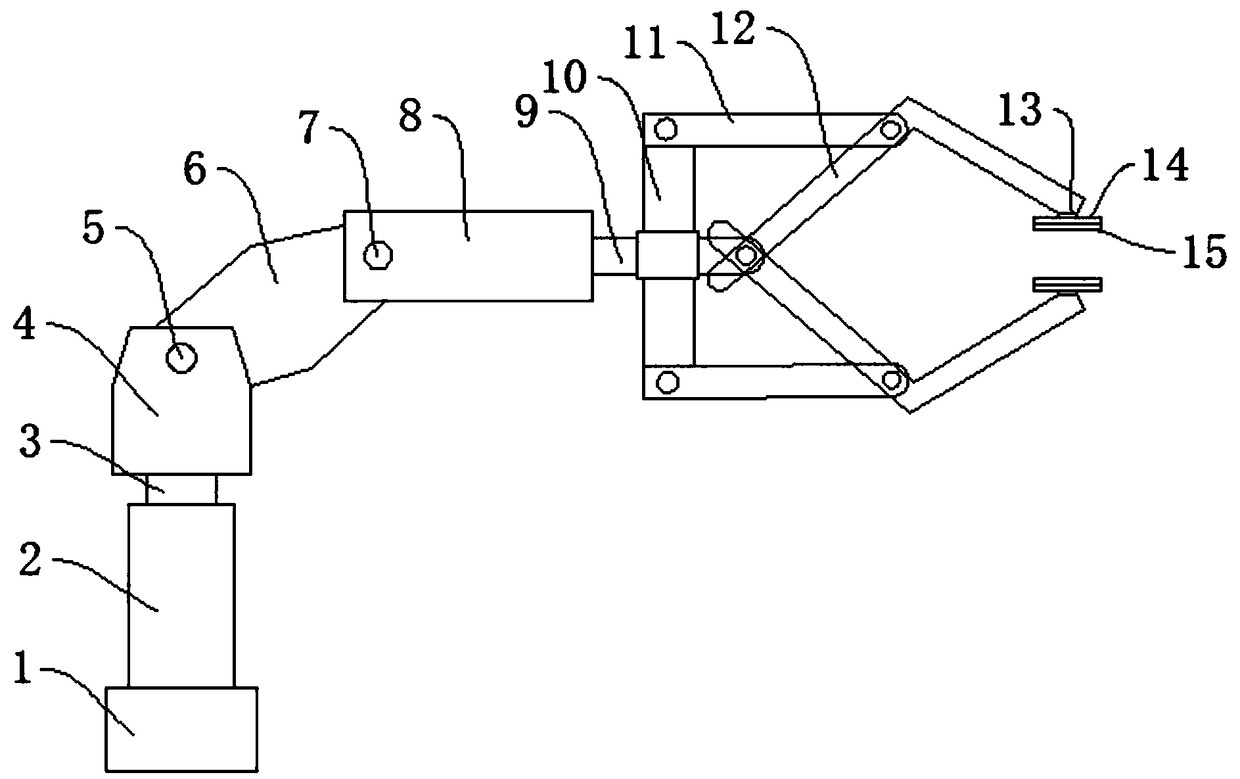

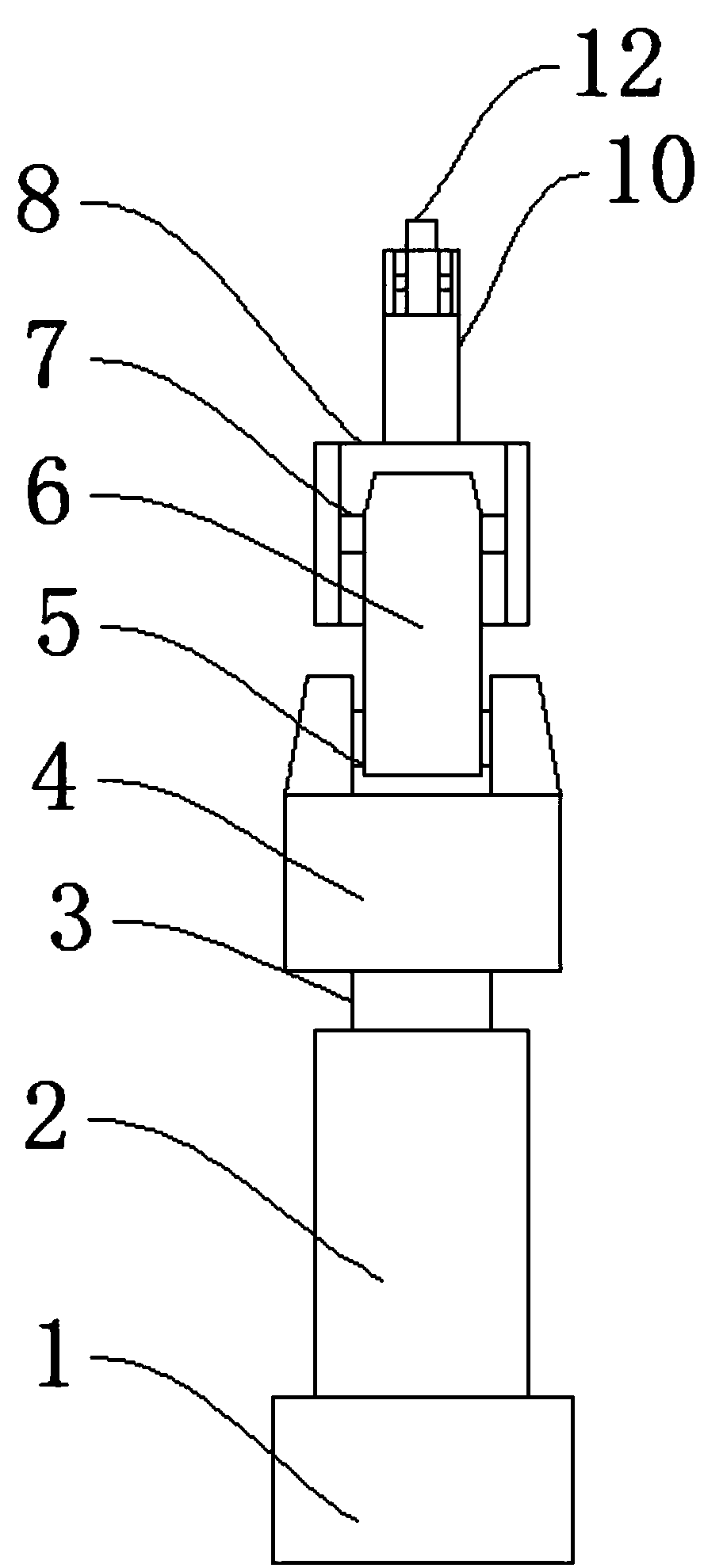

[0019] The present invention will be further described below in conjunction with accompanying drawing:

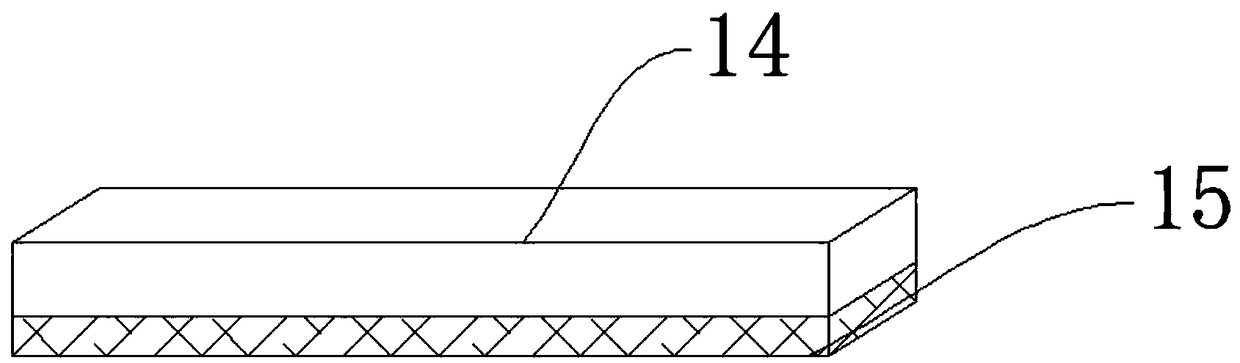

[0020] Such as Figure 1-Figure 3 As shown, an anti-pinching fixture for jewelry processing includes a base 1, a support column 2, a rotating frame 4, and a clamp 14. The upper end of the base 1 is provided with a support column 2, and the support column 2 acts as a supporting device. The support column 2 The upper end is provided with a rotating shaft 3, and the rotating shaft 3 plays the role of driving the rotating frame 4 to rotate. A rotating shaft 5, the first rotating shaft 5 plays the role of driving the first moment arm 6 to rotate, the first moment arm 5 is provided with a first moment arm 6 outside, the first moment arm 6 plays the role of driving the second rotating shaft 7, the first moment arm One end of 6 is provided with a second moment arm 8, and the second moment arm 8 plays the role of adjusting the vertical angle, which is transmitted to the rotating ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com