Preparation technology of composite digital line crepe

A preparation process and line technology, which is applied in the field of preparation of composite digital line crepe, to achieve new pattern design methods and new fabric effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

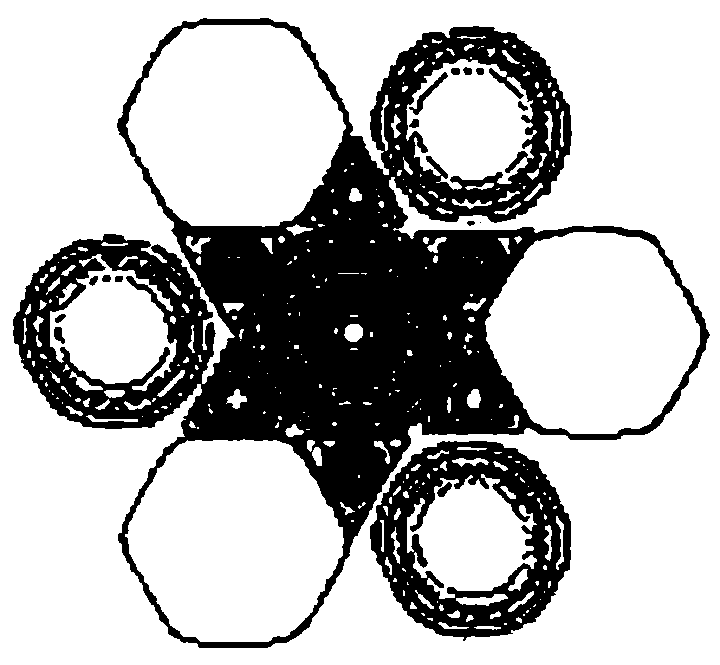

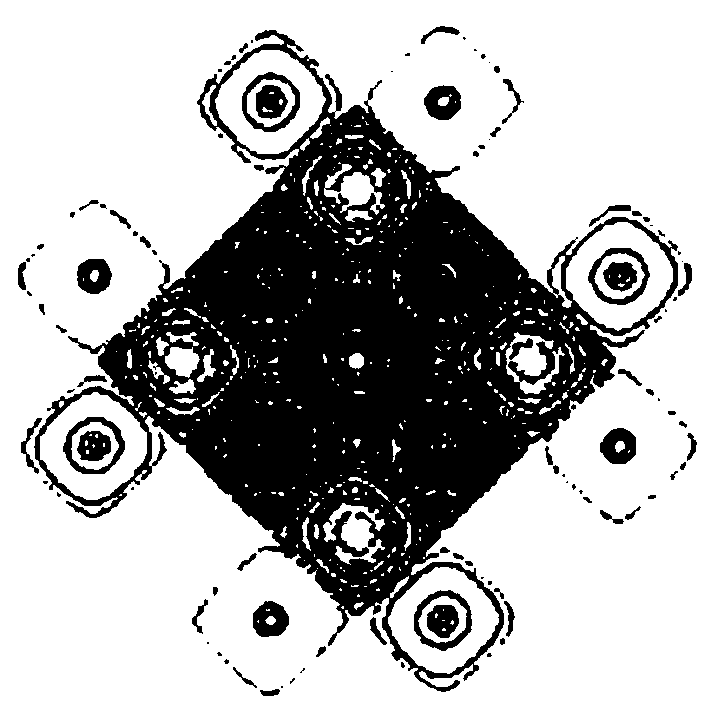

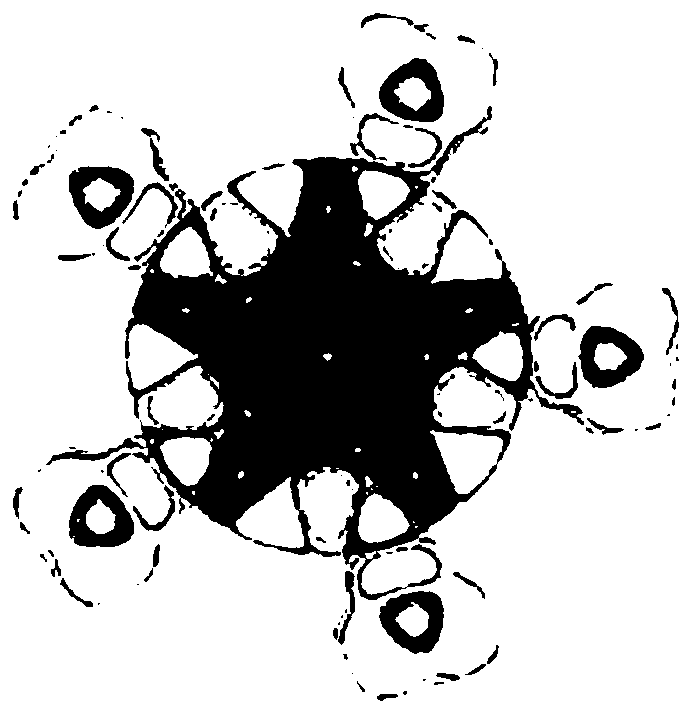

Image

Examples

Embodiment 1

[0082] The product specifications and technological process of jacquard silk fabric of sangbo satin are as follows:

[0083] 1. Product specifications

[0084] Product name: 14362

[0085] Finished product specifications: width 106-104; warp density 1163 threads / 10cm; weft density 460 threads / cm; 72 grams / square meter (16.5 mm).

[0086] Warp: 2 / 20 / 22 D Mulberry Silk.

[0087] Weft: (2 / 20 / 22D·18T / S+20 / 22 D) 18T / Z.

[0088] Floral weave: 5 pieces of satin on the front and back.

[0089] 2. Process flow

[0090] Warp: picking→soaking→drying→turning silk→warping;

[0091] Weft: picking→soaking→drying→rewinding→threading→twisting→setting→re-threading→re-twisting→resetting→weft coiling;

[0092] Warp and weft: weaving→hanging chain→finishing.

[0093] The technical link between digital line crepe and traditional crepe jacquard fabrics, the method of preparing and forming composite digital line crepe:

[0094] 1. Generate graphics with closely arranged lines. It is determin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com