Method for forming bezel pattern using inkjet printing

一种喷墨印刷、边框的技术,应用在印刷的后处理、印刷、复制/标记方法等方向,能够解决边框图案和基板界面处短路等问题,达到优异粘合强度、优异性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

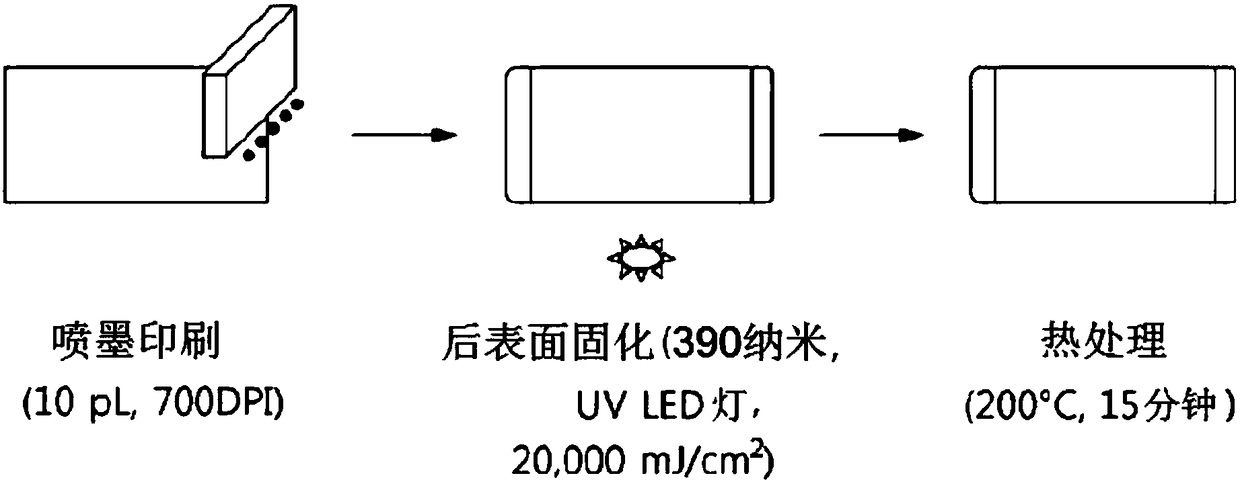

Method used

Image

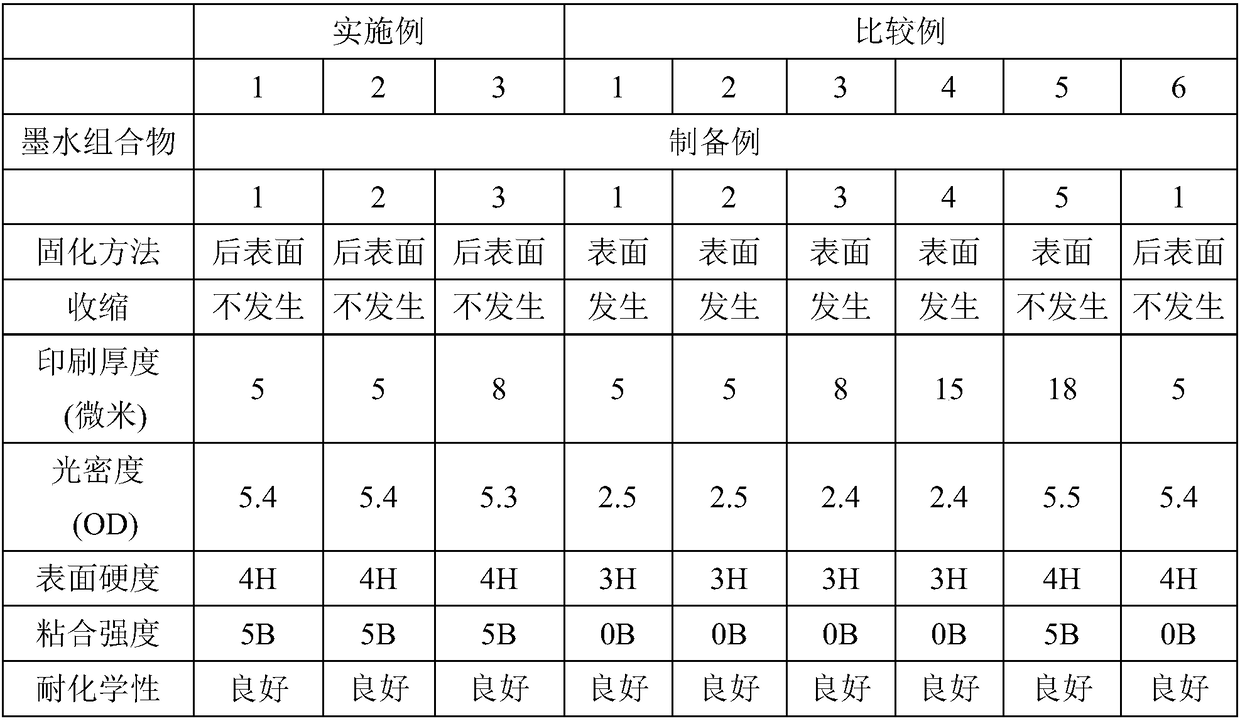

Examples

preparation example 1

[0087] Preparation Example 1. Preparation of UV Curable Ink Composition

[0088] 60.00 g of pigment dispersion (manufactured by Tokushiki Co., Ltd., 18.00 g of carbon black, 3.60 g of acrylic dispersant and 38.40 g of 1,6-hexanediol dimethacrylate), 10.00 g of melamine acrylate Oligomer (Miramer SC9610, manufactured by Miwon Professional Chemical Co., Ltd.), 19.90 g of binder solution (17.90 g of 2-hydroxyethyl acrylate as the second reactive monomer and 2.00 g of Resin PD7610, manufactured by Almatex Corporation), 3.00 g of KBM-403 (manufactured by Shin-Etsu Chemical Co., Ltd.) as an adhesive strength enhancer, 7.00 g of photoinitiators (5.00 g of ), 0.05 g of BYK-307 as a surfactant and 0.05 g of hydroquinone monomethyl ether (MEHQ) as a polymerization inhibitor were mixed, and then the mixture was stirred for 6 hours to prepare 100 g of an ultraviolet curable ink combination thing.

preparation example 2

[0089] Preparation Example 2. Preparation of UV Curable Ink Composition

