Flexible substrate fixing method and flexible substrate

A technology of flexible substrates and fixing methods, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of defective products, low efficiency, waste of substrates, etc., and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

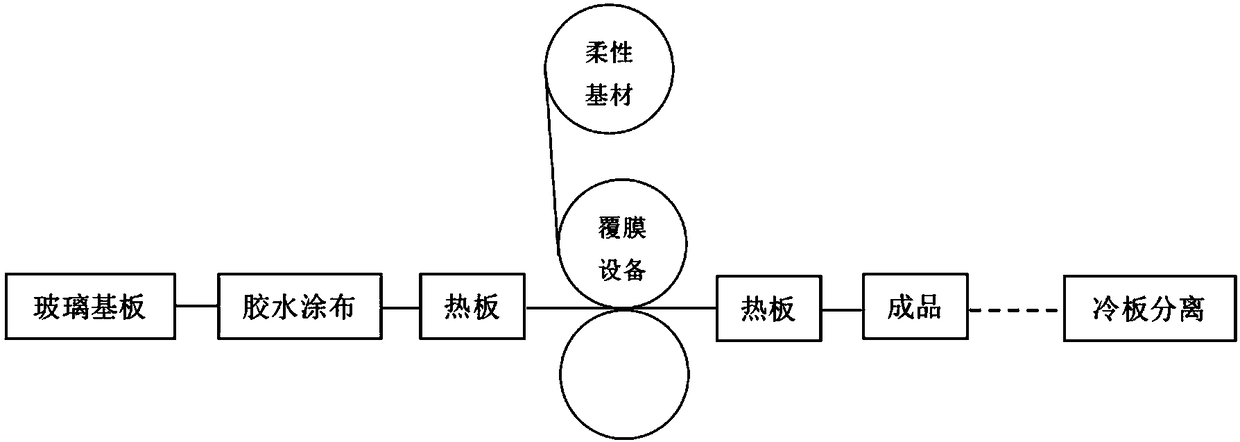

[0028] Such as figure 1 As shown, the present embodiment provides a flexible substrate fixing method, which includes the following steps:

[0029] Step 1. Select a carrier substrate that is convenient for the subsequent processing of the flexible substrate 3;

[0030] Step 2. Apply a layer of temperature-control glue 2 evenly on the carrier substrate;

[0031] Step 3: heating the carrying substrate to make the temperature-controlled glue 2 viscous, and attaching the flexible substrate 3 to the carrying substrate;

[0032] Step 4: Continue the heat treatment until the flexible base material 3 is bonded to the carrier substrate to obtain a fixed flexible base material 3 .

[0033] This embodiment provides a flexible substrate 3 fixing method that is easy to operate and can be mass-produced automatically, which can solve the mass production of flexible devices without modifying existing equipment, and at the same time improve the processing efficiency of flexible devices and sa...

Embodiment 2

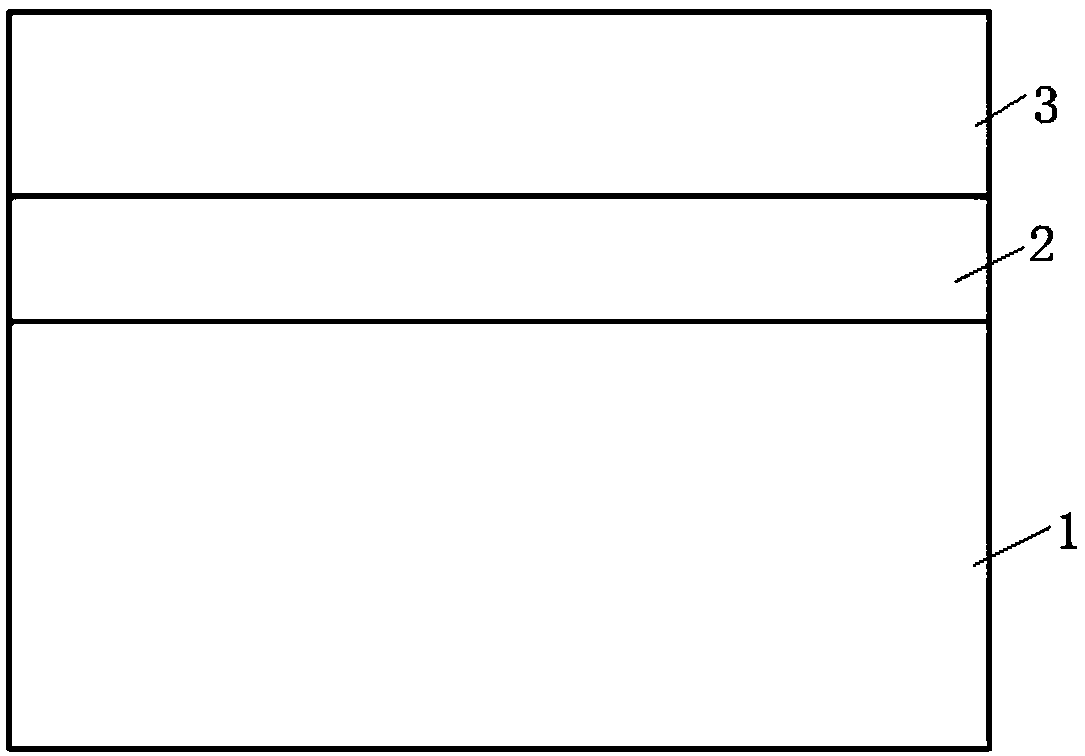

[0044] On the basis of Embodiment 1, this embodiment further provides a flexible substrate, which includes a glass substrate 1, a flexible substrate 3, and a temperature-controlled glue 2 arranged between them, and adopts the method described in Embodiment 1. The flexible base material 3 fixing methods are fixed into one body, such as figure 2 shown.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap