Assembled type foundation unit

A prefabricated, foundation technology, applied in infrastructure engineering, construction, etc., can solve the problems affecting the bearing capacity and safe use of the house, the complicated operation of the house foundation, the sinking of the house foundation, etc., to achieve ingenious structure, avoid twisting and bending. , the effect of stable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

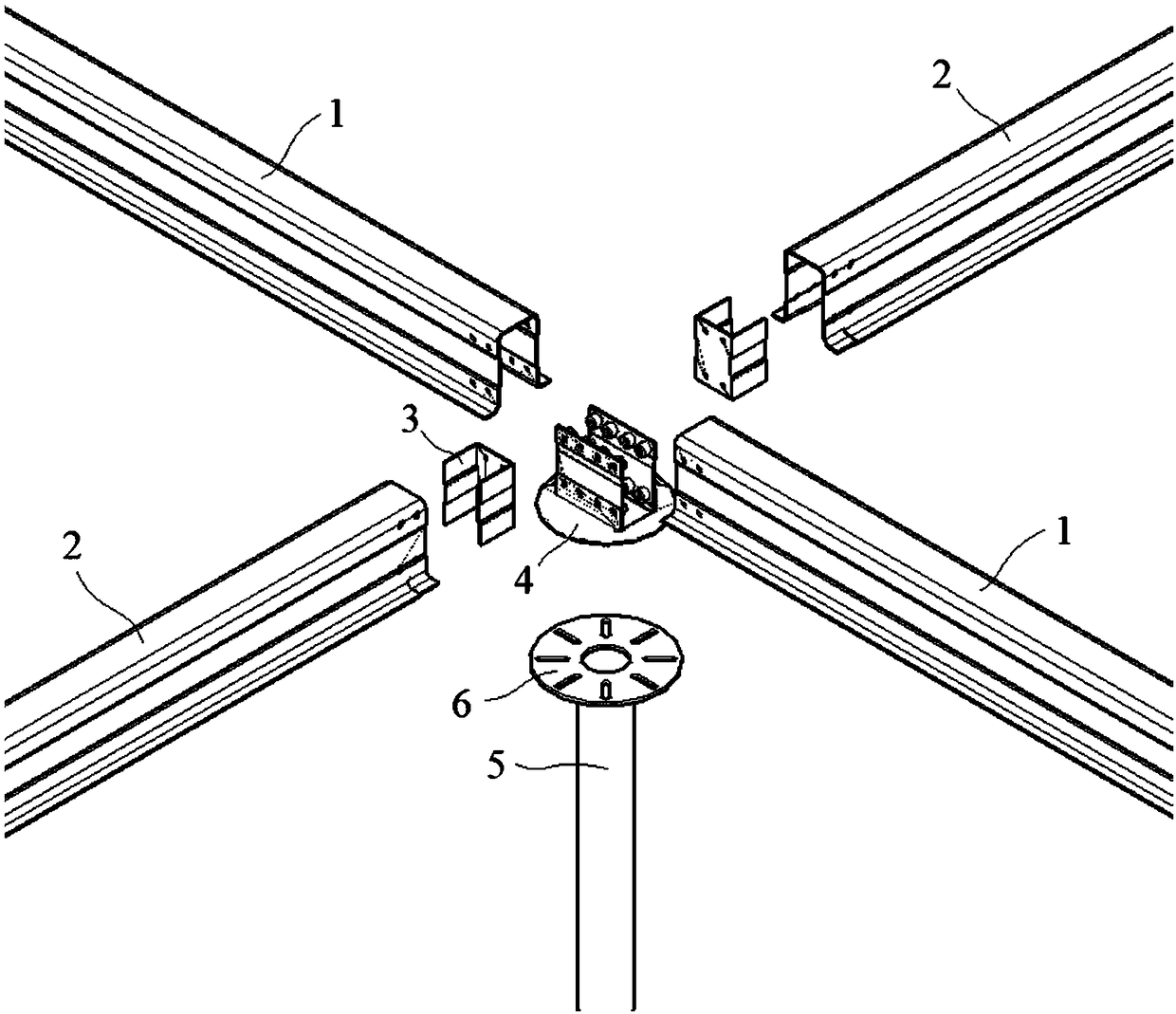

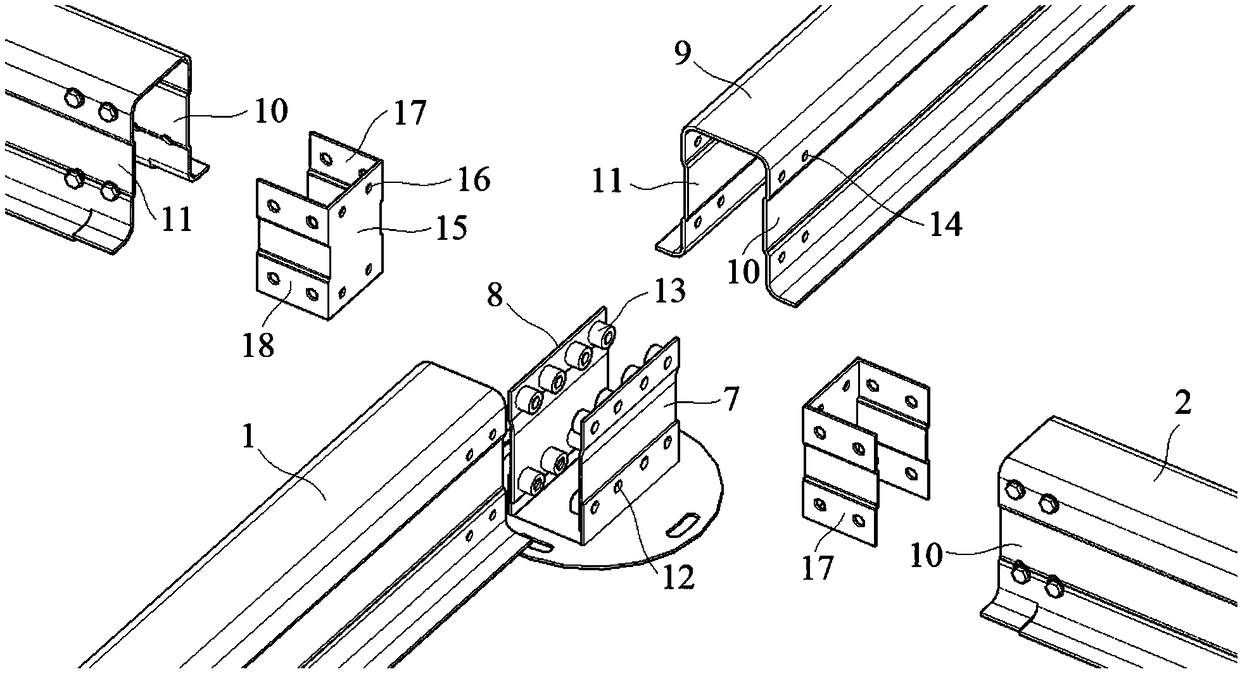

[0025] Embodiment 1: An assembled foundation unit, including 2 X beams 1, 2 Y beams 2, 2 connectors 3, connection plates 4 and ground piles 5, the 2 X beams 1 are connected with the connection plates 4 respectively Installation and connection, the two Y beams 2 are respectively installed and connected to the connecting plate 4 through two connecting pieces 3, the ground pile 5 is installed on the lower surface of the connecting plate 4 through a mounting plate 6, and the upper surface of the connecting plate 4 is symmetrical A first vertical plate 7 and a second vertical plate 8 are provided, the two ends of the first vertical plate 7 are respectively installed and connected with two X beams 1, and the two ends of the second vertical plate 8 are respectively installed with two X beams 1 connect;

[0026] The X beam 1 and the Y beam 2 further include a top plate 9 and a first side plate 10 and a second side plate 11 positioned on both sides of the top plate 9, and the first ver...

Embodiment 2

[0031] Embodiment 2: An assembled foundation unit, including 2 X beams 1, 2 Y beams 2, 2 connectors 3, connection plates 4 and ground piles 5, the two X beams 1 are respectively connected to the connection plates 4 Installation and connection, the two Y beams 2 are respectively installed and connected to the connecting plate 4 through two connecting pieces 3, the ground pile 5 is installed on the lower surface of the connecting plate 4 through a mounting plate 6, and the upper surface of the connecting plate 4 is symmetrical A first vertical plate 7 and a second vertical plate 8 are provided, the two ends of the first vertical plate 7 are respectively installed and connected with two X beams 1, and the two ends of the second vertical plate 8 are respectively installed with two X beams 1 connect;

[0032] The X beam 1 and the Y beam 2 further include a top plate 9 and a first side plate 10 and a second side plate 11 positioned on both sides of the top plate 9, and the first ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com