[0090]In addition to using 10.00 g of epoxy acrylate oligomer (Miramer SC6400, manufactured by Miwon Specialty Chemical Co., Ltd.) instead of 10.00 g of melamine acrylate oligomer (Miramer SC9610, manufactured by Miwon Specialty Chemical Co., Ltd.), the An ultraviolet curable ink composition for a frame was prepared in the same manner as in Example 1.

preparation example 3

[0091] Preparation Example 3. Preparation of UV Curable Ink Composition

[0092] 50.00 g of pigment dispersion (15.00 g of carbon black, 3.00 g of acrylic dispersant and 32.00 g of hexanediol dimethacrylate), 10.00 g of melamine acrylate oligomer (MiramerSC9610, produced by Miwon Professional Chemical Co., Ltd.), 29.90 g of binder solution (17.90 g of 2-hydroxyethyl acrylate as the second reactive monomer, 10.00 g of trimethylolpropane triacrylic acid as the second reactive monomer Ester and 2.00 g of PD7610 as an epoxy resin, manufactured by Almatex Corporation), 3.00 g of KBM-403 as an adhesive strength enhancer (manufactured by Shin-Etsu Chemical Co., Ltd.), 7.00 g of photoinitiator ( 5.00g of Irgacure907 and 2.00g of ), 0.05 g of BYK-307 as a surfactant and 0.05 g of hydroquinone monomethyl ether (MEHQ) as a polymerization inhibitor were mixed, and then the mixture was stirred for 6 hours to prepare 100 g of an ultraviolet curable ink combination thing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com