Vent adaptor assemblies, methods of making the same, methods of using the same, and urinary drainage bag systems using the same

An adapter and drainage bag technology, applied in the fields of ultrasonic welding of sintered porous PTFE filters to ventilation adapter assemblies, urinary drainage bag systems, and ventilation adapter assemblies, can solve problems such as hindering accurate measurement of intra-abdominal pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

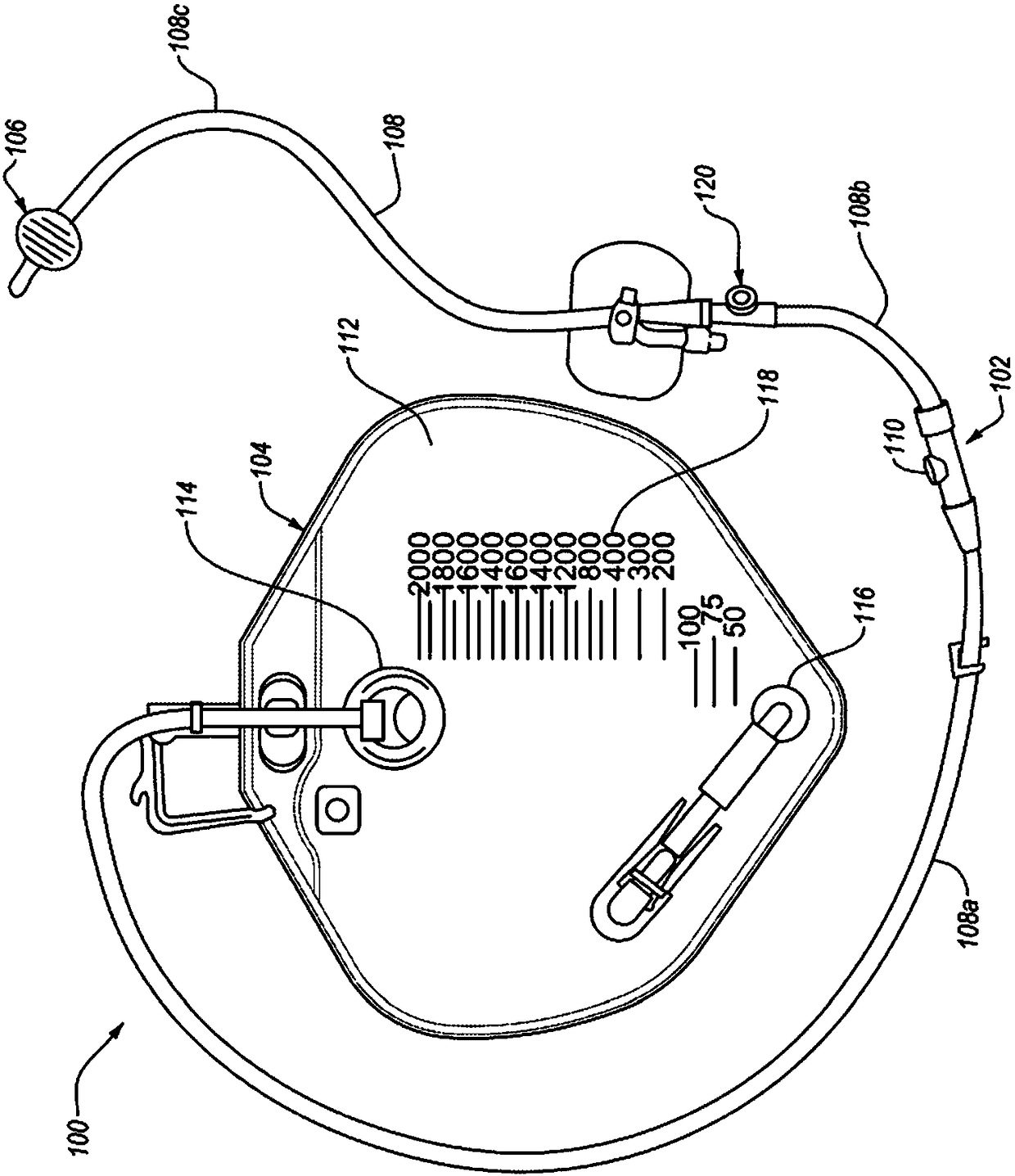

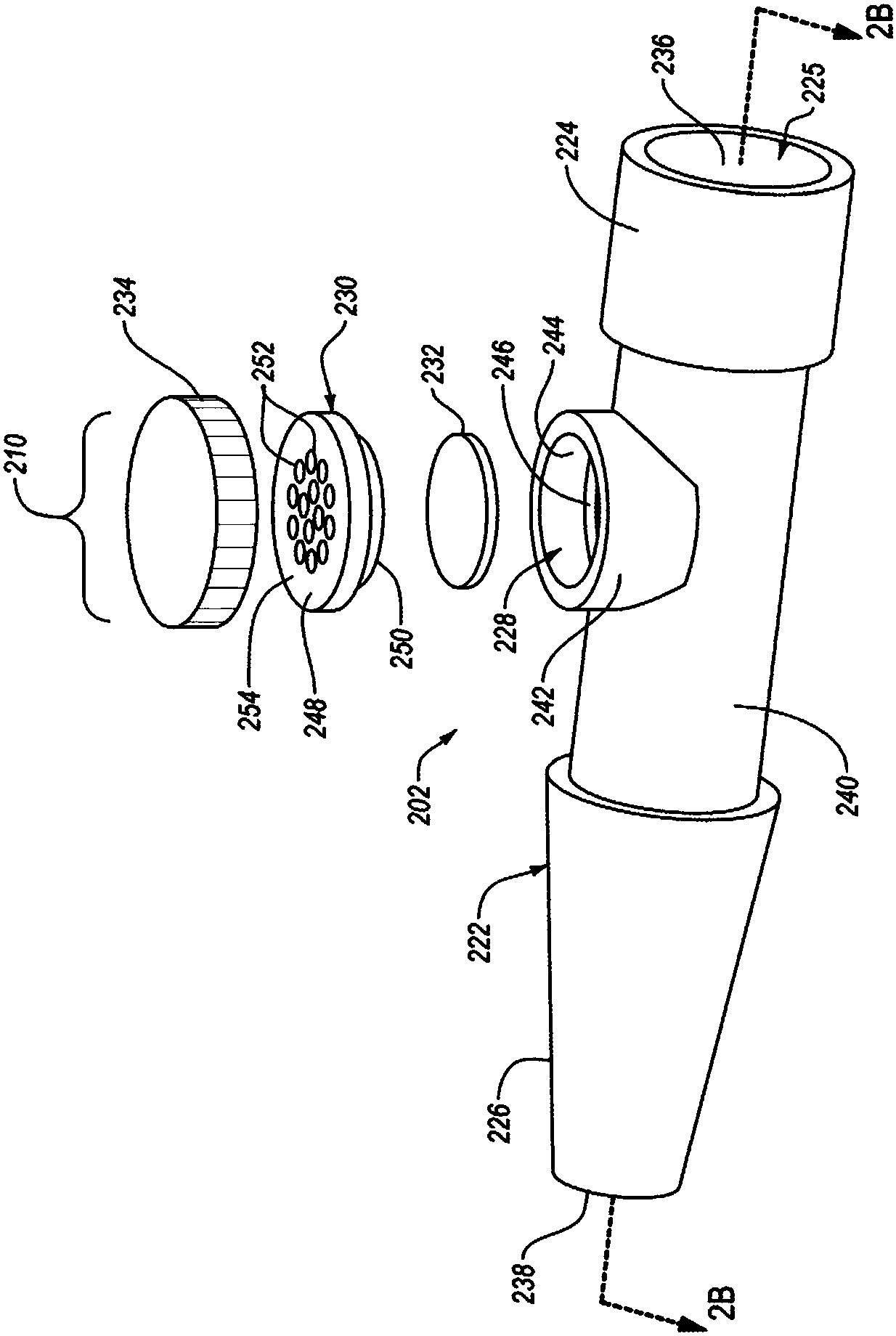

