Folding industrial container hoisting device

A technology for hoisting equipment and containers, which is applied in the field of folding industrial container hoisting equipment, and can solve problems such as unsuitability for hoisting industrial containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

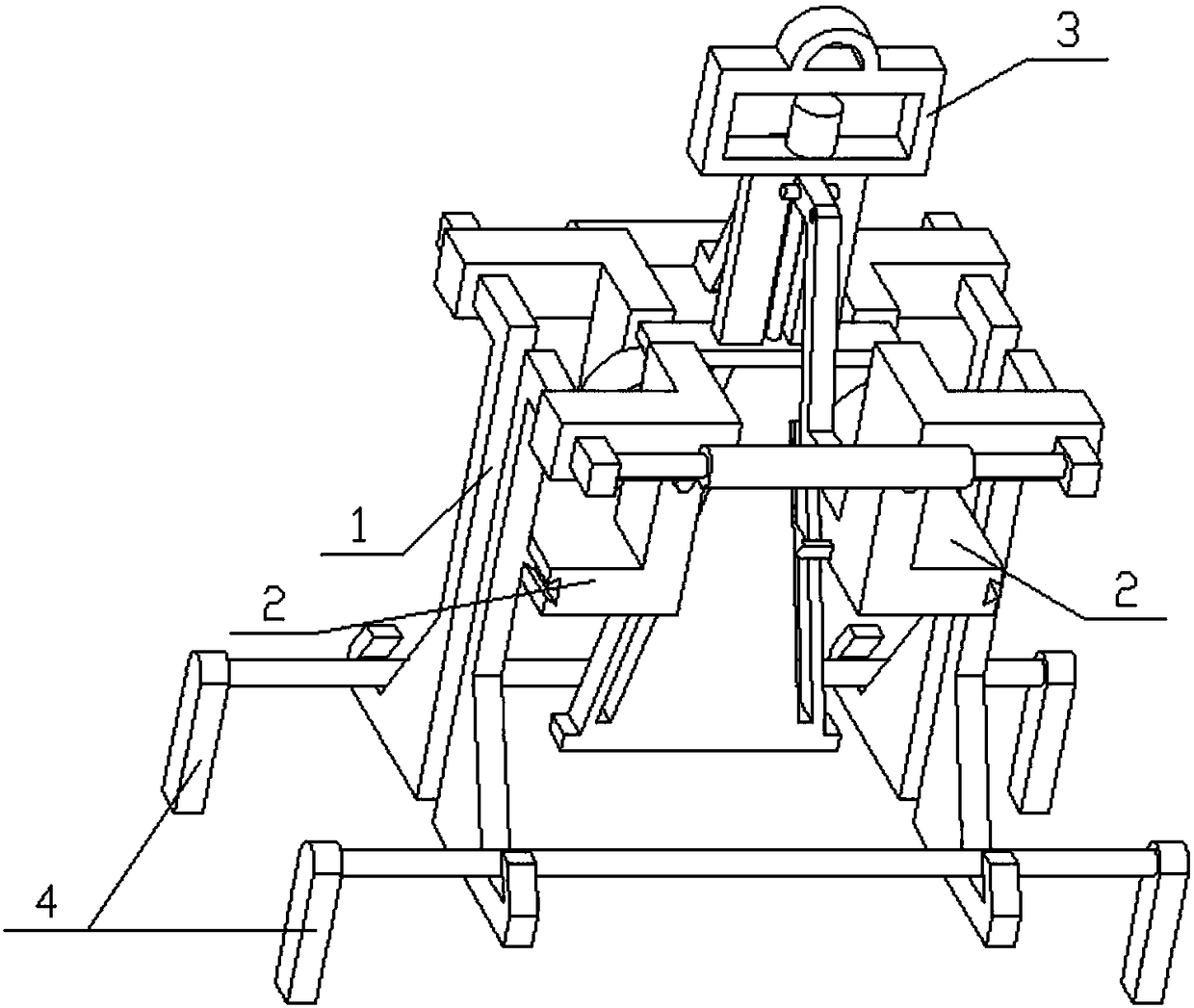

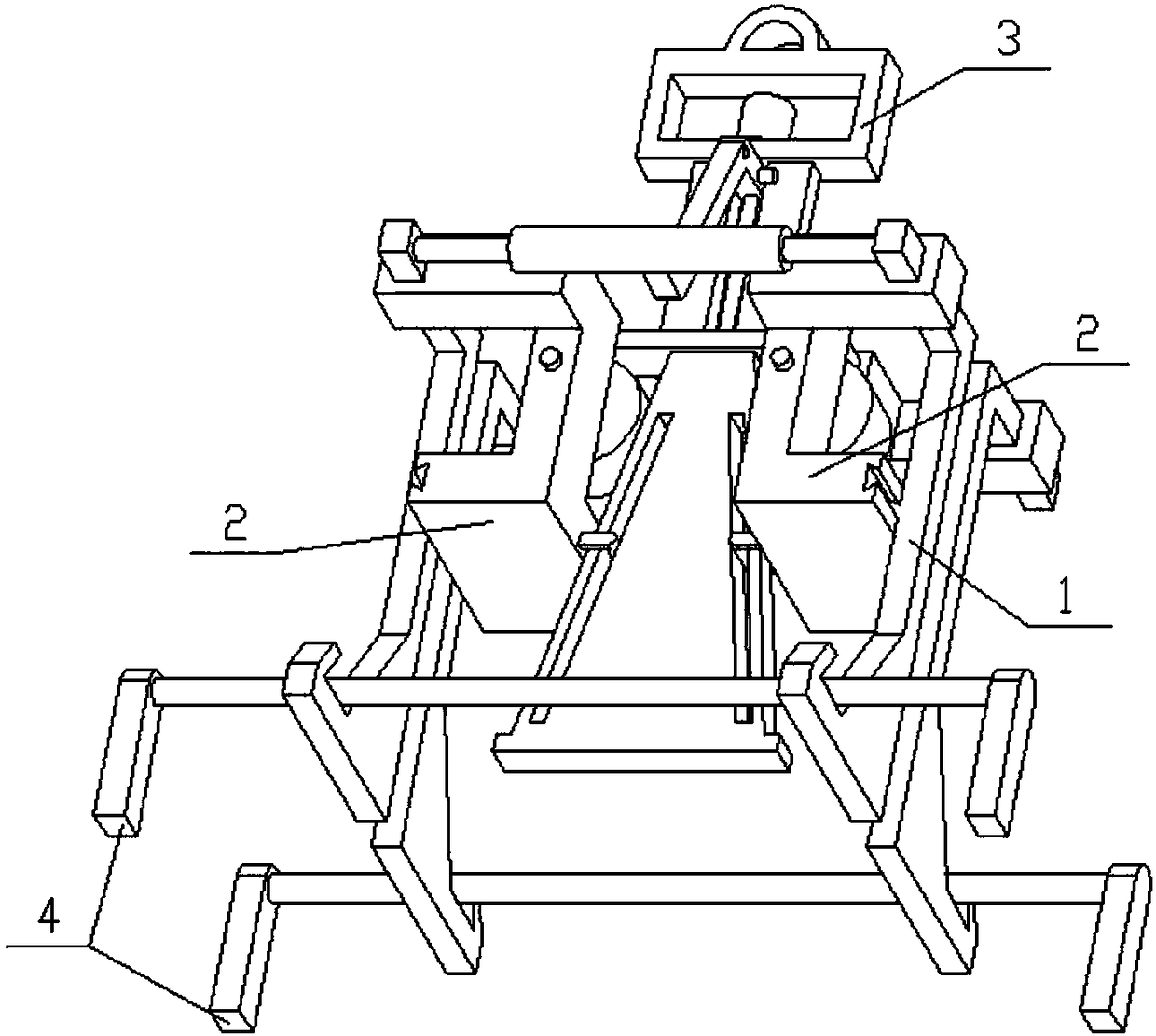

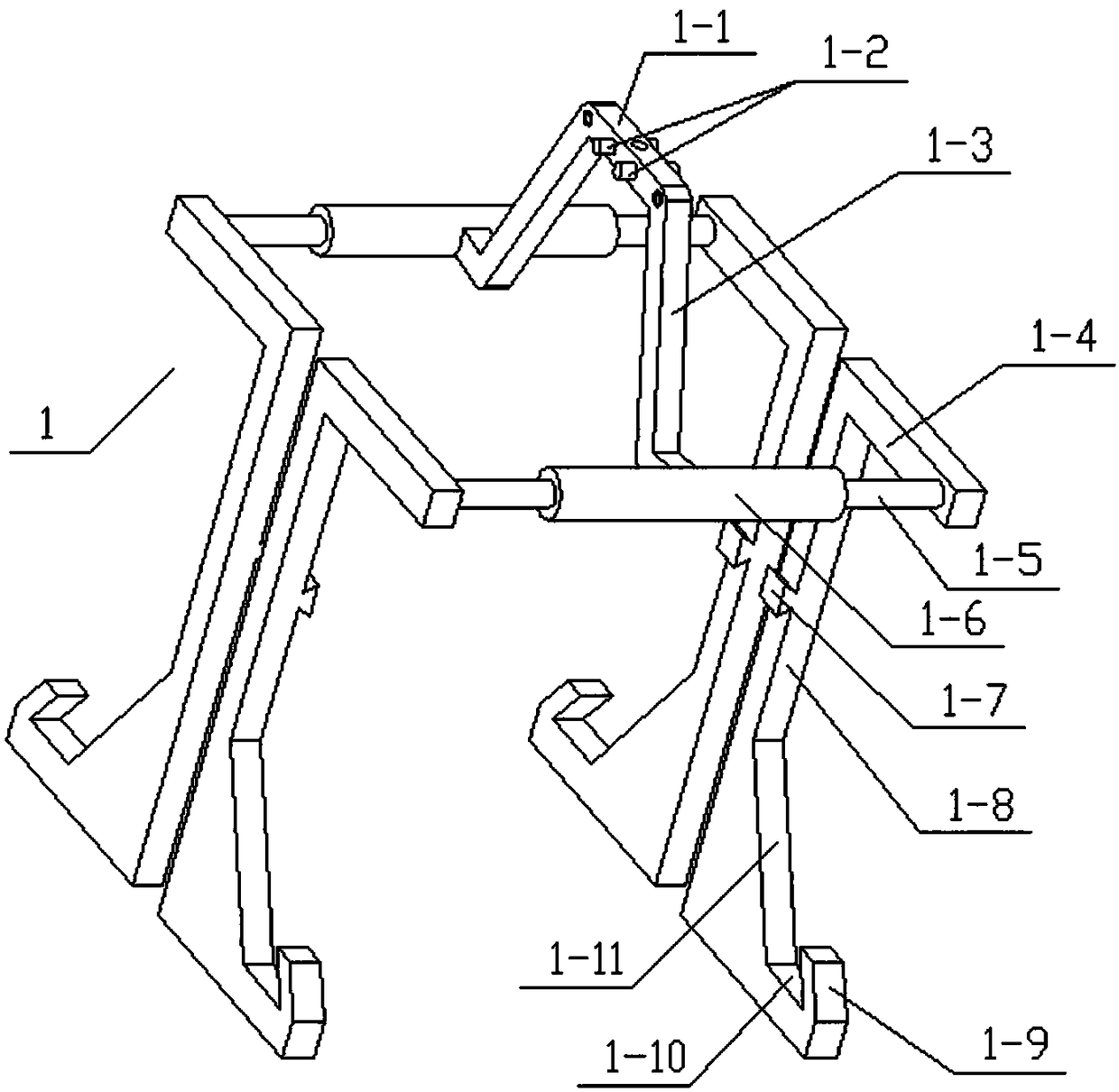

[0023] Combine below Figure 1-8 To illustrate this embodiment, the present invention relates to an industrial appliance, more specifically, a folding industrial container hoisting equipment, which includes a hanger body 1, a side seat body 2 and a hoisting assembly 3, passing rectangular frames 3-5 through When the crane is pulled up, the two L-shaped hangers 1-8 at the left end and the two L-shaped hangers 1-8 at the right end automatically expand outward, and the two L-shaped hangers 1-8 at the front end and the two at the back end The L-shaped hangers 1-8 can also be expanded outward, so that the container can be hoisted by four L-shaped hangers 1-8.

[0024] The hanger body 1 includes a middle crossbar 1-1, a limit cylinder 1-2, an inclined connecting rod 1-3, an upper horizontal sliding rod 1-4, an insert cylinder 1-5, a hollow cylinder 1-6 and L-shaped hanger 1-8, the middle position of the middle cross bar 1-1 is provided with a vertical threaded hole, the middle end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com