Seat cushion core and manufacturing method thereof

A back cushion and seat technology, which is applied in the field of seat back cushion core and its preparation, can solve the problems of increased cost and high price of the back cushion, and achieve the effects of reducing material cost, absorbing the pressure of the tailbone, and saving costs and expenses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

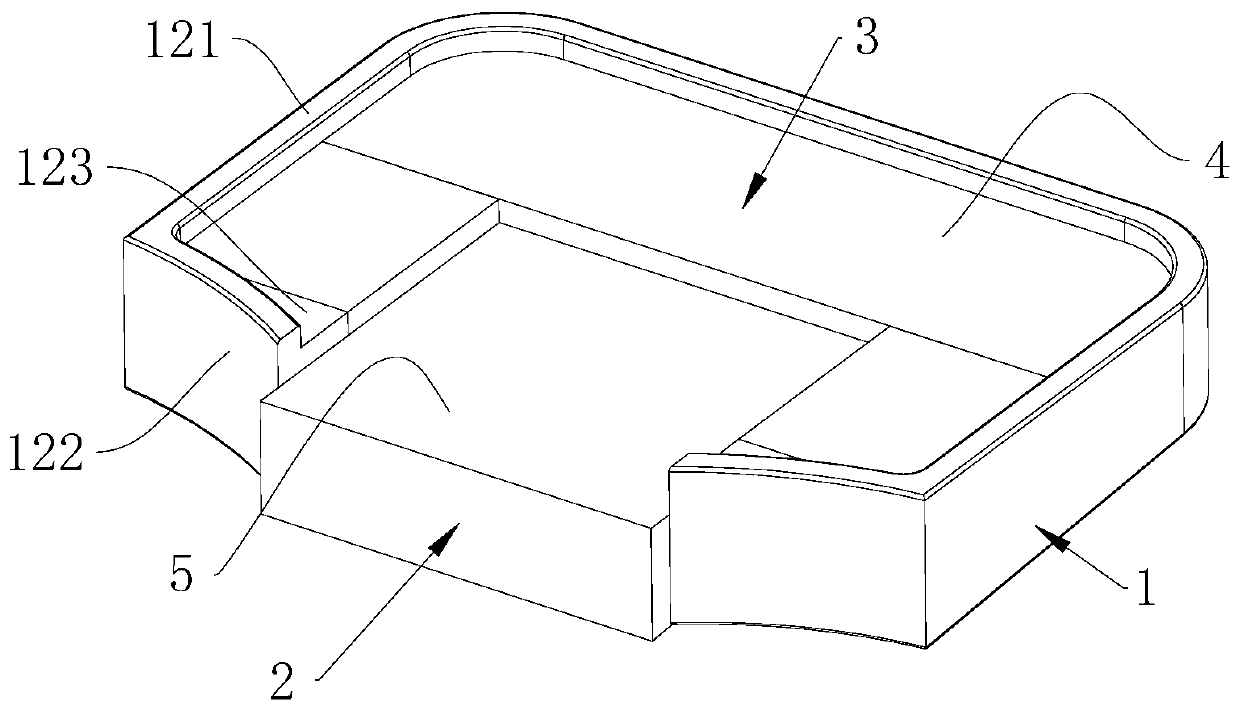

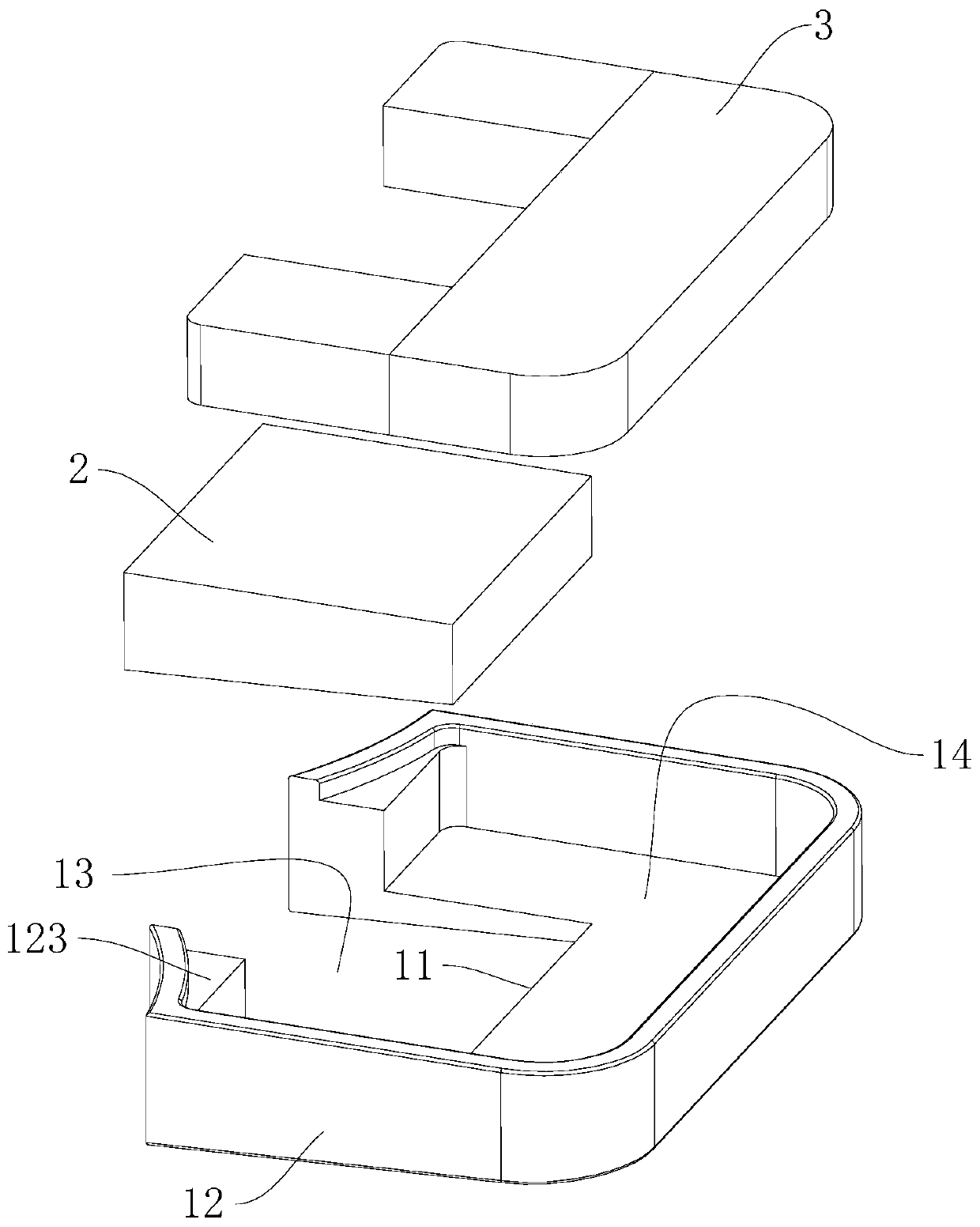

[0038] see figure 1 with figure 2 , a seat back cushion core, including polyurethane shaped cotton skeleton 1 and embedded in the polyurethane shaped cotton skeleton 1 in the sponge core 2 and U-shaped pearl cotton outer core 3. Wherein, the hardness of the polyurethane shaped cotton skeleton 1 is greater than the hardness of the U-shaped pearl cotton outer core 3 , and the hardness of the U-shaped pearl cotton outer core 3 is greater than the hardness of the sponge inner core 2 .

[0039] see figure 1 with figure 2 , The polyurethane shaped cotton skeleton 1 includes a frame body 11 and a flange 12 that is arranged around the frame body 11 in the circumferential direction. The frame body 11 is provided with an installation channel 13 penetrating through the sides and upper and lower surfaces of the frame body 11 . The sponge inner core 2 is fixedly embedded in the installation through groove 13 by an adhesive. The opening of the installation channel 13 is opened on the...