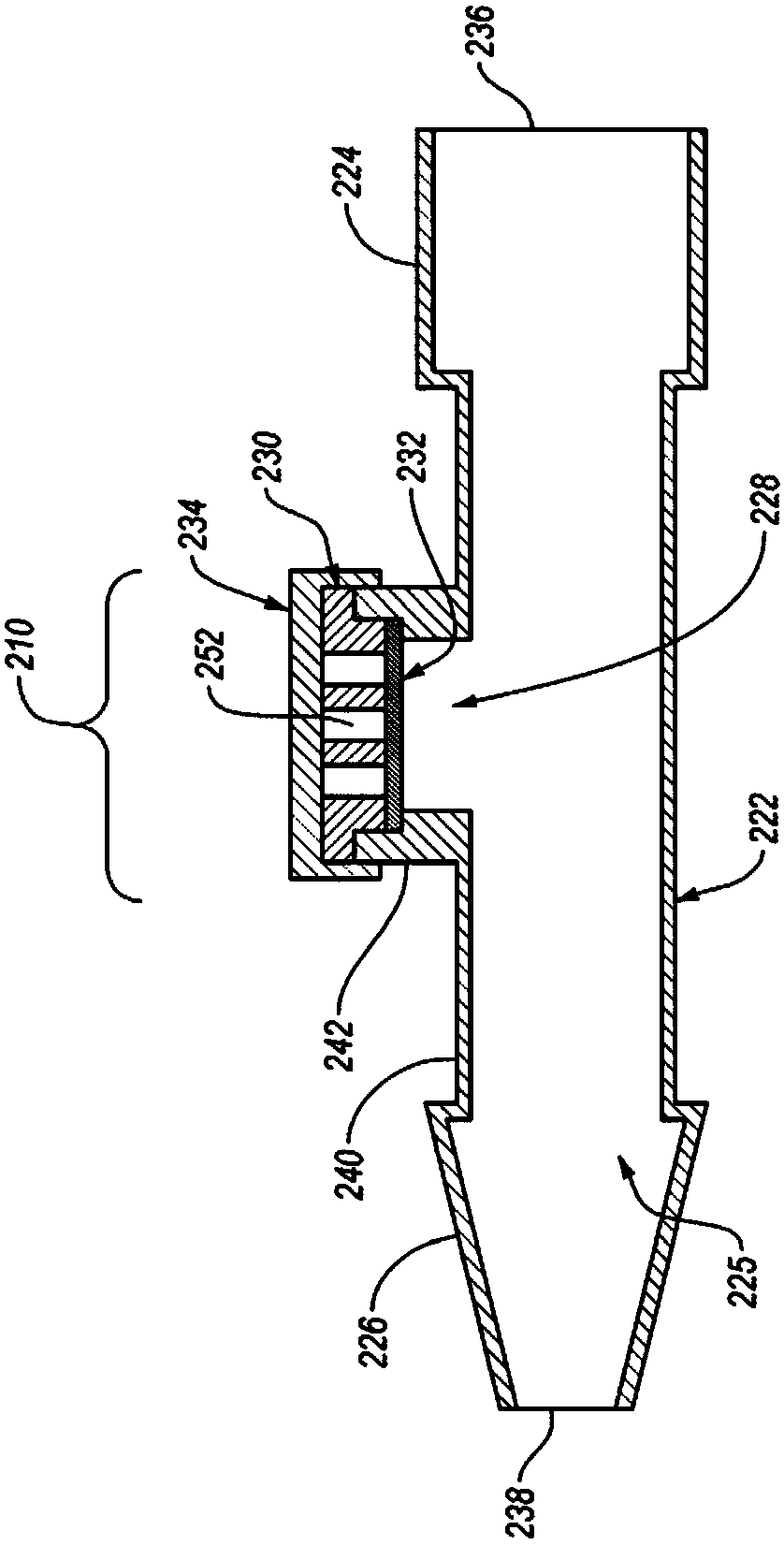

[0025] Embodiments disclosed herein relate to ventilation adapter assemblies including filters, methods of making such ventilation adapter assemblies, methods of using such ventilation adapter assemblies, and urinary drainage bag systems including such ventilation adapter assemblies. A ventilation adapter assembly disclosed herein includes a filter configured to allow gas (eg, air) to flow therethrough while at least partially preventing fluid (eg, urine) retained in the ventilation adapter assembly from flowing therethrough. In an embodiment, the filter comprises a sintered porous PTFE filter, which may be in the form of a membrane ultrasonically welded directly to the polycarbonate component (eg, the non-porous polycarbonate component) of the vent adapter assembly.

[0026] While many of the embodiments disclosed herein discuss a ventilation adapter assembly in relation to a urinary drainage bag system (eg, a Foley catheterization system), it should be understood that the ven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com