Hoisting device and hoisting method for serpentine tube panel

A hoisting device and serpentine tube technology, which is applied in the direction of boiler support/positioning device, transportation and packaging, load hanging components, etc., can solve the problems of serpentine tube deformation, poor rigidity, easy deformation, etc., to prevent deformation, Stable and reliable connection, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

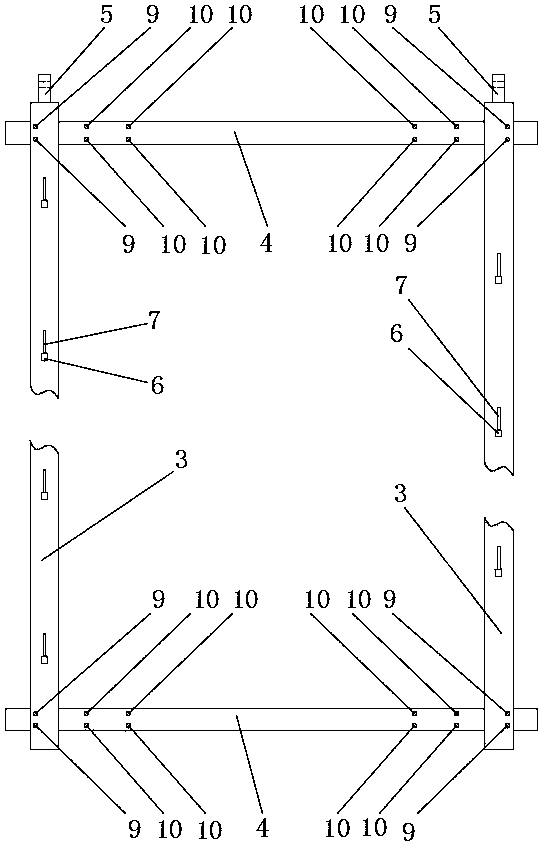

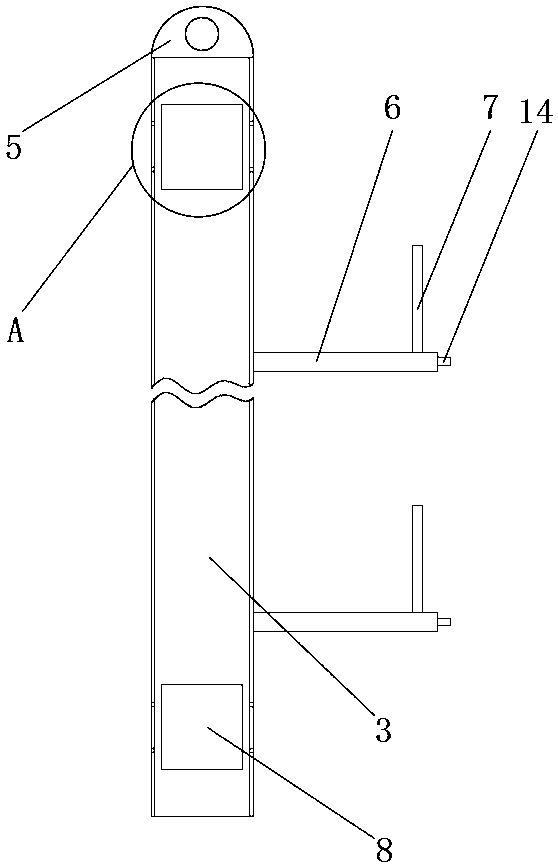

[0026] like figure 1 , 2 As shown in and 8, the hoisting device for the serpentine tube panel, the serpentine tube panel consists of several straight pipes 1 and several elbows 2, including two left and right vertical beams 3 and two upper and lower beams 4, the four are fixedly connected to form a A rectangular frame, two vertical beams 3 with lifting lugs 5 at the top, a number of horizontal support rods 6 are fixedly installed on the two vertical beams 3, the horizontal support rods 6 are covered with rubber sleeves (not shown in the figure), the horizontal support rods 6 is used to contact the outer surface of the straight tube 1 of the serpentine tube screen and form a vertical support. The cross-sectional shape of the horizontal support rod 6 is rectangular, and one of its horizontal planes is used to contact the outer surface of the straight tube 1 of the serpentine tube screen. The horizontal support rods 6 on the two vertical beams 3 form upper and lower staggered fl...

Embodiment 2

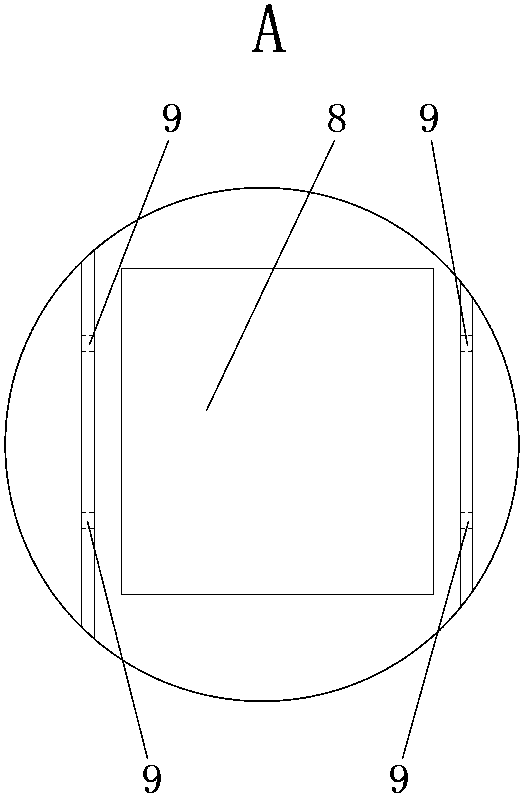

[0028] like Figures 1 to 3 , 6 and 7, on the basis of embodiment 1, the vertical beam 3 and the cross beam 4 are I-beams, and the upper and lower ends of the vertical beam 3 webs are provided with installation through holes 8, and at the vertical beam 3 two ends Two connection holes 9 are provided on the board corresponding to the positions of the installation through holes 8, and at least two groups of matching holes 10 are respectively provided at the left and right ends of the two ends of the beam 4, and three groups of matching holes 10 are specifically set here, namely Three groups of matching holes 10 are respectively provided at the left end and the right end of each end plate, and each group includes two matching holes 10, and there is a distance between adjacent groups of matching holes 10, and the left and right ends of the crossbeam 4 are correspondingly inserted into the two vertical beams 3 at the same time. In the installation through hole 8 at the end, the two ...

Embodiment 3

[0030] like figure 2 , 4 As shown in and 5, on the basis of Embodiment 2, the end of the horizontal support rod 6 is provided with a vertical adjustment through hole 11, and the limit rod 7 is inserted in the adjustment through hole 11, and is matched, and the limit The upper end and the lower end of the rod 7 are respectively provided with a limit hole 12, and the end of the horizontal support rod 6 is provided with an axial step hole 13, and an axial step shaft 14 is installed in the step hole 13, and the step shaft 14 includes an annular step. And the shaft part, the step shaft 14 is covered with a compression spring 15, when the step shaft 14 is installed in the step hole 13, the compression spring 15 can be installed in the step hole 13 first, and then pass through the shaft part, and the shaft parts pass through in turn Over compress the spring 15 and the annular step, and then weld the annular step and the shaft. The two ends of the compression spring 15 are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com