A pump impeller with secondary splitter vanes

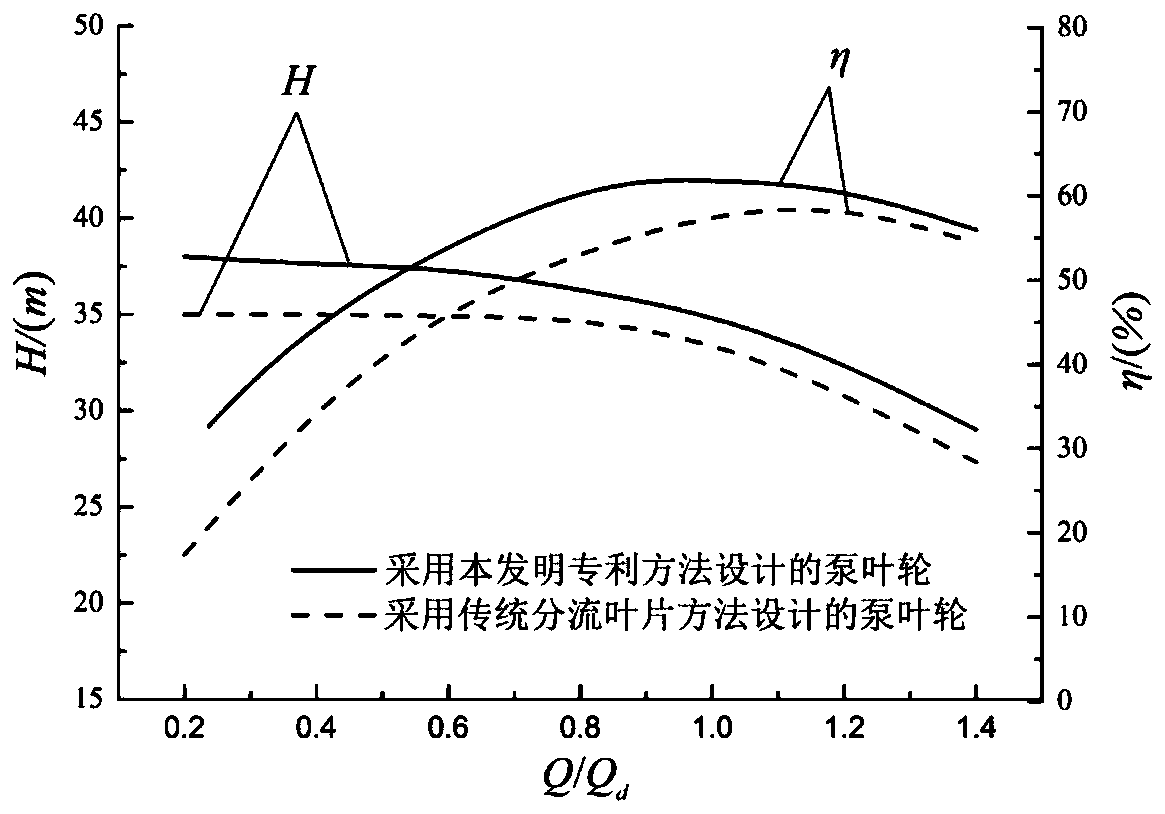

A technology of splitting vanes and pump impellers, which is applied to the components, pumps, and pump components of pumping devices for elastic fluids, and can solve problems such as low pump operation efficiency, increased impeller hydraulic loss, and uneven flow rate flowing into the pump body. , to achieve the effect of improving operating efficiency, increasing head coefficient, and reducing jet-wake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] A centrifugal pump with a specific speed of 48, its design parameters are: design flow Q d =16m 3 / h, head H=35m, speed n=2860r / min. The main geometric parameters of the impeller are: impeller outlet diameter D 2 =220mm, impeller inlet diameter D 1 =50mm, impeller outlet width b 2 = 6mm.

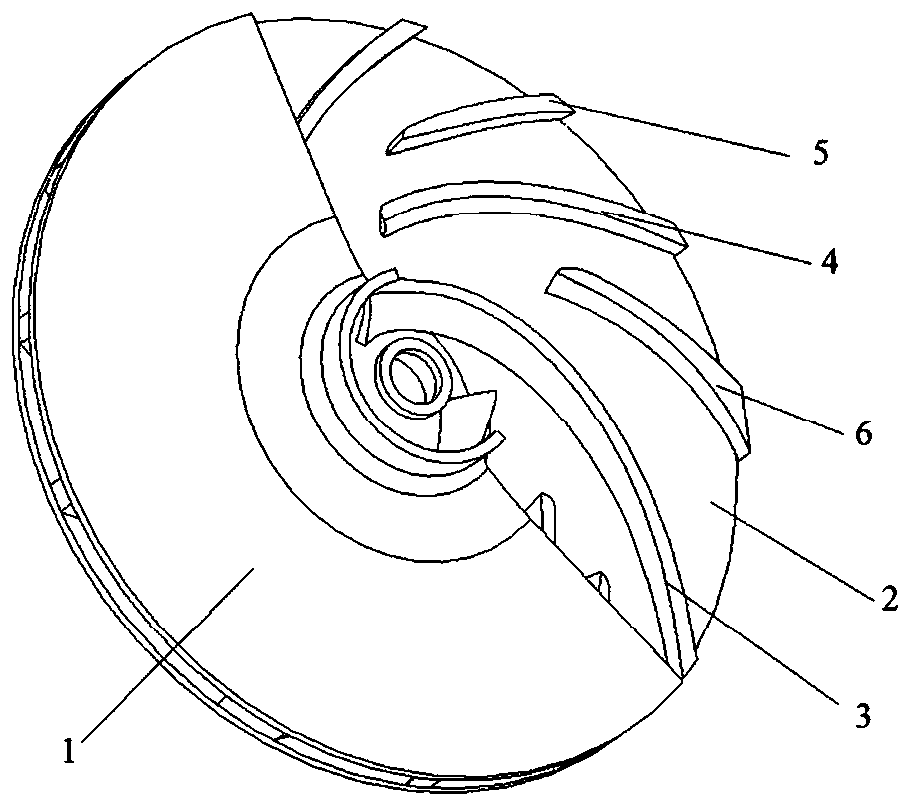

[0025] as attached figure 1 As shown, a pump impeller with secondary splitter blades includes a front cover plate, a rear cover plate, long blades, primary splitter blades, secondary splitter blade 1 and secondary splitter blade 2, all blades are twisted blades, and The number of leaves is 3.

[0026] as attached figure 1 As shown, the long blades are evenly distributed in the circumferential direction of the impeller; the primary splitter blade is located in the flow channel formed by two adjacent long blades; the secondary splitter blade is located in the flow channel between the suction surface of the long blade and the pressure surface of the primary splitter blade; Second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com