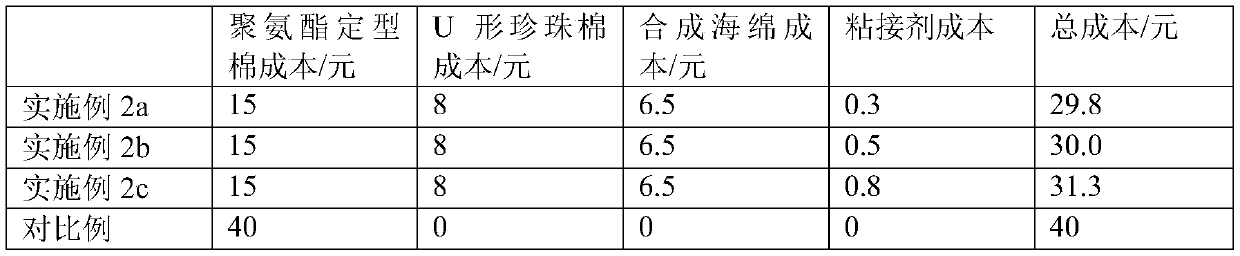

Embodiment 2a

[0043] A method for manufacturing a seat back cushion core, comprising the steps of:

[0044] Step1, foam molding polyurethane stereotyped cotton skeleton 1, U-shaped pearl cotton outer core 3 and sponge inner core 2 through mold foaming;

[0045] Step2, coat the commercially available acrylic elastic adhesive in the installation channel 13 and the U-shaped channel of the U-shaped pearl cotton outer core 3, purchased from Shanghai Derun Petrochemical Co., Ltd.;

[0046] Step 3: Embed the sponge inner core 2 in the installation channel 13, and embed the U-shaped pearl cotton outer core 3 in the U-shaped channel. After the adhesive is cured, the seat back cushion core is obtained.

Embodiment 2b

[0048] A method for manufacturing a seat back cushion core, comprising the steps of:

[0049] Step1, foam molding polyurethane stereotyped cotton skeleton 1, U-shaped pearl cotton outer core 3 and sponge inner core 2 through mold foaming;

[0050] Step2, apply commercially available epoxy resin rigid glue in the installation channel 13 and the U-shaped channel of the U-shaped pearl cotton outer core 3, purchased from Shanghai Derun Petrochemical Co., Ltd.;

[0051] Step 3: Embed the sponge inner core 2 in the installation channel 13, and embed the U-shaped pearl cotton outer core 3 in the U-shaped channel. After the adhesive is cured, the seat back cushion core is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com