Crash dampers for high-speed rotating machinery

A high-speed rotation and damper technology, applied in mechanical equipment, non-rotational vibration suppression, spring/shock absorber, etc., can solve problems such as poor working environment, environmental protection, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

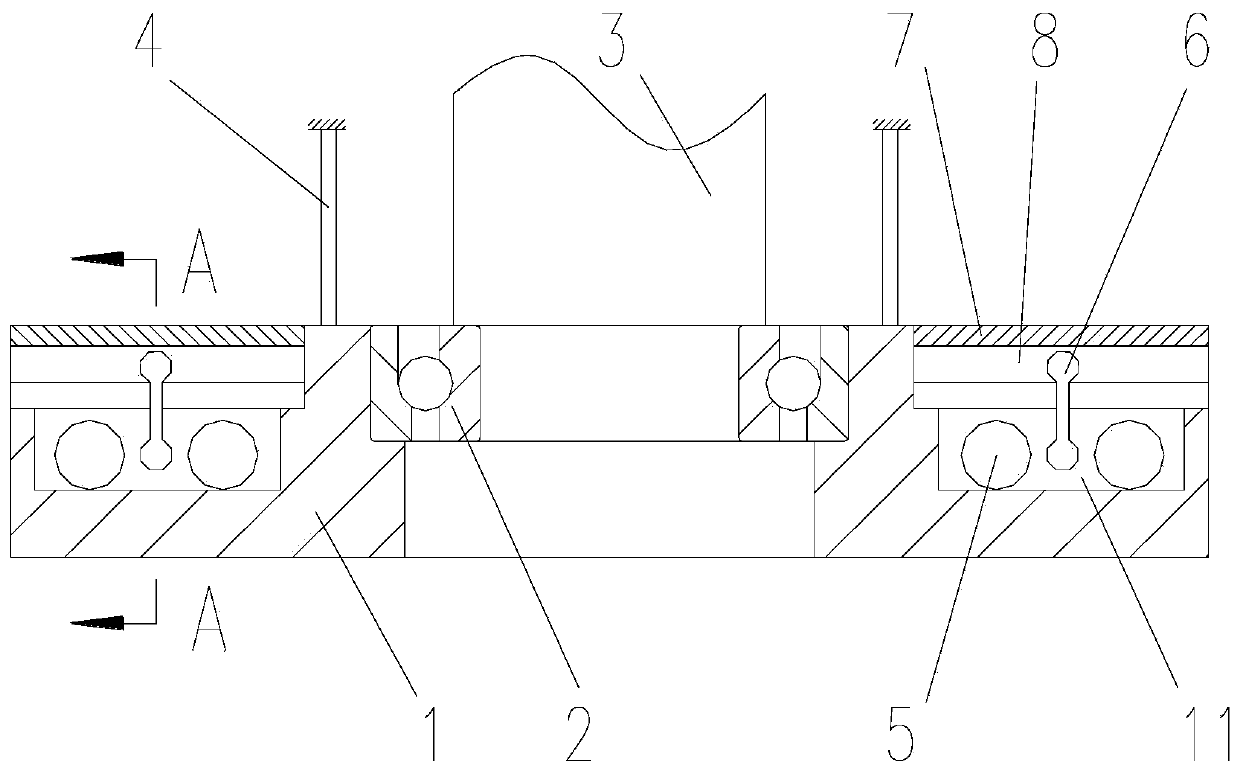

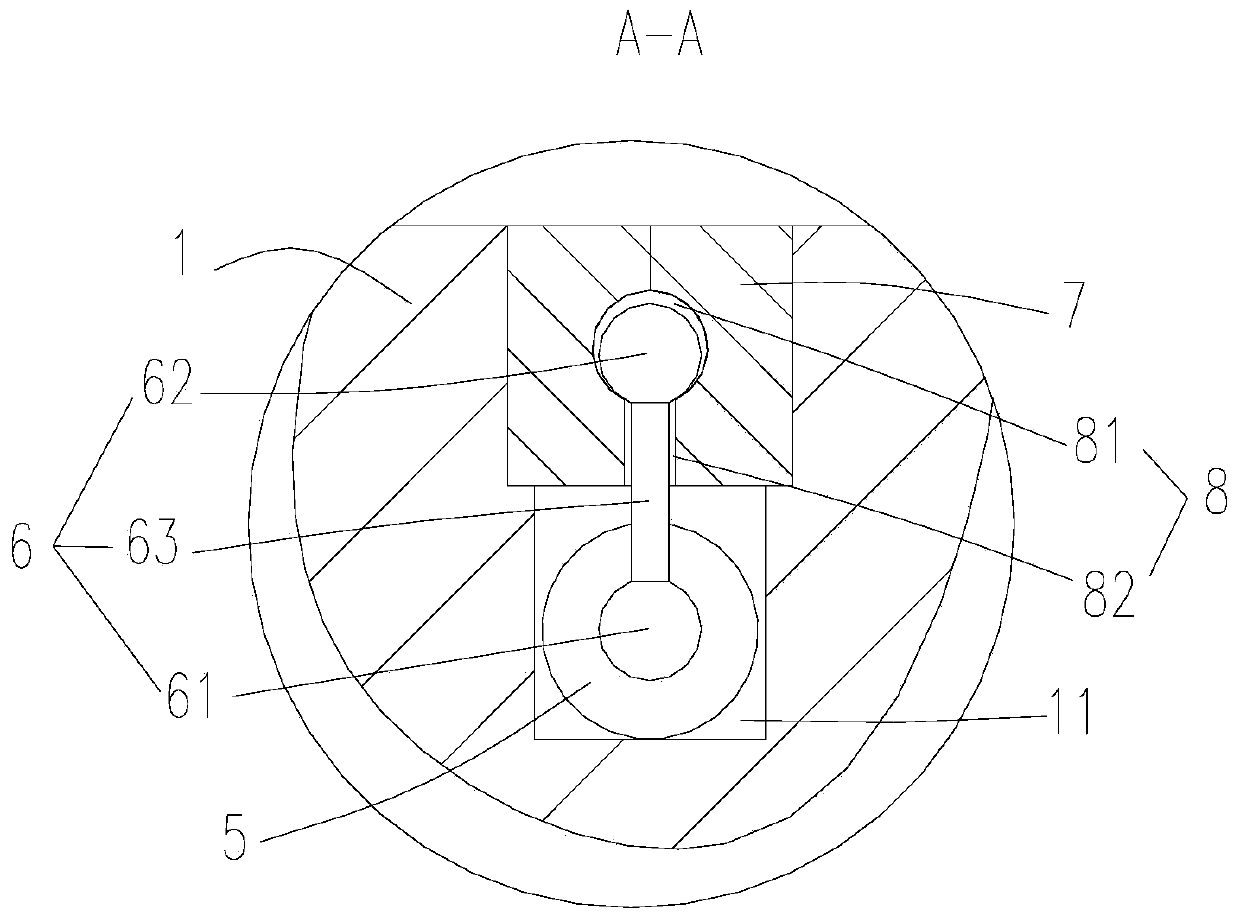

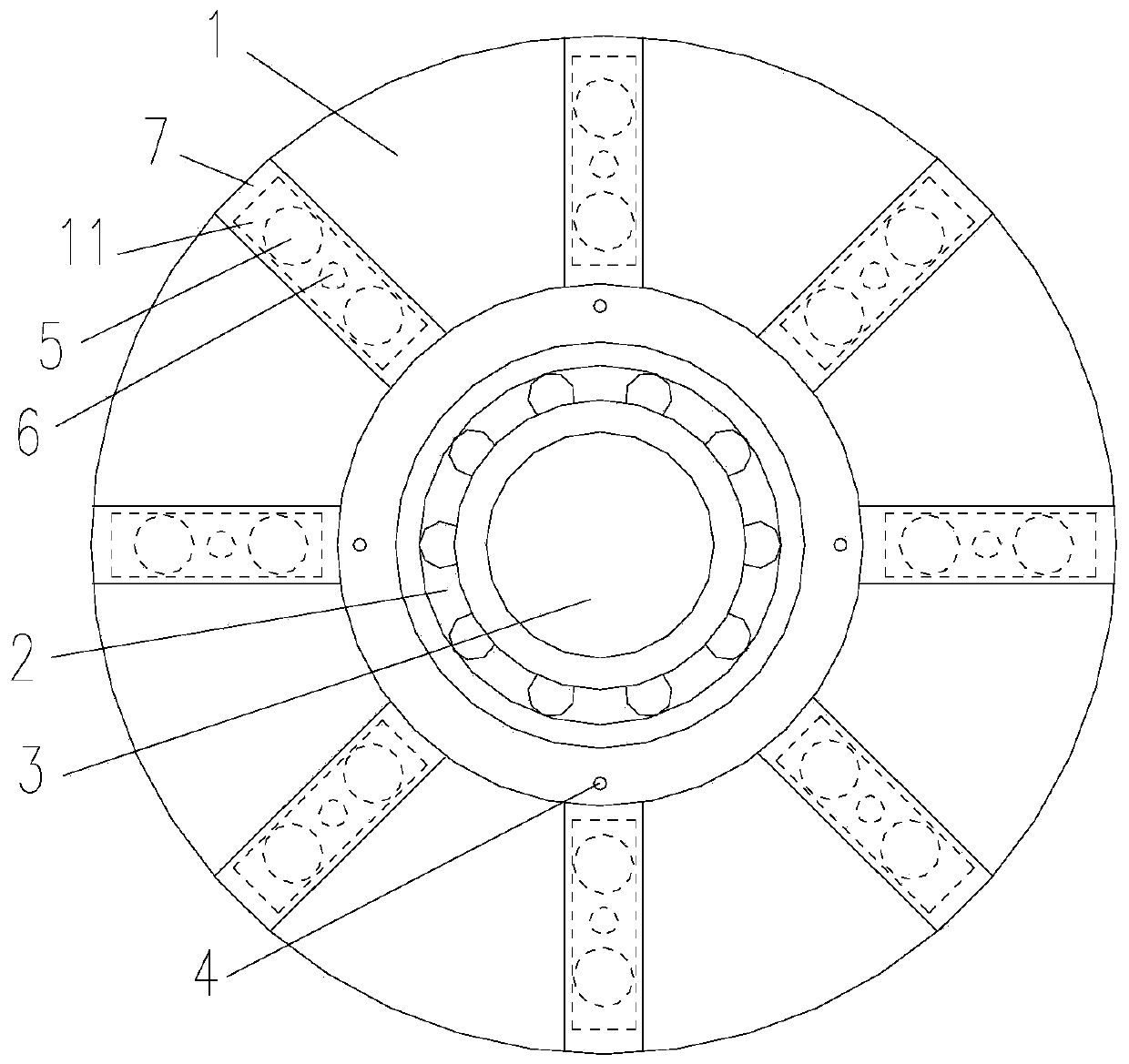

[0018] Such as Figure 1~3 As shown, a collision damper for high-speed rotating machinery includes a bearing housing 1, a support shaft 4, a number of large collision balls 5 and a number of small collision body combinations 6, the inner ring of the bearing 2 on the bearing housing 1 and the rotating shaft 3 is fixedly connected, the bearing 2 is an angular contact ball bearing 2, and radially and axially supports the lower end of the rotating shaft 3, one end of the supporting shaft 4 is fixedly connected with the bearing seat 1, and the other end is fixed on the housing, in order to ensure The bearing seat 1 only swings without rotation, which improves the stability of the damper in use. The number of the support shafts 4 is four, and the four support shafts 4 are evenly distributed along the circumferential direction of the rotating shaft 3. The bearing seat 1 is provided with long grooves 11, the long grooves 11 are distributed along the radial direction of the rotating sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com